Applications & Fonctionnalités

Applications

Fonctionnalités

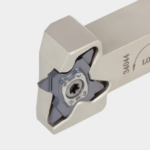

1. Système de serrage unique en 3 points

La conception unique de la poche offre une répétabilité d’indexation précise de la hauteur de l’arête de coupe

2. Brise-copeaux rectifiés ou moulés

Gamme améliorée pour une plus grande flexibilité

3. Service de livraison accéléré pour les plaquettes de rainurage spéciaux

Plaquettes & Nuances

Plaquettes

Plaquettes de rainurage et de tronçonnage TetraMini-Cut (largeur de rainurage 0.33 – 3.0 mm)

- Outils de rainurage rigides avec des plaquettes à 4 arêtes de coupe

Plaquettes de rainurage et de tronçonnage TetraForce-Cut (largeur de rainurage 0.5 – 4.0 mm)

- Outils de rainurage rigides avec plaquettes à 4 arêtes de coupe

Plaquettes de filetage TetraMini-Cut (pas de 0.4 – 3.0 mm)

- Outils de filetage rigides avec plaquettes à 4 arêtes de coupe

Nuances

SH7025

![]()

![]()

![]()

![]()

- P20 – P30 / M20 – M30

- The latest grade with sharp cutting edge designed for small part machining

- A combination of a columnar-structured TiCN coating and multilayered TiAlN coating provides superior surface quality and process security

AH7025

![]()

![]()

![]()

- P20 – P30 / M20 – M30 / S15 – S25

- Excellente résistance à l’usure et grande rigidité

- Premier choix pour le rainurage de divers matériaux

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Bel équilibre entre résistance à l’usure et à l’écaillage

- Convient pour l’usinage des aciers et des aciers inoxydables dans des conditions de coupe générales

SH725

![]()

![]()

![]()

![]()

![]()

![]()

- P20 – P30 / M20 – M30

- Haute résistance à l’usure

- Conçu pour l’usinage des aciers et de l’inox

AH8015

![]()

![]()

![]()

![]()

![]()

- M01 – M20 / S10 – S20

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

AH8005

![]()

![]()

![]()

- M01 – M10 / S01 – S10 / H10 – H20

- Good resistance to wear and adhesion

- Excellent performance in machining heat-resistant alloy at high speed

AH6235

![]()

![]()

- P30 – P40 / M30 – M40

- Provides high reliability in interrupted cutting with large depths of cut

NS9530

![]()

![]()

- P20 – P30 / M20 – M30 / K10 – K20

- High fracture resistance

- Suitable for finishing to medium cutting of steel

TH10

![]()

![]()

![]()

![]()

Porte-outils

Rainurage & Tronçonnage

Porte-outils TetraMini-Cut

Outils de rainurage et de filetage rigides avec plaquettes 4 arêtes de coupe

Rainurage & Tronçonnage

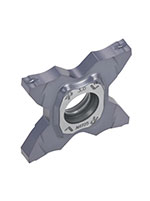

Porte-outils TetraForce-Cut

Outils de rainurage et de filetage rigides avec plaquettes à 4 arêtes de coupe

Autre

Queue TetraForce-Cut / TetraMini-Cut

Outils de rainurage et de filetage rigides avec plaquettes à 4 arêtes de coupe

Exemples pratiques

Exemple #1

Ingénierie générale

| Partie: | Stator arbre |

| Matériau | S45C / C45 |

| Porte-outils: | STCR2525-27 |

| Plaquette: | TCS27-200-020 |

| Nuance: | AH725 |

| Conditions de coupe: | Vc = 210 (m/min) f = 0.15 (mm/rev) CDX = 2 (mm) CW = 2 (mm) Application: rainurage externe Liquide de refroidissement : avec Machine: tour CN |

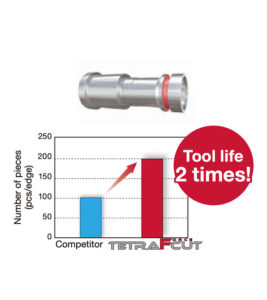

Exemple #2

Industrie automobile

| Partie: | Arbre d’entrée |

| Matériau: | SCr420 / 20Cr4 |

| Porte-outils: | STCR2525Z18 |

| Plaquette: | TCG18R150-020 |

| Nuance: | AH7025 |

| Conditions de coupe: | Vc = 100 (m/min) f = 0.08 (mm/rev) CDX = 2.1 (mm) CW = 2 (mm) Application: rainurage externe Liquide de refroidissement : avec Machine: tour CN |

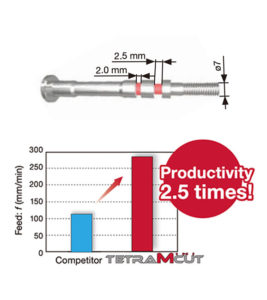

Exemple #3

Industrie miniature et électronique

| Partie: | Arbre de bobine |

| Matériau: | S45C / C45 |

| Porte-outils: | STCR1010X18 |

| Plaquette: | TCP18R200F-010 |

| Nuance: | SH725 |

| Conditions de coupe: | Vc = 43 (m/min) f = 0.10 (mm/rev) CDX= 1.5 / 1.1 (mm/min) CW = 2 / 2.5 (mm) Application: rainurage externe Liquide de refroidissement : avec Machine: tour suisse |

Conditions de coupe recommandées

TCL18R/L, TCS18R/L (3D chipbreaker), TCG18R/L (honed edge), TCG18R/L (Full R)

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | ||

|---|---|---|---|---|---|---|

| TCL18 | TCS18 | TCG18 | ||||

| Carbon steel S45C / C45, etc. |

AH8005 | 100 – 300 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 100 – 200 | |||||

| AH6235 | 80 – 120 | |||||

| NS9530 | 120 – 250 | |||||

| Alloy steel SCM435 / 34CrMo4, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 50 – 180 | |||||

| AH6235 | 50 – 100 | |||||

| NS9530 | 100 – 200 | |||||

| Stainless steel SUS304 / X5CrNi18-9, etc. |

AH8005 | 100 – 150 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 80 – 120 | |||||

| AH6235 | 50 – 120 | |||||

| Grey cast iron FC250 / 250, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 50 – 180 | |||||

| AH6235 | 50 – 100 | |||||

| NS9530 | 50 – 180 | |||||

| Ductile cast iron FCD400 / 400-15, etc. |

AH8005 | 80 – 180 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 50 – 120 | |||||

| AH6235 | 50 – 80 | |||||

| NS9530 | 50 – 180 | |||||

| Titanium alloys Ti-6Al-4V, etc. |

AH8005 | 50 – 70 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 30 – 60 | |||||

| Superalloys Inconel718, etc. |

AH8005 | 40 – 60 | 0.03 – 0.12 | 0.04 – 0.16 | 0.04 – 0.14 | |

| AH7025 | 20 – 50 | |||||

TCP18R/L (lightly honed edge) / TCP18R/L-F (sharp edge)

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

| Carbon steel S45C / C45, etc. |

SH7025 | 80 – 180 | 0.01 – 0.08 | |

| AH725 | 80 – 180 | 0.03 – 0.1 | ||

| Alloy steel SCM435 / 34CrMo4, etc. |

SH7025 | 80 – 180 | 0.01 – 0.08 | |

| AH725 | 80 – 180 | 0.03 – 0.1 | ||

| Stainless steel SUS304 / X5CrNi18-9, etc. |

SH7025 | 50 – 120 | 0.01 – 0.08 | |

| AH725 | 50 – 120 | 0.03 – 0.1 | ||

| Grey cast iron FC250 / 250, etc. |

AH725 | 50 – 180 | 0.03 – 0.1 | |

| SH7025 | 50 – 180 | 0.01 – 0.08 | ||

| Ductile cast iron FCD400 / 400-15, etc. |

AH725 | 50 – 180 | 0.03 – 0.1 | |

| SH7025 | 50 – 180 | 0.01 – 0.08 | ||

| Titanium alloys Ti-6Al-4V, etc. |

SH7025 | 30 – 80 | 0.01 – 0.08 | |

| AH725 | 30 – 80 | 0.03 – 0.1 | ||

| Superalloys Inconel718, etc. |

SH7025 | 20 – 60 | 0.01 – 0.08 | |

| AH725 | 20 – 60 | 0.03 – 0.1 |

TCF18L (Face grooving)

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

| Carbon steel S45C / C45, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Alloy steel SCM435 / 34CrMo4, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Stainless steel SUS304 / X5CrNi18-9, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Grey cast iron FC250 / 250, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Ductile cast iron FCD400 / 400-15, etc. |

SH7025 | 30 – 100 | 0.01 – 0.04 | |

| Titanium alloys Ti-6Al-4V, etc. |

SH7025 | 20 – 40 | 0.01 – 0.04 | |

| Superalloys Inconel718, etc. |

SH7025 | 10 – 30 | 0.01 – 0.04 |

TCT18R/L / TCT18FR

| ISO | Workpiece material | Hardness | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|

| Steel / Alloy steel S45C, SCM440, etc. C45, 42CrMoS4, etc. |

< 200HB | AH8015 | 80 – 180 | |

| AH725 | 60 – 150 | |||

| SH7025 | 60 – 150 | |||

| > 200HB | AH8015 | 60 – 160 | ||

| AH725 | 60 – 150 | |||

| SH7025 | 60 – 150 | |||

| Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– | AH8015 | 50 – 130 | |

| – | AH725 | 50 – 80 | ||

| – | SH7025 | 50 – 80 | ||

| Cast iron FC250, FC300, etc. 250, 300, etc. |

– | AH8015 | 60 – 150 | |

| – | AH725 | 50 – 100 | ||

| – | SH7025 | 50 – 100 | ||

| Superalloys Ti-6AI-4V, Inconel718, etc. |

– | AH8015 | 20 – 80 | |

| – | AH725 | 20 – 80 | ||

| – | SH7025 | 20 – 80 |

TCL27, TCS27, TCM27, TCG27, TCL38

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | Depth of cut for profiling (with full radius insert) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grooving, Parting off |

Parting off (with hand) |

Profiling (with full radius insert) |

|||||||||

| TCL | TCS | TCM | TCG | TCS | TCS | TCM | |||||

| Carbon steel S45C / C45, etc. |

AH8005 | 100 – 300 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.25 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 100 – 200 | ||||||||||

| AH6235 | 80 – 120 | ||||||||||

| NS9530 | 120 – 250 | ||||||||||

| Alloy steel SCM435 / 34CrMo4, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.25 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 50 – 180 | ||||||||||

| AH6235 | 50 – 100 | ||||||||||

| NS9530 | 100 – 200 | ||||||||||

| Stainless steel SUS304 / X5CrNi18-9, etc. |

AH8005 | 100 – 150 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.2 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 80 – 120 | ||||||||||

| AH6235 | 50 – 120 | ||||||||||

| Grey cast iron FC250 / 250, etc. |

AH8005 | 80 – 250 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.25 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 50 – 180 | ||||||||||

| AH6235 | 50 – 100 | ||||||||||

| NS9530 | 50 – 180 | ||||||||||

| Ductile cast iron FCD400 / 400-15, etc. |

AH8005 | 80 – 180 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.2 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.15 | 0.5 | |

| AH7025 | 50 – 120 | ||||||||||

| AH6235 | 50 – 80 | ||||||||||

| NS9530 | 50 – 180 | ||||||||||

| Titanium alloys Ti-6Al-4V, etc. |

AH8005 | 50 – 70 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.15 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.1 | 0.5 | |

| AH7025 | 30 – 60 | ||||||||||

| Superalloys Inconel718, etc. |

AH8005 | 40 – 60 | 0.03 – 0.12 | 0.05 – 0.15 | 0.05 – 0.15 | 0.03 – 0.1 | 0.04 – 0.12 | 0.05 – 0.1 | 0.05 – 0.1 | 0.5 | |

| AH7025 | 20 – 50 | ||||||||||

1QP-TCX18R/L (Widening external grooves)

| ISO | Workpiece materials | Hardness | Grades | Cutting speed Vc (m/min) |

Feed: f (mm/rev) | Depth of cut: ae (mm) | ||

|---|---|---|---|---|---|---|---|---|

| RE = 0.1 | RE = 0.2 | RE = 0.1 | RE = 0.2 | |||||

| Hard material · Hardened steel SCM435 / 34CrMo4, SUJ2 / B1 etc. |

> 50 HRC | BX360 | 80 – 150 | 0.02 – 0.05 | 0.03 – 0.1 | 0.15 – 0.3 | 0.15 – 0.5 | |

RETOUR