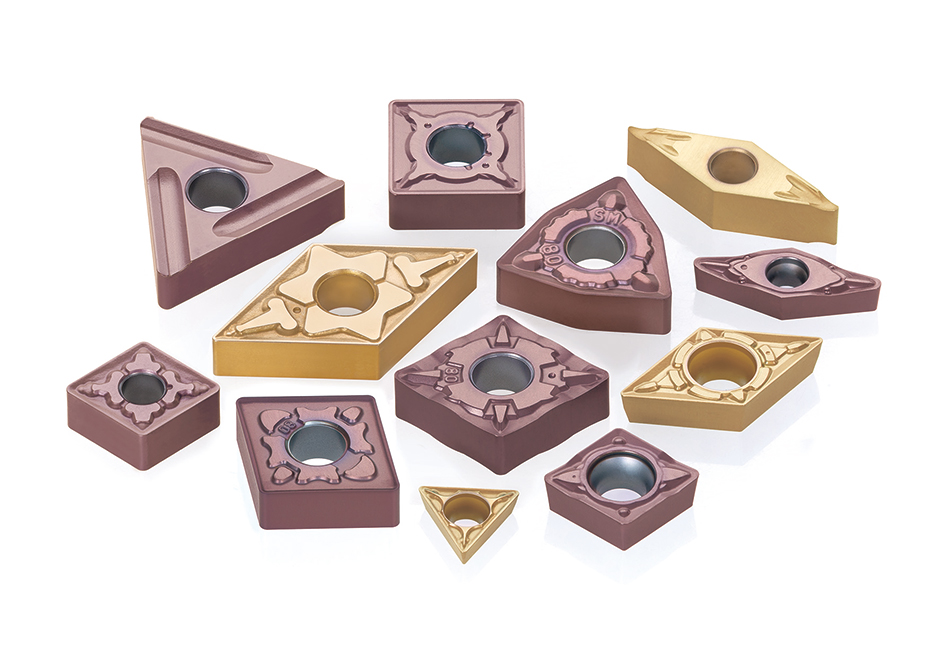

Iwaki, November 2021 — Tungaloy has unveiled new stainless steel turning insert grades T6215 and AH6235.

New T6215 is a CVD coated grade optimized for high speed turning applications of stainless steel, while AH6235 PVD grade showcases exceptional reliability during interrupted cuts or heavy-duty rough turning requiring a large depth of cut. These additions complement the existing AH6225, a proven, first choice insert grade for stainless steel turning.

T6215 consists of a thick CVD coating that is 1.3 times as thick as conventional grades, demonstrating superior wear resistance. The outer layer of the coating features an extremely hard surface that effectively reduces flank wear, enhancing the grade’s tool life performance in high speed continuous cuts.

AH6235 incorporates a thick titanium-rich PVD coating with high thermal resistance. This coating is extremely effective for decreasing crater wear, a typical wear mode during rough machining of stainless steel. A tough dedicated carbide substrate improves the grade’s fracture resistance, exhibiting exceptional reliability during interrupted cuts or heavy-duty roughing operations.

In addition, newly developed SDM-style chipbreaker reduces notch wear, which is another common wear mechanism during stainless steel machining, further providing reliability across a spectrum of applications.

The new T6215 and AH6235 insert grades complement the existing AH6225 general purpose grade, provide long tool life and process security for a wide range of stainless steel turning applications.

Product information

Main product report_No. 547-G