Kühlmittelgetriebene Hochgeschwindigkeits-Kompaktspindel

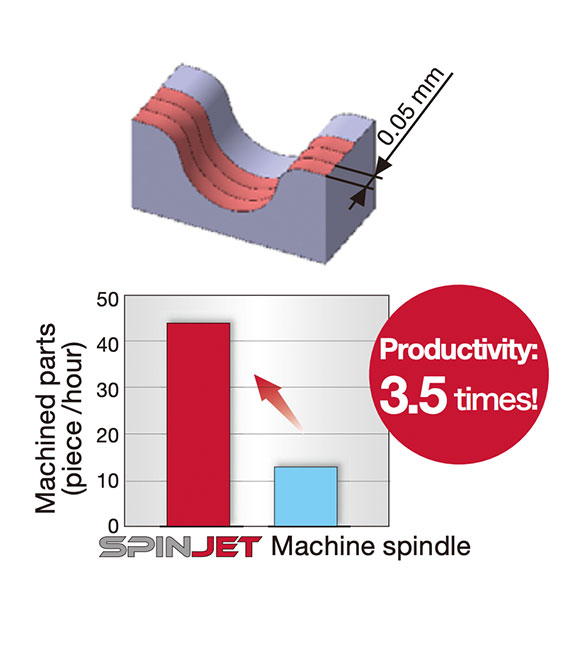

Vervierfachung der Produktivität durch Spindeln, die mit hoher Geschwindigkeit und Kühlmitteldruck rotieren

Eigenschaften

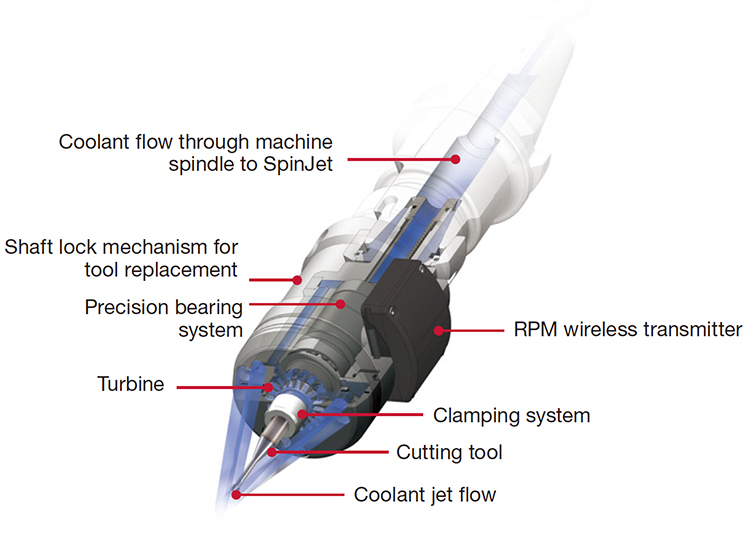

1. Kühlmittelgetriebene HSM-Spindel für hohe Produktivität mit Werkzeugen mit kleinem Durchmesser auf Maschinen mit begrenzten Drehzahlen

• SpinJet nutzt die vorhandene Kühlmittelzufuhr der Werkzeugmaschine, die von einer Hochdruckpumpe als Energiequelle angetrieben wird, um eine Turbine mit hoher Geschwindigkeit zu drehen.

• Ein starker Kühlmittelstrahl sorgt für eine verlängerte Werkzeugstandzeit und Bearbeitungsstabilität.

2. Energieeinsparung

• Die Werkzeuge drehen sich nur mit Kühlmitteldruck, und die Maschinenspindel ist im Leerlauf, während SpinJet in Betrieb ist.

Hinweis: Die Hauptspindel der Maschine sollte stillstehen, während die SpinJet-Spindel auf der Maschine montiert ist.

