Iwaki, Japan – January, 2026– Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its PVD grade AH8015 application to four milling tool series—DoForceTri, MillQuadFeed, TungTriShred, and DuQuadMill—enhancing wear resistance and tool life across diverse machining operations.

Challenges and Trends

In a wide range of industries such as automotive, construction machinery, aerospace, and mold manufacturing, the demand for greater production efficiency and cost reduction is stronger than ever. In particular, when machining difficult-to-cut materials such as cast iron, heat-resistant alloys, and hardened steels, frequent tool replacement due to wear becomes a major obstacle to improving productivity.

Under these market conditions, the need for highly wear-resistant tools that can deliver longer tool life and stable machining performance is rapidly increasing. To address this challenge, Tungaloy has expanded the PVD grade AH8015 to four milling tool lines, providing high reliability and cost performance in difficult-to-cut material machining. |

Product Overview

DoForce-Tri

Application: Cutter for shoulder milling and face milling.

Features:

- Uses double-sided inserts with six cutting corners to reduce cost and improve productivity.

- Capable of a wide range of machining such as shoulder milling and slotting.

- Curved cutting edge design reduces cutting resistance while maintaining good chip evacuation.

👉 A tool suitable for applications where improving the efficiency and economy of shoulder milling is desired.

TungTriShred

Application: High-productivity roughing cutter for shoulder milling and slotting.

Features:

- Serrated cutting edges split chips to suppress chatter.

- Two types of inserts can be used on the same cutter body.

- Delivers stable high-efficiency rough machining even with long overhangs.

👉 Ideal for situations where you want to suppress chatter and increase rough machining efficiency.

DoQuadMill

Application: Face milling cutter for general face milling, including near walls and corners.

Features:

- Uses 8-corner inserts with a focus on economy and accessibility.

- Supports rough to finish face milling while avoiding interference.

- Low resistance and low cutting forces make it strong even with unstable workpieces.

👉 A tool suitable for face milling and corner cutting where accessibility is required.

MillQuadFeed

Application: Milling cutter for high-feed machining.

Features:

- Two types of inserts with different entry angles can be mounted on the same body.

- High rigidity and low resistance design enables high-efficiency machining and long tool life.

- Supports a wide range of applications including shoulder milling and plunging.

👉 A versatile cutter that enables high-feed machining tailored to different applications by changing the entry angle.

Benefits and Features

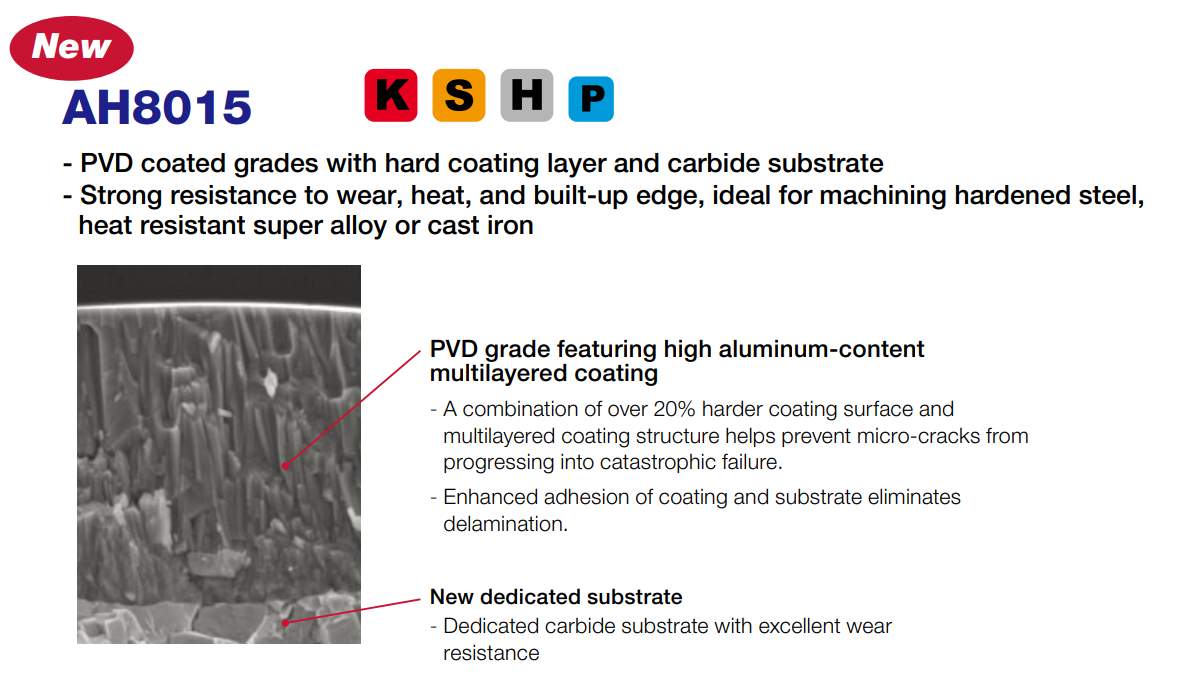

Feature 1: Excellent Wear Resistance with High-Hardness PVD Coating

- The high-aluminum-content PVD coating forms a hard and dense film.

- Suppresses wear progression even during long cutting operations, maintaining stable machining accuracy.

- Achieves extended tool life especially in the machining of difficult-to-cut materials such as cast iron, heat-resistant alloys, and hardened steels.

Feature 2: Adaptability to a Wide Range of Machining Conditions

- The lineup has been expanded with the addition of grade AH8015 to complement existing grades.

- Enables optimal grade selection according to the work material and machining conditions.

- Covers a wide range of needs—from high-efficiency cutting to high-precision finishing.

Feature 3: Improved Productivity and Cost Efficiency

- Extended tool life reduces tool change frequency.

- Stable machining quality helps lower defect rates and shorten setup time.

- As a result, contributes to the overall reduction of production costs.