Iwaki, Japon – Septembre 2025 – Tungaloy Corporation (Président : Satoshi Kinoshita, Siège social : Iwaki City, Préfecture de Fukushima) annonce l’extension de sa gamme de plaquettes CBN avec le lancement de la nouvelle nuance « BX4015 », conçue pour l’usinage à haute efficacité des alliages frittés, offrant une résistance exceptionnelle à l’usure et une stabilité de durée de vie sur une large variété de formes de plaquettes ISO.

Enjeux et Tendances

Dans la production de masse de composants en métallurgie des poudres (PM) pour les groupes motopropulseurs et l’électrification automobile, les écaillages et ruptures dus aux coupes interrompues sont fréquents. Ces problèmes entraînent des variations de durée de vie des outils et une dégradation de l’état de surface. De plus, les variations de caractéristiques entre lots de matériaux frittés compliquent l’optimisation des conditions de coupe, impactant négativement l’efficacité et les coûts de production. Sur le terrain, une forte demande existe pour des coupes à faible résistance grâce à des arêtes de coupe vives, tout en conservant la ténacité et la résistance à l’usure pour prévenir l’écaillage. Il est crucial de garantir une durée de vie élevée de l’outil et une performance d’usinage stable, tout en maximisant la rentabilité.

Présentation du produit

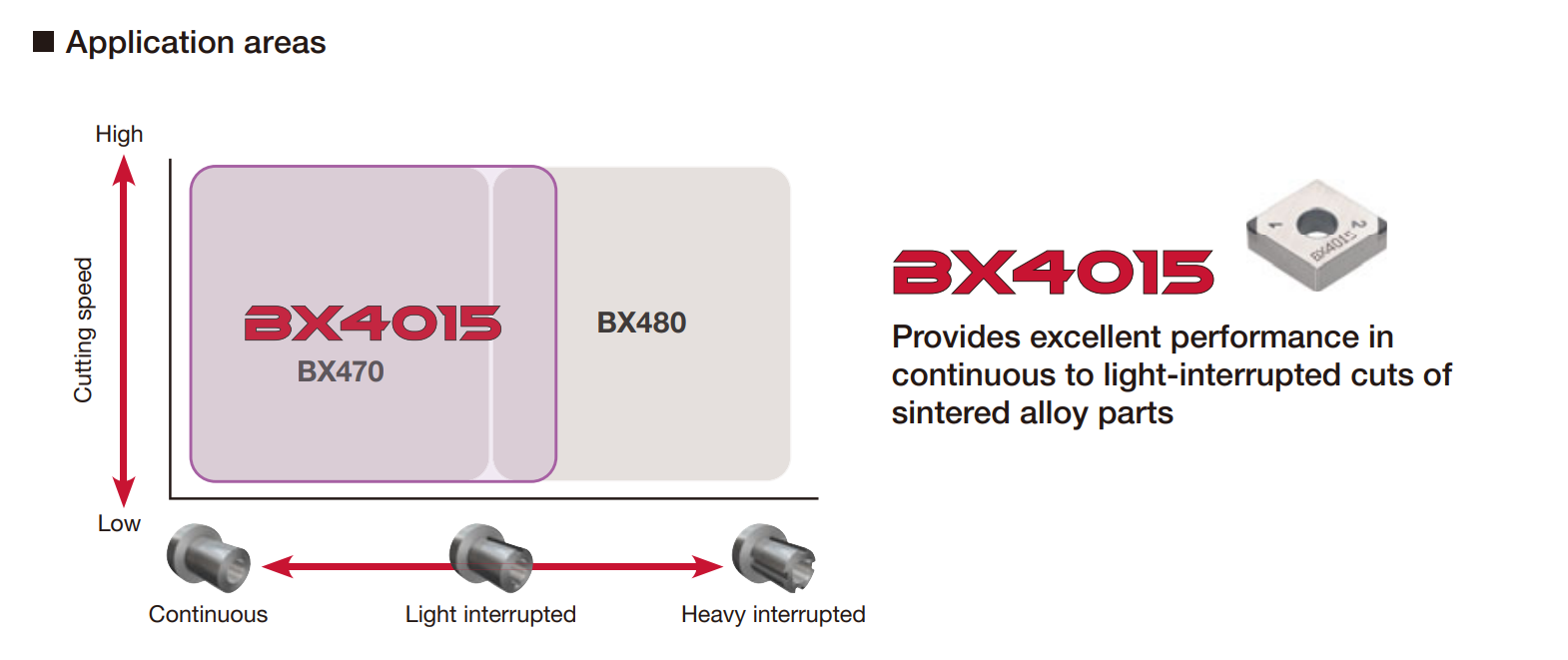

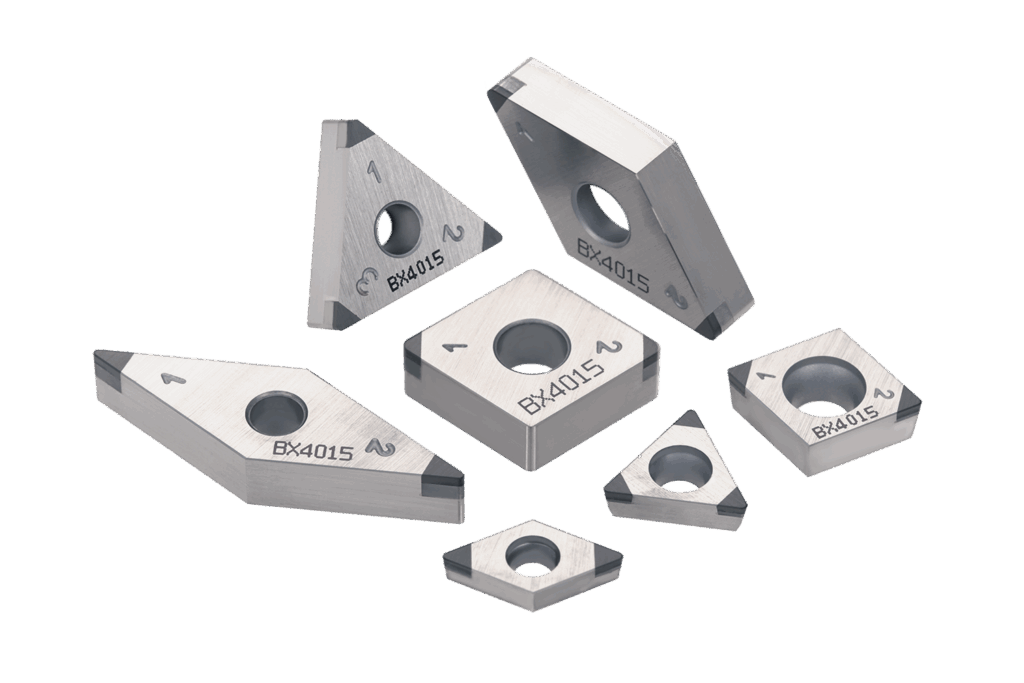