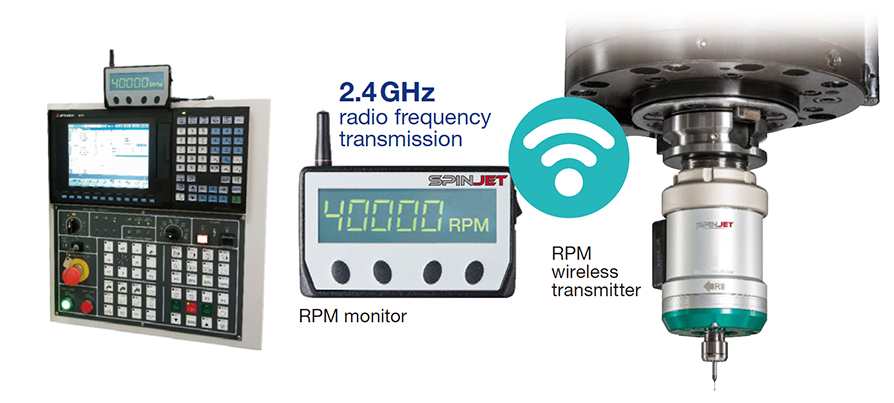

3. Drahtloses Drehzahlüberwachungssystem

• SpinJet ist mit einem Online-Drehzahlanzeige-System ausgestattet, das die tatsächliche Drehzahl des Schneidwerkzeugs während der Bearbeitung überwacht.

Halter & Zubehör

Praxis-Beispiele

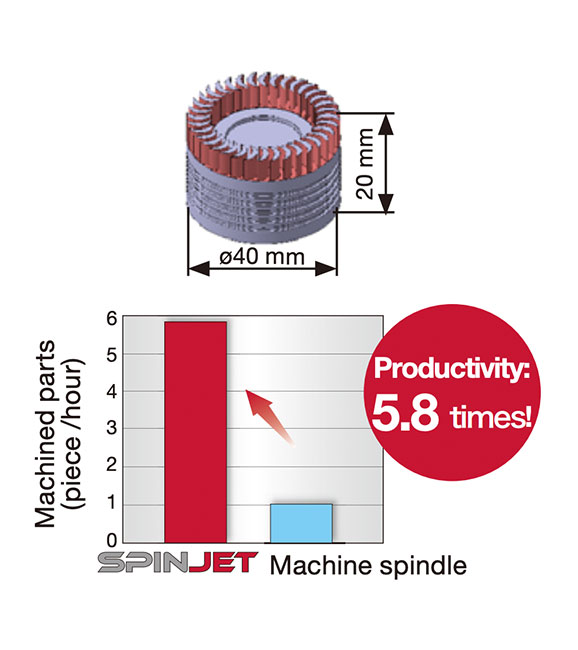

Beispiel 1

Allgemeiner Maschinenbau

| Werkstück: | Maschinenteile |

| Material: | SUS303 / X10CrNiS18-9 (25HRC) |

| Halter: | TJSGJETST20 |

| Schaftfräser: | TEB010A2-015/12C4M45 (ø1.0, z = 2) |

| Sorte: | AH750 |

| Schnittbedingungen: | Vc = 120 (m/min) n = 45,600 (RPM) fz = 0.016 (mm/Z) ap = 0.01 (mm) ae = 1 (mm) Anwendung: Stechen Kühlmittel: Nass Maschine: Vertikal M/C, BT30 |

