Iwaki, Japón – Febrero, 2025 – Tungaloy Corporation (Presidente: Satoshi Kinoshita, Oficina central: Ciudad de Iwaki, Prefectura de Fukushima) anuncia la ampliación de su serie TungMeister, con una gama más amplia de fresas de mango de cabezal intercambiable con el avanzado recubrimiento de calidad AH715 para prolongar la vida útil de la herramienta, mejorar los acabados superficiales y aumentar la precisión del mecanizado.

Desafíos y tendencias

En la industria del automóvil, la maquinaria de construcción, el mecanizado general e incluso en campos relacionados con componentes de generadores, es esencial lograr una alta eficacia y estabilidad en los procesos diarios de producción en serie. Para los usuarios de fresas de mango macizo en particular, la prolongación de la vida útil de las herramientas sigue siendo un desafío crítico. El desgaste y la sustitución frecuentes de las herramientas no sólo reducen la productividad, sino que también aumentan la carga de los costes, lo que impulsa una fuerte demanda en todo el mercado de una mayor durabilidad.

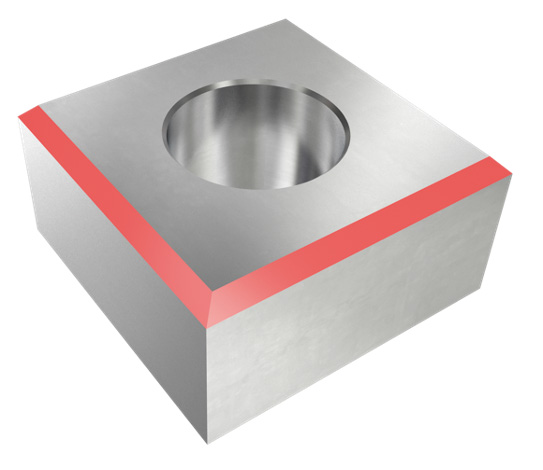

Además, con las fresas de mango convencionales, las múltiples pasadas en la dirección del eje Z a las paredes de la máquina pueden dar lugar a marcas de paso en las uniones de las pasadas. Este problema afecta significativamente a la calidad del acabado y a la precisión de la superficie mecanizada, lo que a menudo requiere un trabajo correctivo adicional en procesos posteriores. La solución de estos problemas y la consecución de un mecanizado más eficaz y de mayor calidad son objetivos muy esperados en muchos centros de fabricación.

Product Overview

TungMeister es la serie de fresas de cabezal intercambiable de alta eficiencia de Tungaloy. Ofrece flexibilidad con más de 45 opciones de forma de cabezal y una amplia gama de tamaños de 5 mm a 32 mm de diámetro. Fabricada con materiales de mango de alto rendimiento, satisface diversas necesidades de mecanizado y ofrece una productividad excepcional.