BX4015 est une nuance CBN dédiée à l’usinage des alliages frittés. Adaptée aux opérations de finition et de coupe légère, elle assure une suppression stable des bavures et un excellent état de surface. Facile d’utilisation en coupe continue ou interrompue sur diamètres extérieurs et faces, elle convient aussi aux applications à arête vive. Grâce à une grande variété de géométries de plaquettes, BX4015 favorise une production de masse stable.

Avantages et Caractéristiques

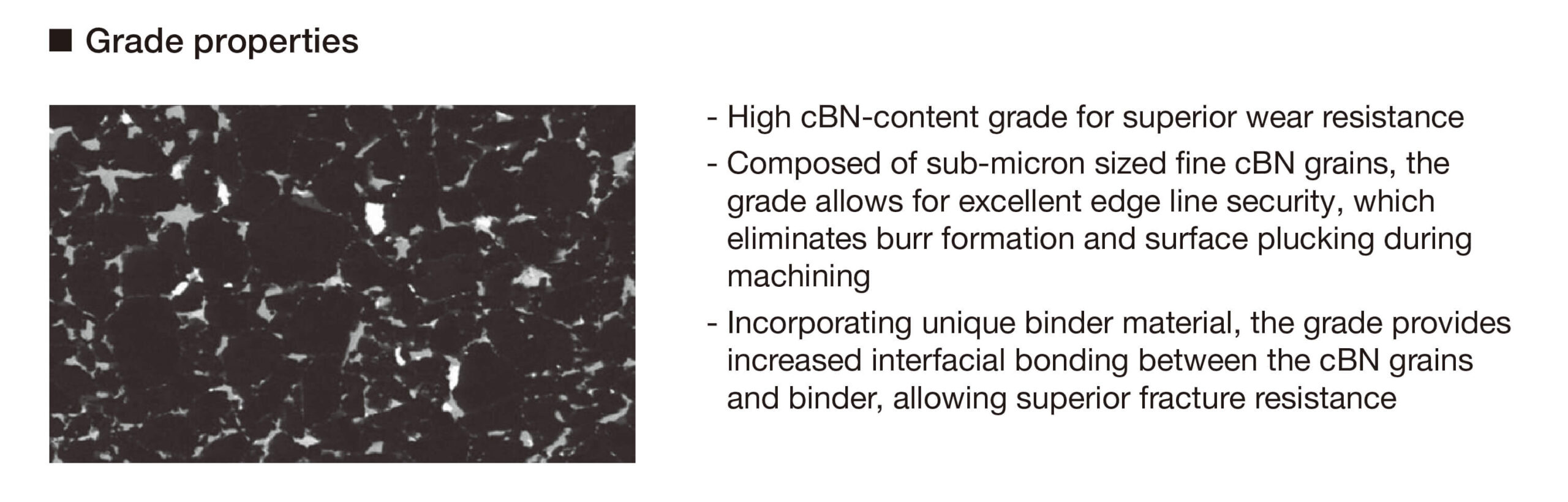

Caractéristique 1 : Haute résistance à l’usure grâce à une teneur élevée en CBN

- Ralentit l’usure grâce à un liant haute dureté

- Prolonge la durée de vie même en coupe continue longue ou sur matériaux à haute dureté

- Assure des performances stables même sur les matériaux difficiles comme les alliages frittés

Caractéristique 2 : Haute résistance à la rupture grâce à un liant spécial

- Liant spécial renforçant l’adhérence entre particules de CBN et matrice

- Réduit les écaillages et ruptures soudaines, augmentant la fiabilité

- Maintient une coupe stable sous fortes charges, minimisant les incidents

Caractéristique 3 : Arête de coupe renforcée et meilleure finition grâce aux particules fines de CBN

- Particules fines de CBN pour une arête plus vive et plus stable

- Réduction des bavures et écaillages, pour une meilleure qualité de surface

- Coupe fluide et précise, même en finition

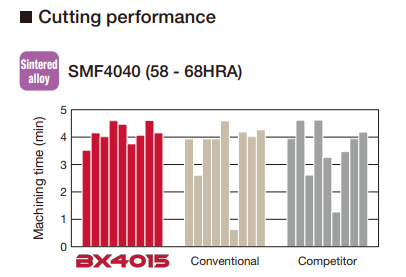

Cas d’application

DURÉE DE VIE PROLONGÉE

BX4015 a démontré une excellente résistance à l’écaillage, un bon état de surface et une durée de vie multipliée par 1,5.