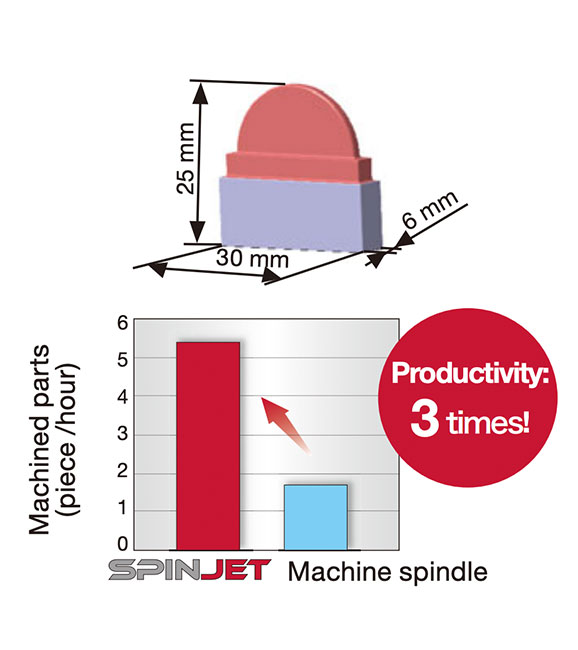

Beispiel 2

Werkzeug- und Formenbau

| Werkstück: | Elektrode |

| Material: | C1100 |

| Halter: | TJSGJETST20 |

| Schaftfräser: | TEB010A2-015/12C4M45 (ø1.0, z = 2) |

| Sorte: | AH750 |

| Schnittbedingungen: | Vc = 95 (m/min) n = 40,000 (RPM) fz = 0.025 (mm/Z) ap = 0.04 (mm) ae = 0.04 (mm) Anwendung: Profilieren Kühlmittel: Nass Maschine: Vertikal M/C, BT30 |

Beispiel 3

Medizintechnik

| Werkstück: | Medizinische Geräte |

| Material: | Titan-Legierungen |

| Halter: | TJSGJETER32 |

| Schaftfräser: | TEB010A2-015/12C4M45 (ø1.0, z = 2) |

| Sorte: | AH750 |

| Schnittbedingungen: | Vc = 80 (m/min) n = 35,000 (RPM) fz = 0.03 (mm/Z) ap = 0.03 (mm) ae = 0.05 (mm) Anwendung: Profilieren Kühlmittel: Nass Maschine: Vertikal M/C, BT30 |

Standard-Schnittbedingungen

TJS M00

| ISO | Material des Werkstücks | Werkzeug | Anwendung | Werkzeug-Ø DC (mm) |

Kühlmitteldruck (MPa) |

Spindeldrehzahl n (min-1) |

Schnittbreite ae (mm) |

Schnitttiefe ap (mm) |

Zahnvorschub fz (mm/Z) |

|---|---|---|---|---|---|---|---|---|---|

|

Legierter Stahl 35 HRC |

Bohrer | Bohren | 0.5 | 1.5 | 18,000 | – | – | 0.007 |

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 1 | 1.5 | 18,000 | – | – | 0.01 | ||||

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 2 | 1.5 | 18,000 | – | – | 0.01 | ||||

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| Kugelkopf-Fräser | Profilieren | 1 | 1.5 | 18,000 | – | 0.05 | 0.003 | ||

