Enables High-Speed Machining with Small Tools, Usable in Automatic Lathes and #30-taper Machines

Iwaki, Japan, June 24, 2024 – Tungaloy Corporation (President: Satoshi Kinoshita, Headquarters: Iwaki, Fukushima) announces the addition of a compact type to its coolant-driven high-speed spindle “SpinJet” series.

Overview

SpinJet is a high-speed spindle driven by coolant (cutting fluid) that rotates a dedicated turbine, enabling high-speed and high-efficiency machining with small diameter tools for pocket-milling and other operations. Because it rotates solely with coolant, there is no need for an electric connection, making it very easy to install and deploy on machines. Additionally, the coolant is discharged near the cutting edge, which aids in cooling the cutting edge.

The newly added compact type features a 10 mm diameter shank and can be gripped by spring collet chucks, hydro chucks, etc. With an overall length of approximately 60 mm and a maximum diameter of approximately 30 mm, it can be used in places where medium diameter tools cannot reach due to interference from jigs or parts. Furthermore, it is applicable not only to machining centers and turning centers but also to narrow space machines like automatic lathes.

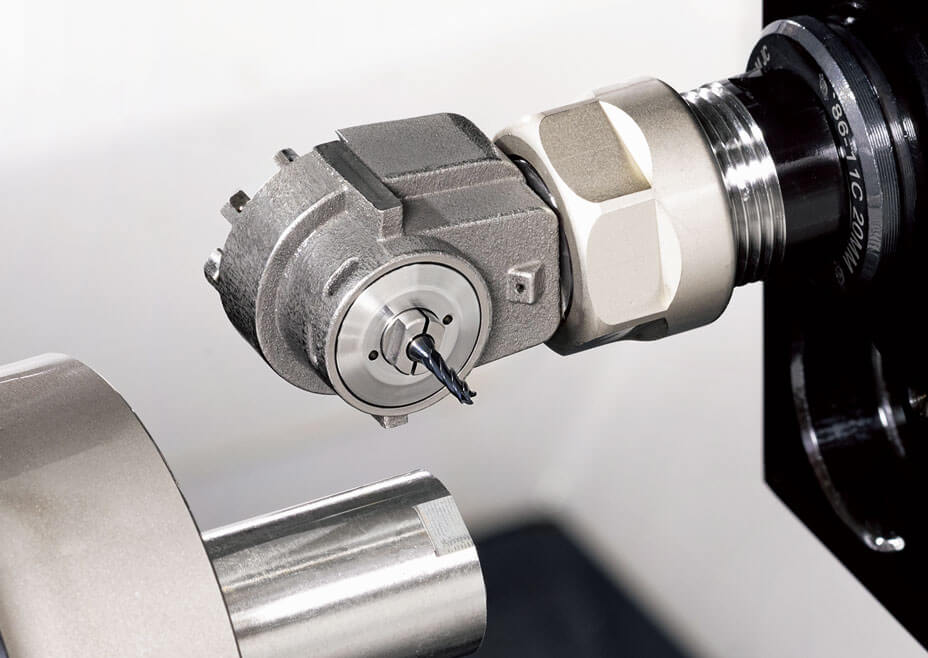

The compact type comes in two versions: “TJS M00” with the tool axis the same as the machine spindle, and “TJS M90” with the tool axis oriented 90 degrees to the machine spindle as an angle head type. It operates at coolant pressures of 1.5 to 4 MPa, achieving rotational speeds of 18,000 to 40,000 min-1. It can be used with tools up to 2.0 mm in diameter for drilling and up to 3.5 mm in diameter for end milling.

With the addition of this compact type, high-efficiency machining with small diameter tools is now possible even in compact machines such as automatic lathes and #30-taper machines, greatly contributing to productivity improvements for a wide range of customers.

Product information

No. 428S2-G (Metric)

SpinJet