Applications & Fonctionnalités

Applications

Fonctionnalités

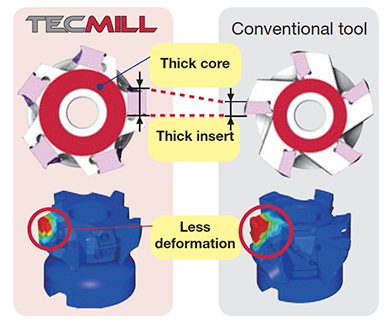

1. Fonctionnement fiable

– Fraise très rigide avec noyau plus épais

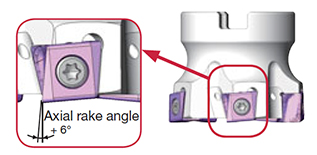

2. Plaquette à 4 arêtes de coupe

– Les grands angles de coupe et d’inclinaison réduisent les efforts de coupe

Plaquettes & Nuances

Plaquettes

LMMU11/16-MJ

- Profondeur de coupe maximale

– LNMU11-MJ: 9.7 mm

– LNMU16-MJ: 15.1 mm - Plaquettes à 4 arêtes de coupe

- Forces de coupe faibles et coupe stable et lisse

Nuances principales

AH3135

![]()

![]()

- Haute résistance à la rupture

- Convient pour l’usinage des aciers et des aciers inoxydables dans des conditions de coupe générale

AH725

![]()

![]()

![]()

![]()

- Bel équilibre entre résistance à l’usure et à l’écaillage

- Convient pour l’usinage des aciers et des aciers inoxydables dans des conditions de coupe générales

AH120

![]()

- Bel équilibre entre résistance à l’usure et à la rupture

- Convient pour l’usinage des aciers, des aciers inoxydables et de la fonte dans des conditions de coupe générales

AH3225

![]()

![]()

- Bel équilibre entre résistance à l’usure et à la rupture

- Convient pour les aciers et l’inox

AH8015

![]()

![]()

![]()

![]()

![]()

-

Bel équilibre entre résistance à l’usure et à la rupture

-

Premier choix pour l’usinage des alliages résistants à la chaleur dans des conditions de coupe générales

Corps d'outil

Type de tige

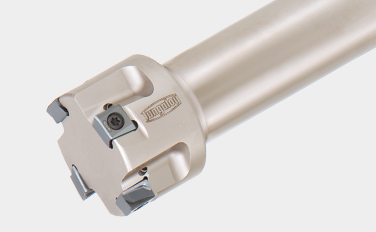

EPM11 (ø32 – ø80mm)

Porte-outil de type cylindrique pour le fraisage d’épaulements

Exemples pratiques

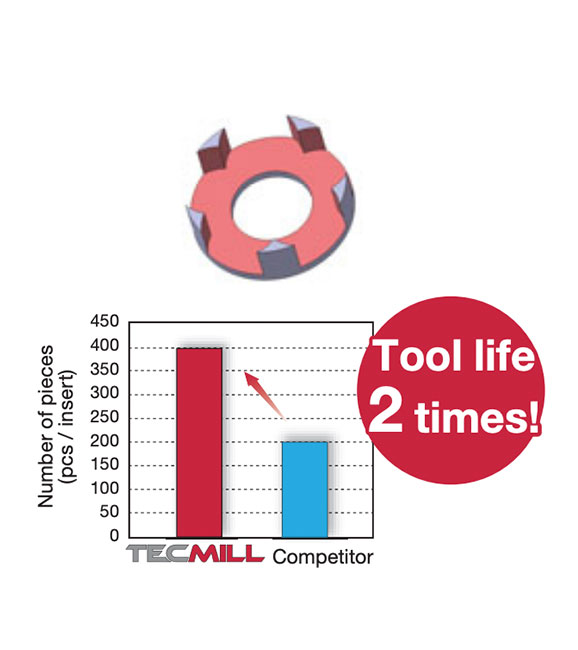

Exemple #1

Industrie automobile

| Partie: | Porte-planétaire |

| Matériau: | S35C |

| Corps d’outil: | Spécial (ø78 mm, z = 2) |

| Plaquette: | LMMU160932PNER-MJ |

| Nuance: | AH3135 |

| Conditions de coupe: | Vc = 250 (m/min) fz = 0.1 (mm/t) Vf = 200 (mm/min) ap = 40 (mm) ae = 30 (mm) Application: plongée Liquide de refroidissement : à sec Machine: Vertical M/C, BT50 |

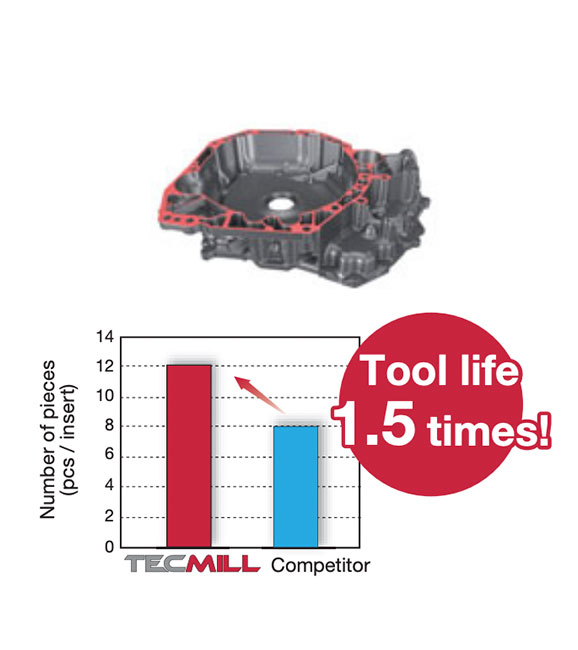

Exemple #2

Industrie automobile

| Partie: | Boîtier de carter d’engrenage |

| Matériau: | FCD450 / GGG45 / 450-10S |

| Corps d’outil: | TPM11R200U0075A05 (ø50.8 mm, z = 5) |

| Plaquette: | LMMU110708PNER-MJ |

| Nuance: | T1215 |

| Conditions de coupe: | Vc = 175 (m/min) fz = 0.15 (mm/t) Vf = 840 (mm/min) ap = 4 (mm) ae = 20 (mm) Application: fraisage 90° Liquide de refroidissement : à sec Machine: Vertical M/C, BT50 |

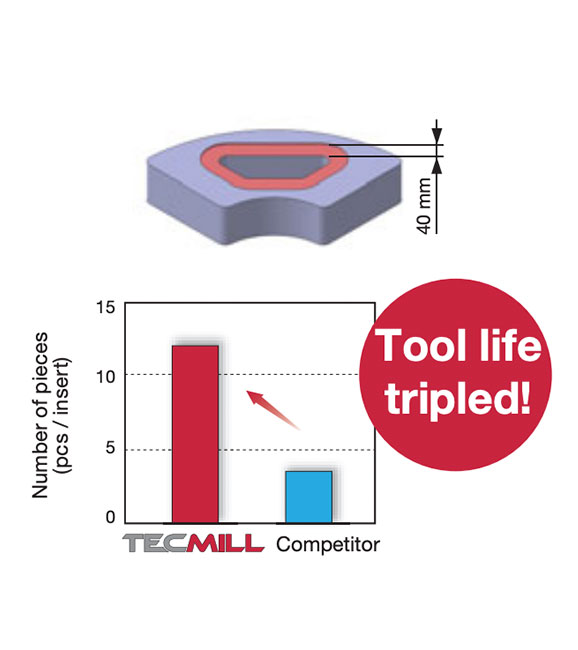

Exemple #3

ingénierie générale

| Partie: | Case |

| Matériau: | Aciers inoxydables |

| Corps d’outil: | TPM16R100M31.7-06 (ø100, z = 6) |

| Plaquette: | LMMU160908PNER-MJ |

| Nuance: | AH725 |

| Conditions de coupe: | Vc = 100 (m/min) fz = 0.3 (mm/t) Vf = – (mm/min) ap = 10 (mm) ae = 40 (mm) Application: fraisage 90° Liquide de refroidissement : à sec Machine: Vertical M/C, BT50 |

Conditions de coupe recommandées

Bore, shank type

| ISO | Workpiece materials | Hardness | Priority | Grades | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|

