TungCap Cost Saving Simulator

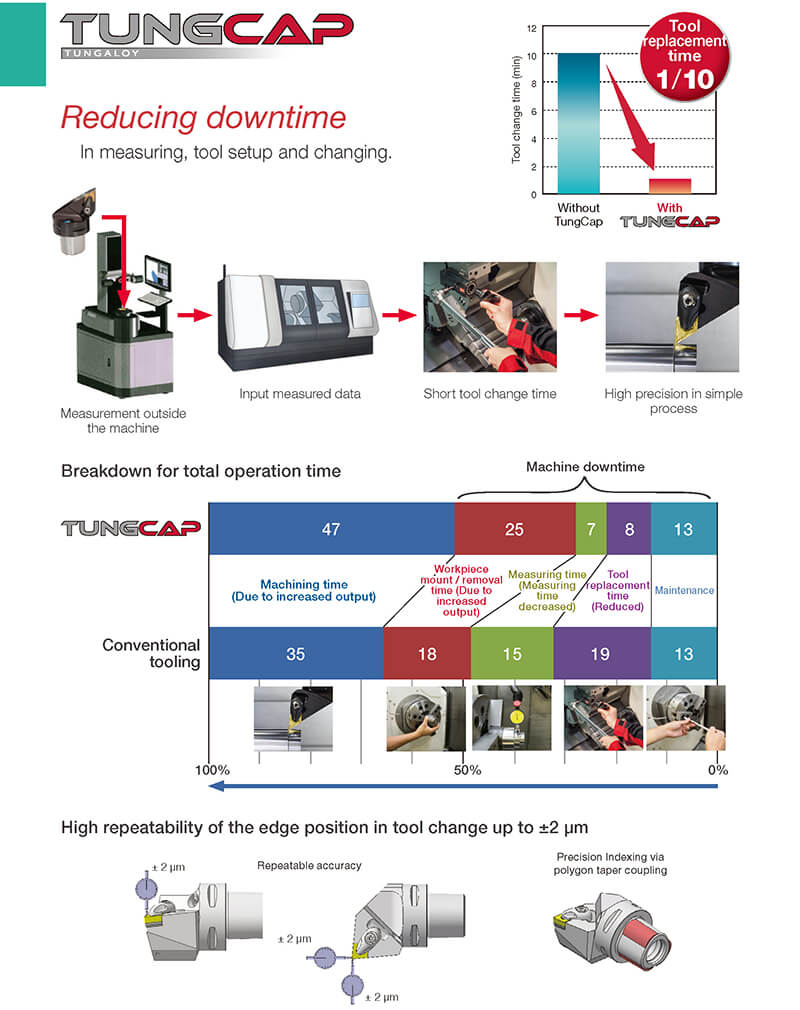

Le système d'outillage à changement rapide TungCap est un excellent moyen d'économiser des coûts pour les opérations de tour CNC et de machine multi-tâches, ce qui permet des processus de changement d'outil rationalisés et une utilisation maximale de la machine.

Ce simulateur vous permet d'avoir un aperçu des heures de travail et des coûts que le système d'outillage TungCap peut économiser, ainsi que de la productivité que vous pouvez améliorer.

Entrez simplement vos données actuelles dans les cellules ci-dessous, le simulateur calculera automatiquement les heures de travail, les coûts et la productivité que vous pouvez améliorer chaque année avec TungCap.

Tool change operations by TungCap tooling

Data for routine insert change

TungCap tooling will be saving …

Labor costs |

38,333.333Dollar per year |

|---|---|

Machining time (in hours) |

1,533.333hours per year |

(of which hours saved from insert changes+offsetting) |

1,000hours |

(of which hours save from tool setup change) |

533.333hours |

Cost saved for test cut workpieces |

1,760Dollar per year |

Total value of additional parts produced annually for the time saved |

36,800Dollar per year |

(Total number of additional parts produced annually for the time saved) |

46,000units per year |

Total costs saved by TungCap tooling |

76,893.333Dollar per year |

Tool change operations by TungCap tooling