Effective threading tools for CNC lathes, Swiss-type lathes, and multitasking machines

Standard items cover a wide variety of threading inserts

Applications & Features

Applications

Features

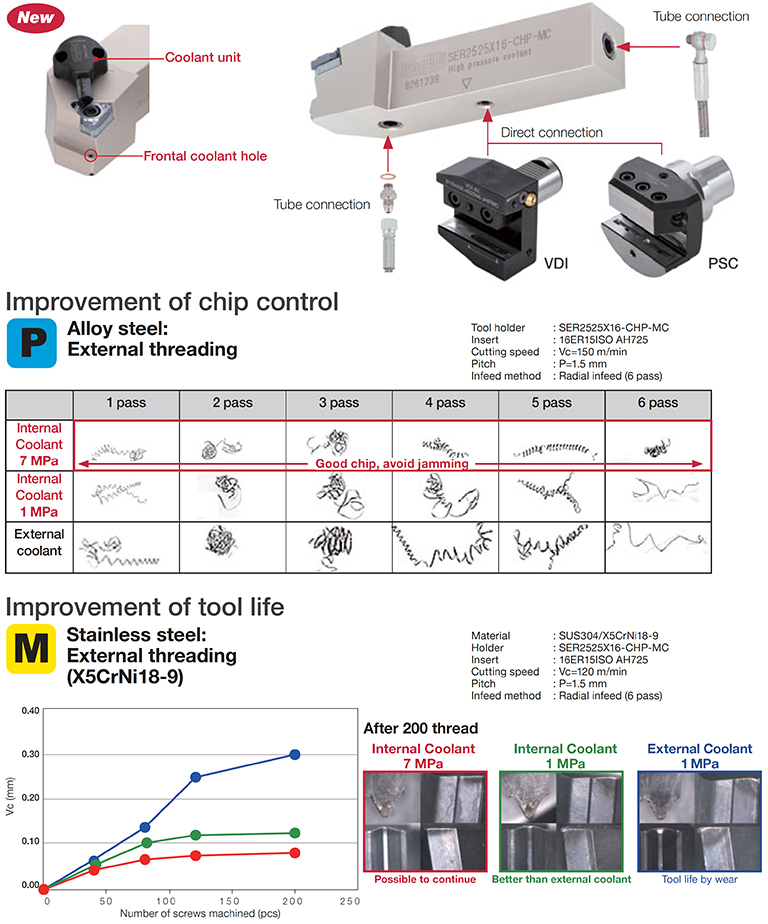

1. Internal coolant tool holder

• Optimized two streams of high-pressure coolant jets to maximize productivity.

• Applicable direct connection with tube free.

Inserts & Grades

Inserts

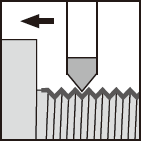

External threading Inserts

- Standard inserts covering a wide variety of thread types

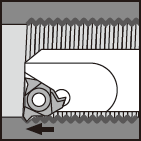

Internal threading Inserts

- Standard inserts covering a wide variety of thread types

Main Grades

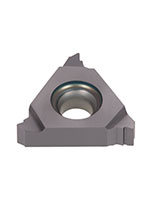

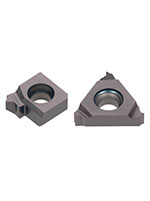

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

SH725

![]()

![]()

- P20 – P30 / M20 – M30

- High wear resistance

- Designed for machining steel and stainless steel

AH8015

![]()

![]()

![]()

![]()

![]()

- M01 – M20 / S10 – S20

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

Toolholders

Practical examples

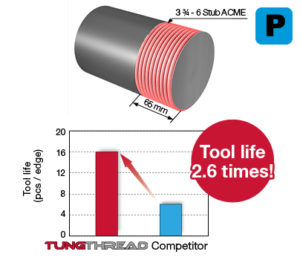

Example #1

General Engineering

| Part: | Shaft Parts |

| Material: | 42CrMo4/SCM440 |

| Toolholder: | STVOL2525M4 (Vertical style) |

| Insert: | TNMC43NT6PSTUBPT (3 croner) |

| Grade: | AH725 |

| Cutting conditions: | Thread shape = Stub ACME (3 ¾ (95.25mm)) Vc = 70 m/min (230 sfm) TPI = 6 TPI (4.23mm) Number of passes = 30 Application: External Threading Coolant: Wet Machine: NC Lathe |

Standard cutting conditions

TungThread

| ISO | Workpiece Workpiece materials |

Hardness | Cutting speed Vc (m/min) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AH8015 | T05HP | T05TP | AH725 | T313V | NS9530 | TH10 | BX330 | |||

| Steel / Alloy steel S45C, SCM440, etc. C45, 42CrMoS4, etc. |

< 200 HB | 80 – 180 | 100 – 200 | 100 – 200 | 80 – 180 | 100 – 200 | 150 – 200 | – | – | |

| > 200 HB | 60 – 160 | 100 – 150 | 100 – 150 | 60 -160 | 100 – 150 | 100 – 170 | – | – | ||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | 50 – 130 | 70 – 130 | 70 – 130 | 50 – 130 | 70 – 130 | – | – | – | |