| 2 | 23,000 | – | 0.05 | 0.003 | |||||

| 3 | 31,000 | – | 0.05 | 0.003 | |||||

| 4 | 40,000 | – | 0.05 | 0.003 | |||||

| 2 | 1.5 | 18,000 | – | 0.08 | 0.004 | ||||

| 2 | 23,000 | – | 0.08 | 0.004 | |||||

| 3 | 31,000 | – | 0.08 | 0.004 | |||||

| 4 | 40,000 | – | 0.08 | 0.004 | |||||

| 3 | 1.5 | 18,000 | – | 0.1 | 0.006 | ||||

| 2 | 23,000 | – | 0.1 | 0.006 | |||||

| 3 | 31,000 | – | 0.1 | 0.006 | |||||

| 4 | 40,000 | – | 0.1 | 0.006 | |||||

| Schaftfräser | Schlitzen | 1 | 1.5 | 18,000 | 1 | 0.1 | 0.006 | ||

| 2 | 23,000 | 1 | 0.1 | 0.006 | |||||

| 3 | 31,000 | 1 | 0.1 | 0.006 | |||||

| 4 | 40,000 | 1 | 0.15 | 0.006 | |||||

| 2 | 1.5 | 18,000 | 2 | 0.12 | 0.01 | ||||

| 2 | 23,000 | 2 | 0.12 | 0.01 | |||||

| 3 | 31,000 | 2 | 0.14 | 0.01 | |||||

| 4 | 40,000 | 2 | 0.14 | 0.01 | |||||

| 3 | 1.5 | 18,000 | 3 | 0.12 | 0.01 | ||||

| 2 | 23,000 | 3 | 0.12 | 0.01 | |||||

| 3 | 31,000 | 3 | 0.12 | 0.01 | |||||

| 4 | 40,000 | 3 | 0.15 | 0.01 | |||||

| Schulterfräsen | 2 | 1.5 | 18,000 | 0.5 | 0.5 | 0.002 | |||

| 2 | 23,000 | 0.5 | 0.5 | 0.014 | |||||

| 3 | 31,000 | 0.5 | 0.5 | 0.017 | |||||

| 4 | 40,000 | 0.5 | 0.5 | 0.018 | |||||

|

Rostfreier Stahl 180 – 250 HB |

Bohrer | Bohren | 0.5 | 1.5 | 18,000 | – | – | 0.015 |

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.015 | |||||

| 4 | 40,000 | – | – | 0.015 | |||||

| 1 | 1.5 | 18,000 | – | – | 0.015 | ||||

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.015 | |||||

| 4 | 40,000 | – | – | 0.015 | |||||

| 2 | 1.5 | 18,000 | – | – | 0.015 | ||||

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.015 | |||||

| 4 | 40,000 | – | – | 0.015 | |||||

| Schaftfräser | Schlitzen | 1 | 1.5 | 18,000 | 1 | 0.1 | 0.015 | ||

| 2 | 23,000 | 1 | 0.1 | 0.015 | |||||

| 3 | 31,000 | 1 | 0.15 | 0.015 | |||||

| 4 | 40,000 | 1 | 0.15 | 0.015 | |||||

| 2 | 1.5 | 18,000 | 2 | 0.15 | 0.015 | ||||

| 2 | 23,000 | 2 | 0.15 | 0.015 | |||||

| 3 | 31,000 | 2 | 0.15 | 0.015 | |||||

| 4 | 40,000 | 2 | 0.2 | 0.015 | |||||

| Schulterfräsen | 2 | 1.5 | 18,000 | 0.35 | 0.15 | 0.02 | |||

| 2 | 23,000 | 0.35 | 0.15 | 0.02 | |||||

| 3 | 31,000 | 0.4 | 0.15 | 0.02 | |||||

| 4 | 40,000 | 0.5 | 0.18 | 0.025 | |||||

|

Aluminiumlegierung 80 – 160 HB |

Bohrer | Bohren | 0.5 | 1.5 | 18,000 | – | – | 0.01 |

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 1 | 1.5 | 18,000 | – | – | 0.01 | ||||