Low carbon steel S15C, SS400, etc. C15E4, E275A, etc. |

– 200 HB | First choice | AH3225 | 100 – 300 | 0.05 – 0.3 | |

| – 200 HB | Wear resistance | T3225 | 150 – 350 | 0.05 – 0.2 | |||

| – 200 HB | Fracture resistance | AH3135 | 100 – 250 | 0.05 – 0.3 | |||

| Carbon steel and alloy steel S55C, SCM440, etc. C55,42CrMo4, etc. |

– 300 HB | First choice | AH3225 | 100 – 250 | 0.05 – 0.25 | ||

| – 300 HB | Wear resistance | T3225 | 150 – 350 | 0.05 – 0.2 | |||

| – 300 HB | Fracture resistance | AH3135 | 100 – 230 | 0.05 – 0.25 | |||

| Prehardend steel NAK80, etc. PX5, etc. |

30 – 40 HRC | First choice | AH3225 | 100 – 230 | 0.05 – 0.25 | ||

| 30 – 40 HRC | Wear resistance | T3225 | 120 – 350 | 0.05 – 0.2 | |||

| 30 – 40 HRC | Fracture resistance | AH3135 | 100 – 230 | 0.05 – 0.25 | |||

|

Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | First choice | AH3135 | 90 – 180 | 0.05 – 0.25 | |

|

Grey cast iron FC250, etc. 250, etc. |

150 – 250 HB | First choice | AH8015 | 100 – 300 | 0.05 – 0.3 | |

| 150 – 250 HB | Wear resistance | T1215 | 120 – 350 | 0.05 – 0.2 | |||

| Ductile cast iron FCD400, FCD600, etc. 600-3, etc. |

150 – 250 HB | First choice | AH8015 | 100 – 200 | 0.05 – 0.3 | ||

| 150 – 250 HB | Wear resistance | T1215 | 120 – 350 | 0.05 – 0.2 | |||

|

Titanium alloys Ti-6AI-4V, etc. |

– | First choice | AH3135 | 30 – 60 | 0.05 – 0.2 | |

| Superalloys Inconel718, etc. |

– | First choice | AH8015 | 20 – 50 | 0.05 – 0.1 | ||

|

Hardened steel | SKD61 / X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | AH8015 | 45 – 70 | 0.05 – 0.15 |

| SKD11 / X153CrMoV12, etc. |

50 – 60 HRC | First choice | AH8015 | 40 – 65 | 0.05 – 0.1 | ||

Roughing type

| ISO | Workpiece materials | Hardness | Priority | Grades | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|

Low carbon steel S15C, SS400, etc. C15E4, E275A, etc. |

– 200 HB | First choice | AH3225 | 100 – 300 | 0.05 – 0.25 | |

| – 200 HB | Wear resistance | T3225 | 150 – 350 | 0.05 – 0.2 | |||

| – 200 HB | Fracture resistance | AH3135 | 100 – 250 | 0.05 – 0.25 | |||

| Carbon steel and alloy steel S55C, SCM440, etc. C55,42CrMo4, etc. |

– 300 HB | First choice | AH3225 | 100 – 250 | 0.05 – 0.2 | ||

| – 300 HB | Wear resistance | T3225 | 150 – 350 | 0.05 – 0.2 | |||

| – 300 HB | Fracture resistance | AH3135 | 100 – 230 | 0.05 – 0.25 | |||

| Prehardend steel NAK80, etc. PX5, etc. |

30 – 40 HRC | First choice | AH3225 | 100 – 230 | 0.05 – 0.2 | ||

| 30 – 40 HRC | Wear resistance | T3225 | 120 – 350 | 0.05 – 0.2 | |||

| 30 – 40 HRC | Fracture resistance | AH3135 | 100 – 230 | 0.05 – 0.25 | |||

|

Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | First choice | AH3135 | 90 – 180 | 0.05 – 0.25 | |

|

Grey cast iron FC250, etc. 250, etc. |

150 – 250 HB | First choice | AH8015 | 100 – 300 | 0.05 – 0.25 | |

| 150 – 250 HB | Wear resistance | T1215 | 120 – 350 | 0.05 – 0.25 | |||

| Ductile cast iron FCD400, FCD600, etc. 600-3, etc. |

150 – 250 HB | First choice | AH8015 | 100 – 200 | 0.05 – 0.25 | ||

| 150 – 250 HB | Wear resistance | T1215 | 120 – 350 | 0.05 – 0.25 | |||

|

Titanium alloys Ti-6AI-4V, etc. |

– | First choice | AH3135 | 30 – 60 | 0.05 – 0.15 | |

| Superalloys Inconel718, etc. |

– | First choice | AH8015 | 20 – 50 | 0.05 – 0.1 | ||

|

Hardened steel | SKD61 / X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | AH8015 | 30 – 60 | 0.05 – 0.15 |

| SKD11 / X153CrMoV12, etc. |

50 – 60 HRC | First choice | AH8015 | 25 – 55 | 0.05 – 0.1 | ||

RETOUR