| Cast iron FC250, FC300, etc. 250, 300, etc. |

– | 60 – 150 | 70 – 150 | 70 – 150 | 50 – 100 | 70 – 150 | – | 70 – 90 | – | |

| Aluminium | – | – | – | – | 100 – 500 | – | ||||

| Heat-resistance alloys | – | 20 – 80 | – | – | – | 10 – 40 | – | |||

| High hardened steel | 50 – 60 HRC | – | – | – | 10 – 30 | 50 – 200 | ||||

TungT-Clamp

| ISO | Workpiece Workpiece materials |

Hardness | Grade | Application | Cutting speed Vc (m/min) |

Pitch (mm) | Threads per inch (TPI) |

|---|---|---|---|---|---|---|---|

| Steel / Alloy steel S45C, SCM440, etc. C45, 42CrMoS4, etc. |

< 200 HB | AH725 | Threading | 80 – 180 | Internal 2.11 – 5.08 External 1.27 – 4.23 |

Internal 5 – 12 External 6- 20 |

|

| > 200 HB | AH725 | Threading | 60 -160 | Internal 2.11 – 5.08 External 1.27 – 4.23 |

Internal 5 – 12 External 6- 20 |

||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | AH725 | Threading | 50 – 130 | Internal 2.11 – 5.08 External 1.27 – 4.23 |

Internal 5 – 12 External 6- 20 |

TetraMini-Cut

| ISO | Workpiece Workpiece materials |

Hardness | Priority | Grade | Cutting speed Vc (m/min) |

Pitch (mm) | Threads per inch (TPI) |

|---|---|---|---|---|---|---|---|

| Steel / Alloy steel S45C, SCM440, etc. C45, 42CrMoS4, etc. |

< 200 HB | First choice | SH725 | 60 – 150 | 0.4 – 2.0 | 64 – 12 | |

| Fracture resistance | AH725 | 60 – 150 | 0.8 – 3.0 | 32 – 8 | |||

| > 200 HB | First choice | SH725 | 60 – 150 | 0.4 – 2.0 | 64 – 12 | ||

| Fracture resistance | AH725 | 60 – 150 | 0.8 – 3.0 | 32 – 8 | |||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | First choice | SH725 | 50 – 80 | 0.4 – 2.0 | 64 – 12 | |

| – | Fracture resistance | AH725 | 50 – 80 | 0.8 – 3.0 | 32 – 8 | ||

| Cast iron FC250, FC300, etc. 250, 300, etc. |

– | First choice | AH725 | 50 – 100 | 0.8 – 3.0 | 32 – 8 | |

| – | Sharpness | SH725 | 50 – 100 | 0.4 – 2.0 | 64 – 12 | ||

| Superalloys Ti-6AI-4V, Inconel718, etc. |

– | First choice | SH725 | 30 – 100 | 0.4 – 2.0 | 64 – 12 | |

| – | Fracture resistance | AH725 | 30 – 100 | 0.8 – 3.0 | 32 – 8 |

DuoJust-Cut

| ISO | Workpiece material | Hardness | Grade | Cutting speed Vc (m/min) | Pitch (mm) |

Threads per inch (TPI) |

|---|---|---|---|---|---|---|

| Steel / Alloy steel S45C, SCM440, etc. C45, 42CrMoS4, etc. |

< 200HB | SH725 | 50 – 200 | 0.2 – 1.5 | 127 – 16 | |

| > 200HB | SH725 | 50 – 200 | 0.2 – 1.5 | 127 – 16 | ||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | SH725 | 50 – 200 | 0.2 – 1.5 | 127 – 16 | |

| Aluminium alloys A5056, A6061, etc. |

– | SH725 | 150 – 200 | 0.2 – 1.5 | 127 – 16 | |

| Copper alloy C2600, C280C, etc. |

– | SH725 | 100 – 200 | 0.2 – 1.5 | 127 – 16 | |

| Superalloys Ti-6AI-4V, Inconel718, etc. |

– | SH725 | 30 – 80 | 0.2 – 1.5 | 127 – 16 |

TinyMini-Turn Internal threading

| ISO | Workpiece material | Hardness | Grade | Cutting speed Vc (m/min) | Number of passes | ||||

|---|---|---|---|---|---|---|---|---|---|

| Pitch (mm) | |||||||||

| 0.5 | 0.75 | 1 | 1.25 | 1.5 | |||||

| Steel / Alloy steel S45C, SCM440, etc. C45, 42CrMoS4, etc. |

< 200HB | SH725 | 40 – 140 | 6 – 8 | 8 – 10 | 10 – 12 | 12 – 15 | 15 – 18 | |

| > 200HB | SH725 | 40 – 140 | 6 – 8 | 8 – 10 | 10 – 12 | 12 – 15 | 15 – 18 | ||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | SH725 | 40 – 140 | 8 | 10 | 12 | 15 | 18 | |

| Cast iron FC250, FC300, etc. 250, 300, etc. |

– | SH725 | 30 – 100 | 7 | 9 | 12 | 14 | 17 | |

| Aluminium alloys, Copper alloy Si < 12% |

– | SH725 | 90 – 200 | 6 | 8 | 10 | 12 | 15 | |

For more information about this product, visit our online e-catalog or download the product report: