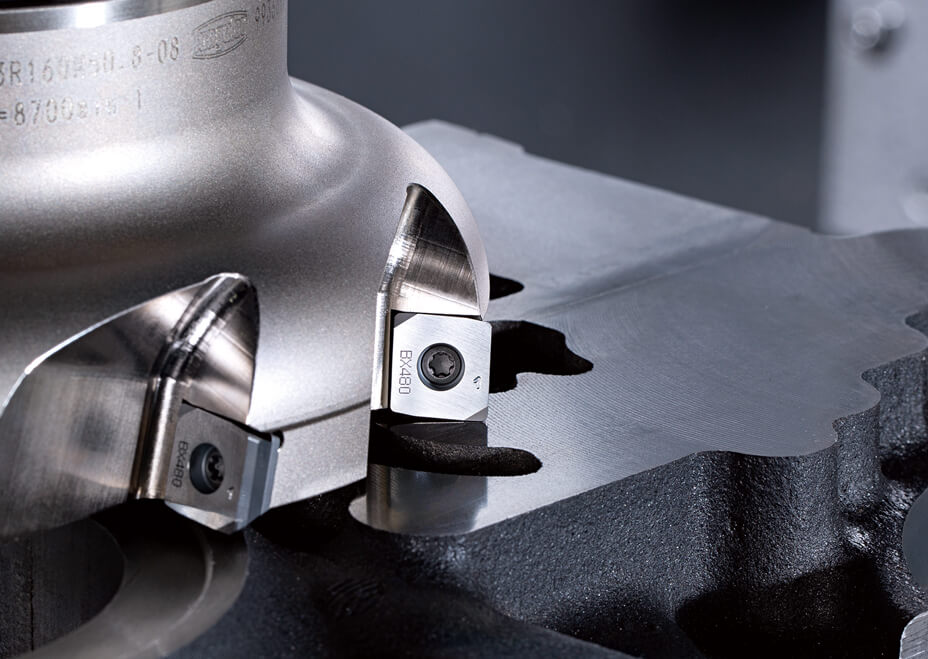

Ideal for High-Speed Finishing of Cast Iron. Wiper insert is also available.

Iwaki, August 2024, Tungaloy Corporation (President: Satoshi Kinoshita, Headquarters: Iwaki City, Fukushima Prefecture) is pleased to announce the addition of CBN inserts for high-speed cast iron finishing to its “TPW / EPW Type” milling cutter series.

Overview

The “TPW / EPW Type” series features a 4-corner insert design that balances sharpness and edge strength, enabling high-precision, high-efficiency machining. With a 90-degree cutting edge angle (KAPR), these cutters excel not only in square shoulder milling but also in face milling around obstacles and fixtures. The inserts are available in four types, including the versatile “MJ Type,” ensuring stable performance across a wide range of materials. The cutter bodies come in both bore type “TPW Type” and shank type “EPW Type,” covering tool diameters from φ32 to φ200mm (from φ1.260” to φ7.874”). Additionally, both of coarse pitch type and close pitch type are available, allowing users to select the optimal tool based on their machining conditions.

The new addition to the “TPW / EPW Type” series includes CBN inserts designed for high-speed cast iron finishing. In addition to the economical 2-corner standard insert, a wiper insert option is also available to achieve excellent surface finish. The insert grade is High-content CBN “BX480,” which consists of densely bonded medium-grain CBN. This grade offers high hardness, toughness, and superior thermal conductivity, making it suitable for high-speed machining at cutting speeds (Vc) exceeding 1000m/min.

The expansion of the CBN inserts for high-speed cast iron finishing will enable the “TPW / EPW Type” cutters to significantly contribute to reducing machining time and improving productivity across a wider range of industries through high-efficiency machining.

Product information

No. 358S1-G (Metric)

TAW / EAW, TPW / EPW