| 2 | 23,000 | – | – | 0.01 | |||||

| 3 | 31,000 | – | – | 0.01 | |||||

| 4 | 40,000 | – | – | 0.01 | |||||

| 2 | 1.5 | 18,000 | – | – | 0.015 | ||||

| 2 | 23,000 | – | – | 0.015 | |||||

| 3 | 31,000 | – | – | 0.017 | |||||

| 4 | 40,000 | – | – | 0.018 | |||||

| Kugelkopf-Fräser | Profilieren | 1 | 1.5 | 18,000 | – | 0.05 | 0.003 | ||

| 2 | 23,000 | – | 0.05 | 0.003 | |||||

| 3 | 31,000 | – | 0.05 | 0.003 | |||||

| 4 | 40,000 | – | 0.13 | 0.003 | |||||

| 2 | 1.5 | 18,000 | – | 0.08 | 0.004 | ||||

| 2 | 23,000 | – | 0.08 | 0.004 | |||||

| 3 | 31,000 | – | 0.08 | 0.004 | |||||

| 4 | 40,000 | – | 0.15 | 0.004 | |||||

| 3 | 1.5 | 18,000 | – | 0.08 | 0.006 | ||||

| 2 | 23,000 | – | 0.09 | 0.006 | |||||

| 3 | 31,000 | – | 0.09 | 0.006 | |||||

| 4 | 40,000 | – | 0.15 | 0.006 | |||||

| Schaftfräser | Schlitzen | 1 | 1.5 | 18,000 | 1 | 0.1 | 0.025 | ||

| 2 | 23,000 | 1 | 0.1 | 0.025 | |||||

| 3 | 31,000 | 1 | 0.15 | 0.025 | |||||

| 4 | 40,000 | 1 | 0.15 | 0.025 | |||||

| 2 | 1.5 | 18,000 | 2 | 0.2 | 0.025 | ||||

| 2 | 23,000 | 2 | 0.2 | 0.025 | |||||

| 3 | 31,000 | 2 | 0.2 | 0.025 | |||||

| 4 | 40,000 | 2 | 0.2 | 0.025 | |||||

| Schulterfräsen | 2 | 1.5 | 18,000 | 0.5 | 0.25 | 0.02 | |||

| 2 | 23,000 | 0.5 | 0.25 | 0.02 | |||||

| 3 | 31,000 | 0.5 | 0.5 | 0.02 | |||||

| 4 | 40,000 | 0.5 | 0.5 | 0.025 |

TJS M90

| ISO | Material des Werkstücks | Werkzeug | Anwendung | Werkzeug-Ø DC (mm) |

Kühlmitteldruck (MPa) |

Spindeldrehzahl n (min-1) |

Schnittbreite ae (mm) |

Schnitttiefe ap (mm) |

Zahnvorschub fz (mm/Z) |

|---|---|---|---|---|---|---|---|---|---|

|

Vorgehärteter Stahl 35 HRC |

Bohrer | Bohren | 0.5 | 2 | 35,000 | – | – | 0.01 |

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 1 | 2 | 35,000 | – | – | 0.01 | ||||

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 2 | 2 | 35,000 | – | – | 0.01 | ||||

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| Kugelkopf-Fräser | Profilieren | 1 | 2 | 35,000 | – | 0.05 | 0.003 | ||

