Vollhartmetall-Bohrstange für Bohr- und Dreharbeiten mit kleinem Durchmesser

Steigert die Produktivität bei der Bearbeitung kleiner Teile

Anwendungen & Eigenschaften

Anwendungen

Eigenschaften

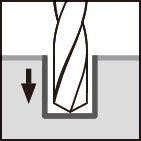

Multifunktionale Vollhartmetall-Bohrstange für Bohrungen mit kleinem Durchmesser und verschiedene Drehprozesse

Optimiertes Design sorgt für maximale Stabilität des Werkzeugs während der Bearbeitung

Anwendungsbereiche der multifunktionalen Bohr- und Drehwerkzeugserie

Ermöglicht mehrere Werkzeugkombinationen und Produktivitätssteigerungen bei der Bearbeitung kleiner Teile

- Ein einziges Werkzeug für mehrere Anwendungen

- Ermöglicht Werkzeugkombinationen und erhöht gleichzeitig die Anzahl der freien Revolverplätze oder in den Werkzeugaufnahmen Ihrer CNC-Drehmaschinen und Langdrehautomaten

- Erzeugt einen flachen Bohrungsgrund

Vollhartmetall-Bohrstangen und Sorten

Vollhartmetall-Bohrstangen

Sorten

SH725

![]()

![]()

- P20 – P30 / M20 – M30

- Hohe Verschleißfestigkeit

- Für die Bearbeitung von Stahl und rostfreiem Stahl

Hülsen

Praxis-Beispiele

Beispiel 1

| Werkstücktyp: | Achse |

| Werkstückstoff: | SUS316 / X5CrNiMo17-12-3 |

| Werkzeughalter: | JBBS19-7-L100C-4N |

| Wendeschneidplatte: | TBMFR0718003-D060 |

| Sorte: | SH725 |

| Schnittbedingungen: | Vc = 30 (m/min) f = 0.04 (mm/U) Bearbeitung: Bohren Kühlmittel: intern |

Beispiel 2

| Werkstücktyp: | Maschinenteil |

| Werkstückstoff: | S45C / C45 |

| Werkzeughalter: | JBBS254-7-L100C-4N |

| Wendeschneidplatte: | TBMFR0718003-D060 |

| Sorte: | SH725 |

| Schnittbedingungen: | Vc = 70 (m/min) f = 0.02 (mm/U) ap = 0.8 (mm) Bearbeitung: Innendrehen Kühlmittel: intern |

Beispiel 3

| Werkstücktyp: | Abstandhalter |

| Werkstückstoff: | SUS304 / X5CrNi18-9 |

| Werkzeughalter: | JBBS19-7-L100C-4N |

| Wendeschneidplatte: | TBMFR0712001-D060 |

| Sorte: | SH725 |

| Schnittbedingungen: | Vc = Bohren: 30, Drehen: 40 (m/min) f = Bohren: 0.015, Drehen : 0.03 (mm/U) ap = Drehen: 0.5 (mm) Bearbeitung: Bohren, Plandrehen und Innendrehen Kühlmittel: intern |

Standard-Schnittbedingungen

| ISO | Werkstückstoff | Sorte | Schnittgeschw.

Vc (m/min) |

|

|---|---|---|---|---|

| Bohren | Drehen | |||

| Stähle mit niedrigem Kohlenstoffgehalt S15C, S25C usw. C15E, C15E4 usw. |

SH725 | 20 – 100 | 40 – 140 | |

| Kohlenstoffstähle, legierte Stähle S55C, SCM440 usw. C55, 42CrMo4 usw. |

SH725 | 20 – 100 | 40 – 140 | |

| Gehärtete Stähle NAK80, PX5 etc. |

SH725 | 20 – 100 | 40 – 140 | |

| Rostfreie Stähle SUS304, SUS316 usw. X5CrNi18-9, X5CrNiMo17-12-3 usw. |

SH725 | 20 – 60 | 40 – 140 | |

| Grauguss FC250, FCD300 usw. GG25, 250, GG30, 300 usw. |

SH725 | 30 – 100 | 30 – 100 | |

| Kugelgraphitguss FC450, FCD600 usw. GGG60, 600-3 usw. |

SH725 | 30 – 100 | 30 – 100 | |

| Aluminiumlegierungen, Kupferlegierungen Si < 12 % |

SH725 | 50 – 200 | 90 – 200 | |

| Titanlegierungen Ti-6AI-4V usw. |

SH725 | 20 – 50 | 30 – 100 | |

| Superlegierungen Inconel718 usw. |

SH725 | 20 – 50 | 30 – 100 | |

L/D=2

| Anwendungsbereich | Mindestbohrungsdurchmesser: DMIN (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ø3 | ø4 | ø5 | ø6 | ø7 | ||||||

| Schnitttiefe ap (mm) |

Vorschub f (mm/U) |

Schnitttiefe ap (mm) |

Vorschub f (mm/U) |

Schnitttiefe ap (mm) |

Vorschub f (mm/U) |

Schnitttiefe ap (mm) |

Vorschub f (mm/U) |

Schnitttiefe ap (mm) |

Vorschub f (mm/U) |

|

| Innen- und Außendrehen |

0.2 – 1.5 | 0.01 – 0.08 | 0.2 – 2 | 0.01 – 0.08 | 0.2 – 2.5 | 0.01 – 0.08 | 0.2 – 3 | 0.01 – 0.08 | 0.3 – 3.5 | 0.01 – 0.08 |

| Plandrehen | 0.02 – 0.2 | 0.01 – 0.06 | 0.02 – 0.4 | 0.01 – 0.06 | 0.2 – 0.65 | 0.01 – 0.06 | 0.2 – 0.65 | 0.01 – 0.06 | 0.25 – 0.7 | 0.01 – 0.07 |

| Bohren | – | 0.01 – 0.06 | – | 0.01 – 0.06 | – | 0.01 – 0.08 | – | 0.01 – 0.08 | – | 0.01 – 0.1 |

L/D=3

| Anwendungsbereich | Mindestbohrungsdurchmesser: DMIN (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ø3 | ø4 | ø5 | ø6 | ø7 | ||||||

| Schnitttiefe ap (mm) |

Vorschub f (mm/U) |

Schnitttiefe ap (mm) |

Vorschub f (mm/U) |

Schnitttiefe ap (mm) |

Vorschub f (mm/U) |

Schnitttiefe ap (mm) |

Vorschub f (mm/U) |

Schnitttiefe ap (mm) |

Vorschub f (mm/U) |

|

| Innen- und Außendrehen |

– | – | 0.2 – 2 | 0.01 – 0.07 | 0.2 – 2.5 | 0.01 – 0.07 | 0.2 – 3 | 0.01 – 0.07 | – | – |

| Plandrehen | – | – | 0.02 – 0.4 | 0.01 – 0.04 | 0.2 – 0.65 | 0.01 – 0.04 | 0.2 – 0.65 | 0.01 – 0.04 | – | – |

| Bohren | – | – | – | 0.01 – 0.05 | – | 0.01 – 0.06 | – | 0.01 – 0.06 | – | – |

Weitere Informationen zu diesem Produkt finden Sie in unserem Online-E-Katalog oder laden Sie den Produktbroschüre herunter: