Applications & Fonctionnalités

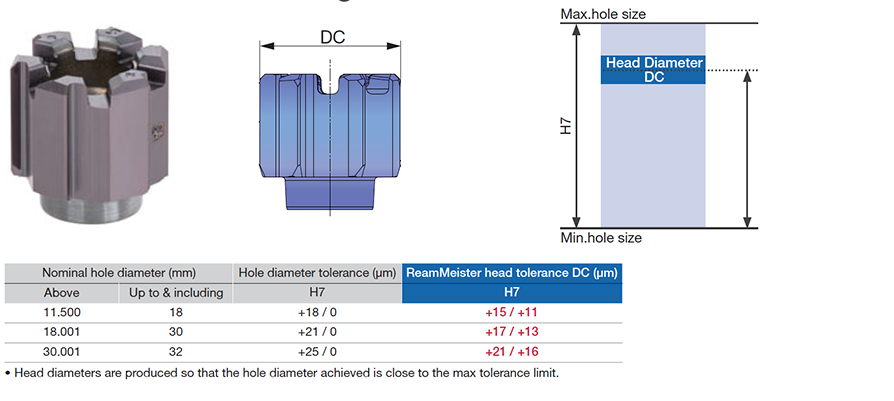

Applications

Fonctionnalités

1. Embout d’alésage de haute précision pour les applications de la gamme de tolérance de trou H7

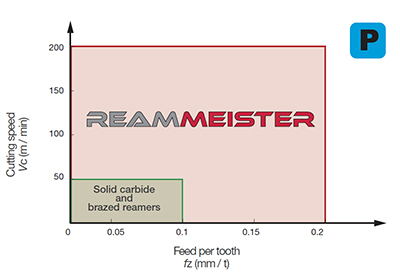

2. Permet d’appliquer des vitesses de coupe et des avances plus élevées que les alésoirs en carbure monobloc ou brasés qui garantissent ainsi une productivité élevée

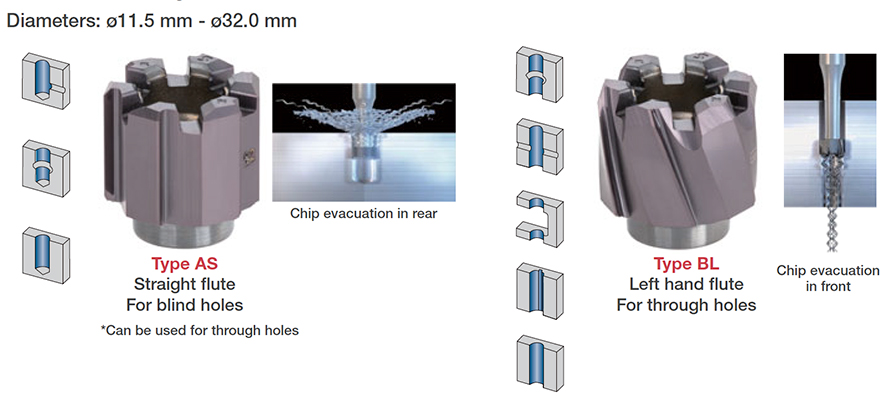

3. 2 types d’embouts d’alésage sont disponibles en fonction des types de trous

Plaquettes & Nuances

Plaquette

HRM-BL (ø10 – ø32 mm)

- Reaming heads with left hand flute for through holes

HRM-AS (ø10 – ø32 mm)

- Reaming heads with straight flute for blind holes

Nuances

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Bel équilibre entre la résistance à l’usure et à l’écaillage

- Convient à l’usinage des aciers et des aciers inoxydables dans des conditions de coupe générales

Corps d'alésoir

Exemples pratiques

Exemple #1

Industrie automobile

| Partie: | Etrier de bride |

| Matériau: | FCD500 / GGG50 / 450-10S |

| Alésoir: | TRM-T9-R32-5 |

| Plaquette: | HRM-27.000-BL-T9 |

| Nuance: | AH725 |

| Conditions de coupe: | Vc = 100 (m/min) f = 1.2 (mm/rev) Vf = 1415 (mm/min) H = 20 (mm) Liquide de refroidissement : interne Machine: Horizontal M/C |

Exemple #2

Industrie automobile

| Partie: | Etrier de bride |

| Matériau: | S45C / C45 |

| Foret: | TRM-T9-R32-5 |

| Plaquette: | HRM-27.000-BL-T9 |

| Nuance: | AH725 |

| Conditions de coupe: | Vc = 90 (m/min) f = 0.8 (mm/rev) Vf = 850 (mm/min) H = 15 (mm) Liquide de refroidissement : interne Machine: Horizontal M/C |

Conditions de coupe recommandées

Conversion table for feed per tooth

| ISO | Workpiece materials | Cutting speed Vc (m/min) | Feed:fz (mm/t) | |||

|---|---|---|---|---|---|---|

| AS: Straight flute(for blind holes) | BL: Left hand flute(for through holes) | |||||

| ø10 – ø16 | ø16 – ø32 | ø10 – ø16 | ø16 – ø32 | |||

|

Low carbon steel (C<0.3) SS400, SM490, S25C, E275A, etc. |

80 – 200 | 0.05 – 0.18 | 0.05 – 0.20 | 0.05 – 0.20 | 0.05 – 0.27 |

| Carbon steel (C>0.3) S45C, S55C, C45, C55, etc. |

80 – 150 | 0.05 – 0.15 | 0.05 – 0.18 | 0.05 – 0.18 | 0.05 – 0.25 | |

| Low carbon steel (C<0.3) SCM415, etc. |

80 – 200 | 0.05 – 0.18 | 0.05 – 0.20 | 0.05 – 0.20 | 0.05 – 0.27 | |

| Alloy steel (C>0.3) SCM440, SCr420, 42CrMo4, 20Cr4 etc. |

50 – 150 | 0.03 – 0.10 | 0.05 – 0.13 | 0.05 – 0.13 | 0.05 – 0.17 | |

|

Stainless steel(Austenitic) SUS304, SUS316, X5CrNi18-9, X5CrNiMo17-12-3, etc. |

20 – 40 | 0.03 – 0.10 | 0.03 – 0.13 | 0.05 – 0.13 | 0.05 – 0.17 |

| Stainless steel(Martensitic and ferritic) SUS430, SUS416, X6Cr17, etc. |

20 – 40 | 0.03 – 0.10 | 0.03 – 0.13 | 0.05 – 0.13 | 0.05 – 0.17 | |

| Stainless steel(Precipitation hardening) SUS630, X5CrNiCuNb16-4 etc. |

20 – 40 | 0.03 – 0.10 | 0.03 – 0.13 | 0.05 – 0.13 | 0.05 – 0.17 | |

|

Grey cast iron FC250, GG25, 250 etc. |

100 – 250 | 0.05 – 0.18 | 0.05 – 0.20 | 0.05 – 0.20 | 0.05 – 0.27 |

| Ductile cast iron FCD700, etc. |

80 – 200 | 0.05 – 0.15 | 0.05 – 0.18 | 0.05 – 0.18 | 0.05 – 0.25 | |

|

Aluminum alloy | 100 – 300 | 0.05 – 0.18 | 0.05 – 0.20 | 0.05 – 0.20 | 0.05 – 0.27 |

|

High temp. alloy Inconel718 etc. |

15 – 50 | 0.03 – 0.06 | 0.03 – 0.08 | 0.05 – 0.1 | 0.05 – 0.13 |

| Titanium alloy Ti-6Al-4V etc. |

30 – 60 | 0.03 – 0.10 | 0.03 – 0.13 | 0.05 – 0.13 | 0.05 – 0.17 | |

|

Hardened steel Over 40HRC etc. |

50 – 100 | 0.03 – 0.08 | 0.03 – 0.1 | 0.05 – 0.12 | 0.05 – 0.15 |

Conversion table for feed per revolution

| ISO | Workpiece materials | Cutting speed Vc (m/min) | Feed:f (mm/rev) | |||||

|---|---|---|---|---|---|---|---|---|

| AS: Straight flute(for blind holes) | BL: Left hand flute(for through holes) | |||||||

| ø10 – ø16 6 flutes |

ø16.001 – ø20 6 flutes |

ø20.001 – ø32 8 flutes |

ø10 – ø16 6 flutes |

ø16.001 – ø20 6 flutes |

ø20.001 – ø32 8 flutes |

|||

|

Low carbon steel (C<0.3) SS400, SM490, S25C, E275A, etc. |

80 – 200 | 0.3 – 1.08 | 0.3 – 1.2 | 0.4 – 1.6 | 0.3 – 1.2 | 0.3 – 1.62 | 0.4 – 2.16 |

| Carbon steel (C>0.3) S45C, S55C, C45, C55, etc. |

80 – 150 | 0.3 – 0.9 | 0.3 – 1.08 | 0.4 – 1.44 | 0.3 – 1.08 | 0.3 – 1.5 | 0.4 – 2 | |

| Low carbon steel (C<0.3) SCM415, etc. |

80 – 200 | 0.3 – 1.08 | 0.3 – 1.2 | 0.4 – 1.6 | 0.3 – 1.2 | 0.3 – 1.2 | 0.4 – 2.16 | |

| Alloy steel (C>0.3) SCM440, SCr420, 42CrMo4, 20Cr4 etc. |

50 – 150 | 0.18 – 0.6 | 0.3 – 0.78 | 0.4 – 1.04 | 0.3 – 0.78 | 0.3 – 1.02 | 0.4 – 1.36 | |

|

Stainless steel(Austenitic) SUS304, SUS316, X5CrNi18-9, X5CrNiMo17-12-3, etc. |

20 – 40 | 0.18 – 0.6 | 0.18 – 0.78 | 0.24 – 1.04 | 0.3 – 0.78 | 0.3 – 1.02 | 0.4 – 1.36 |

| Stainless steel(Martensitic and ferritic) SUS430, SUS416, X6Cr17, etc. |

20 – 40 | 0.18 – 0.6 | 0.18 – 0.78 | 0.24 – 1.04 | 0.3 – 0.78 | 0.3 – 1.02 | 0.4 – 1.36 | |

| Stainless steel(Precipitation hardening) SUS630, X5CrNiCuNb16-4 etc. |

20 – 40 | 0.18 – 0.6 | 0.18 – 0.78 | 0.24 – 1.04 | 0.3 – 0.78 | 0.3 – 1.02 | 0.4 – 1.36 | |

|

Grey cast iron FC250, GG25, 250 etc. |

100 – 250 | 0.3 – 1.08 | 0.3 – 1.2 | 0.4 – 1.6 | 0.3 – 1.2 | 0.3 – 1.62 | 0.4 – 2.16 |

| Ductile cast iron FCD700, etc. |

80 – 200 | 0.3 – 0.9 | 0.3 – 1.08 | 0.4 – 1.44 | 0.3 – 1.8 | 0.3 – 1.62 | 0.4 – 2 | |

|

Aluminum alloy | 100 – 300 | 0.3 – 1.08 | 0.3 – 1.2 | 0.4 – 1.6 | 0.3 – 1.2 | 0.3 – 1.62 | 0.4 – 2.16 |

|

High temp. alloy Inconel718 etc. |

15 – 50 | 0.18 – 0.36 | 0.18 – 0.48 | 0.24 – 0.64 | 0.3 – 0.6 | 0.3 – 0.78 | 0.4 – 1.04 |

| Titanium alloy Ti-6Al-4V etc. |

30 – 60 | 0.18 – 0.6 | 0.18 – 0.78 | 0.24 – 1.04 | 0.3 – 0.78 | 0.3 – 1.02 | 0.4 – 1.36 | |

|

Hardened steel Over 40HRC etc. |

50 – 100 | 0.18 – 0.48 | 0.18 – 0.6 | 0.24 – 0.8 | 0.3 – 0.72 | 0.3 – 0.9 | 0.4 – 1.2 |

Pour plus d’informations sur ce produit, visitez notre e-catalogue en ligne ou téléchargez le rapport sur le produit :