| 3 | 44,000 | – | 0.05 | 0.003 | |||||

| 4 | 53,000 | – | 0.05 | 0.003 | |||||

| 2 | 2 | 35,000 | – | 0.08 | 0.004 | ||||

| 3 | 44,000 | – | 0.08 | 0.004 | |||||

| 4 | 53,000 | – | 0.08 | 0.004 | |||||

| 3 | 2 | 35,000 | – | 0.1 | 0.006 | ||||

| 3 | 44,000 | – | 0.1 | 0.006 | |||||

| 4 | 53,000 | – | 0.1 | 0.006 | |||||

| Schaftfräser | Schlitzen | 0.5 | 2 | 35,000 | 0.5 | 0.05 | 0.006 | ||

| 3 | 44,000 | 0.5 | 0.05 | 0.006 | |||||

| 4 | 53,000 | 0.5 | 0.05 | 0.006 | |||||

| 1 | 2 | 35,000 | 1 | 0.1 | 0.006 | ||||

| 3 | 44,000 | 1 | 0.1 | 0.006 | |||||

| 4 | 53,000 | 1 | 0.15 | 0.006 | |||||

| 2 | 2 | 35,000 | 2 | 0.12 | 0.01 | ||||

| 3 | 44,000 | 2 | 0.14 | 0.01 | |||||

| 4 | 53,000 | 2 | 0.14 | 0.01 | |||||

| 3 | 2 | 35,000 | 3 | 0.12 | 0.01 | ||||

| 3 | 44,000 | 3 | 0.12 | 0.01 | |||||

| 4 | 53,000 | 3 | 0.15 | 0.01 | |||||

| Schulterfräsen | 2 | 2 | 35,000 | 0.5 | 0.5 | 0.001 | |||

| 3 | 44,000 | 0.5 | 0.5 | 0.017 | |||||

| 4 | 53,000 | 0.5 | 0.5 | 0.018 | |||||

|

Rostfreier Stahl SUS316 35 HRC |

Bohrer | Bohren | 0.5 | 2 | 35,000 | – | – | 0.015 |

| 3 | 44,000 | – | – | 0.015 | |||||

| 4 | 53,000 | – | – | 0.015 | |||||

| 1 | 2 | 35,000 | – | – | 0.015 | ||||

| 3 | 44,000 | – | – | 0.015 | |||||

| 4 | 53,000 | – | – | 0.015 | |||||

| 2 | 2 | 35,000 | – | – | 0.015 | ||||

| 3 | 44,000 | – | – | 0.015 | |||||

| 4 | 53,000 | – | – | 0.015 | |||||

| Schaftfräser | Schlitzen | 1 | 2 | 35,000 | 1 | 0.1 | 0.015 | ||

| 3 | 44,000 | 1 | 0.15 | 0.015 | |||||

| 4 | 53,000 | 1 | 0.15 | 0.015 | |||||

| 2 | 2 | 35,000 | 2 | 0.15 | 0.015 | ||||

| 3 | 44,000 | 2 | 0.15 | 0.015 | |||||

| 4 | 53,000 | 2 | 0.2 | 0.015 | |||||

| Schulterfräsen | 2 | 2 | 35,000 | 0.35 | 0.15 | 0.02 | |||

| 3 | 44,000 | 0.4 | 0.15 | 0.02 | |||||

| 4 | 53,000 | 0.5 | 0.18 | 0.025 | |||||

|

Aluminiumlegierung ADC12 28 HRC |

Bohrer | Bohren | 0.5 | 2 | 35,000 | – | – | 0.01 |

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 1 | 2 | 35,000 | – | – | 0.01 | ||||

| 3 | 44,000 | – | – | 0.01 | |||||

| 4 | 53,000 | – | – | 0.01 | |||||

| 2 | 2 | 35,000 | – | – | 0.015 | ||||

| 3 | 44,000 | – | – | 0.017 | |||||

| 4 | 53,000 | – | – | 0.018 | |||||

| Kugelkopf-Fräser | Profilieren | 1 | 2 | 35,000 | – | 0.05 | 0.003 | ||

| 3 | 44,000 | – | 0.05 | 0.003 | |||||

| 4 | 53,000 | – | 0.13 | 0.003 | |||||

| 2 | 2 | 35,000 | – | 0.08 | 0.004 | ||||

| 3 | 44,000 | – | 0.08 | 0.004 | |||||

| 4 | 53,000 | – | 0.15 | 0.004 | |||||

| 3 | 2 | 35,000 | – | 0.08 | 0.006 | ||||

| 3 | 44,000 | – | 0.09 | 0.006 | |||||

| 4 | 53,000 | – | 0.15 | 0.006 | |||||

| Schaftfräser | Schlitzen | 0.5 | 2 | 35,000 | 0.5 | 0.1 | 0.02 | ||

| 3 | 44,000 | 0.5 | 0.12 | 0.02 | |||||

| 4 | 53,000 | 0.5 | 0.15 | 0.02 | |||||

| 1 | 2 | 35,000 | 1 | 0.1 | 0.025 | ||||

| 3 | 44,000 | 1 | 0.15 | 0.025 | |||||

| 4 | 53,000 | 1 | 0.15 | 0.025 | |||||

| 2 | 2 | 35,000 | 2 | 0.2 | 0.025 | ||||

| 3 | 44,000 | 2 | 0.2 | 0.025 | |||||

| 4 | 53,000 | 2 | 0.2 | 0.025 | |||||

| Schulterfräsen | 2 | 2 | 35,000 | 0.5 | 0.25 | 0.02 | |||

| 3 | 44,000 | 0.5 | 0.5 | 0.02 | |||||

| 4 | 53,000 | 0.5 | 0.5 | 0.025 | |||||

|

Werkzeugstahl SKD61 58 HRC |

Kugelkopf-Fräser | Profilieren | 1 | 2 | 35,000 | – | 0.05 | 0.005 |

| 3 | 44,000 | – | 0.05 | 0.005 | |||||

| 4 | 53,000 | – | 0.05 | 0.005 | |||||

| 2 | 2 | 35,000 | – | 0.07 | 0.006 | ||||

| 3 | 44,000 | – | 0.08 | 0.006 | |||||

| 4 | 53,000 | – | 0.08 | 0.006 | |||||

| 3 | 2 | 35,000 | – | 0.08 | 0.006 | ||||

| 3 | 44,000 | – | 0.1 | 0.006 | |||||

| 4 | 53,000 | – | 0.1 | 0.006 |

Weitere Informationen zu diesem Produkt finden Sie in unserem Online-Katalog oder im Produktbericht, den Sie herunterladen können:

Kontakt zu Tungaloy in Bezug auf SpinJet

Wenn Sie Unterstützung von Tungaloy benötigen, kontaktieren Sie uns bitte über das folgende Kontaktformular