Benefits and Features

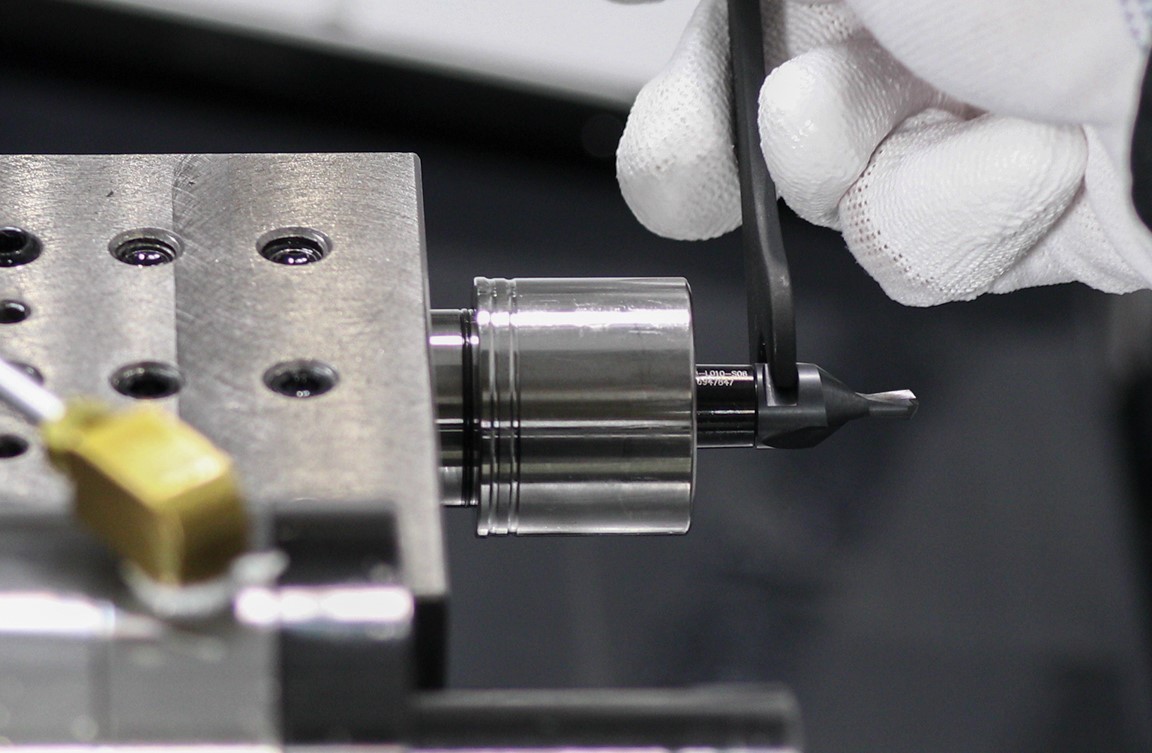

Feature 1: Simple and Quick Tool Replacement

The TUNGMEISTER system adopts a design where the cutting edge and shank are separated, allowing the head to be attached to the shank.

Eliminates the need for managing overhang length during tool replacement, significantly reducing tool replacement time.

Reduces machine downtime and boosts production efficiency.

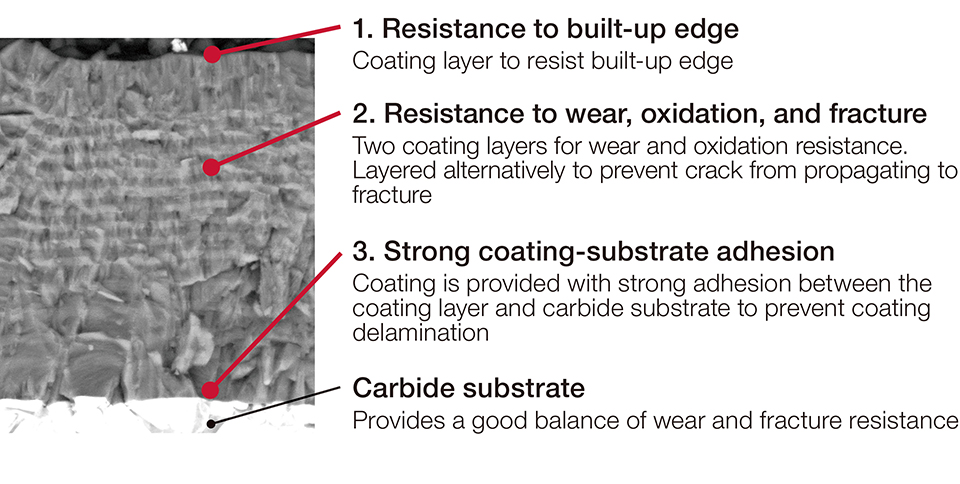

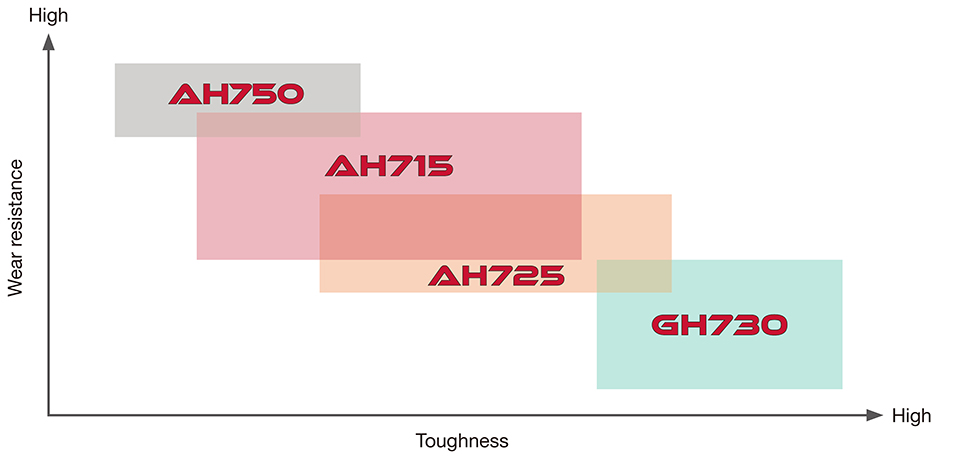

Feature 2: Superior Tool Life with “Triple Nano Technology” Coating

The AH715 utilizes a “Triple Nano Technology” coating, which incorporates Nano multilayer film technology.

Provides outstanding tool life compared to existing and competing grades in the machining of various materials.

Extended tool life reduces tool replacement frequency, contributing to cost reduction and improved productivity.

Feature 3: Enhanced Surface Finish Quality

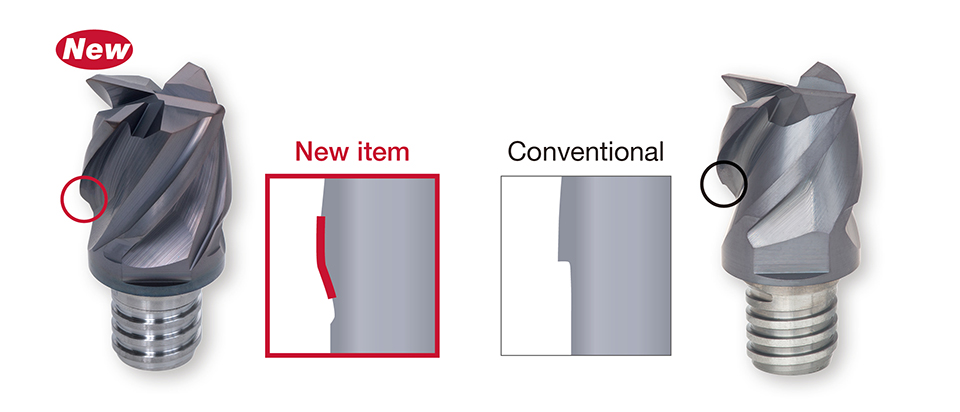

The newly expanded VEH-type square head features a design with an R added to the rear edge of the cutting blade.

Smoothly connects paths in the Z-axis direction, reducing step marks at the connection points.

This results in improved surface finish quality and achieves high-precision machining outcomes.

Cutting Performance

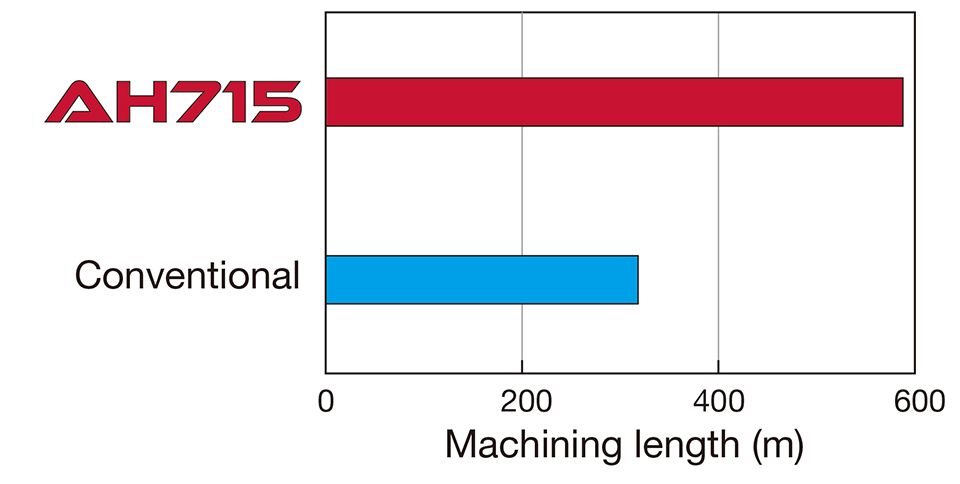

Tool Life Comparison: S55C / C55

| Shank | VSSD16L100S10-S |

| Head | VED160L12.0R05-04S10 AH715 |

| Workpiece material | S55C / C55 |

| Cutting speed / Feed per tooth | Vc = 150 m/min, fz = 0.12 mm/t |

| Depth / Width of cut | ap = 5 mm, ae = 1.5 mm |

| Coolant | Dry |

AH715 grade provided 2.0 x tool life increase.

Success Stories

IMPROVED PRODUCTIVITY

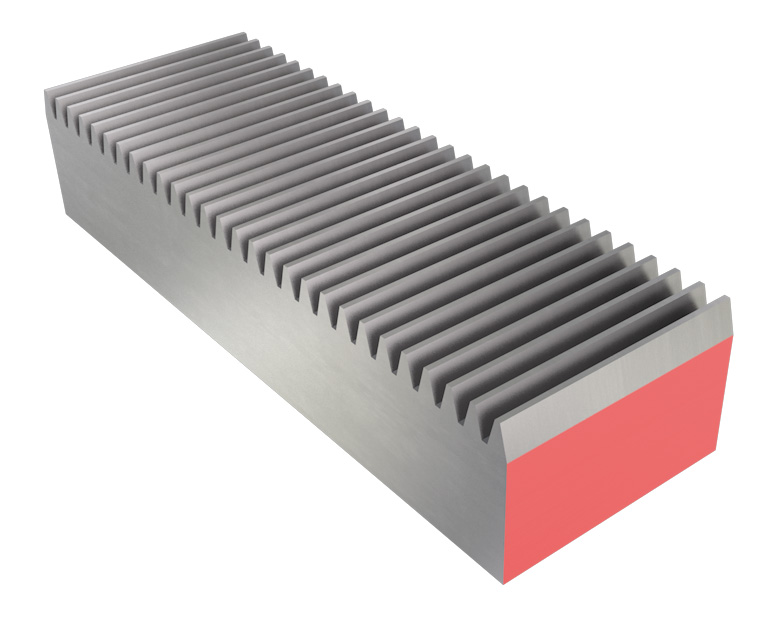

The VEH milling head enables a wider cutting width (ae), thanks to its excellent anti-vibration design and high-rigidity φ25 shank, thereby reducing the number of passes and improving cycle time.

| Industry | Automotive |

| Component | Rack |

| Material ISO code | P – Steel |

| Work material | SCM440/42CrMo4 |

| Machine(Spindle type) | Vertical Machining Center Middle (#40, HSK63) |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | TungMeister |

| TSR No. | 5108M |

IMPROVED PRODUCTIVITY AND TOOL LIFE

TungMeister, combined with built-up edge resistant AH715 grade, eliminated built-up edge and provided double tool life.

| Industry | Engineering |

| Component | Base plate |

| Material ISO code | M – Stainless steel |

| Work material | SUS430 |

| Machine(Spindle type) | Vertical Machining Center Middle(#40, HSK63) |

| Tool family | Milling |

| Tool category | Chamfering |

| Product name | TungMeister |

| TSR No. | 5109M |