Vollhartmetall-Bohrstange für das Drehen von kleinen Durchmessern

Extrafeine Schneide bietet hochpräzise Bearbeitung für eine breite Palette von Innenanwendungen

Anwendungen & Eigenschaften

Anwendungen

Eigenschaften

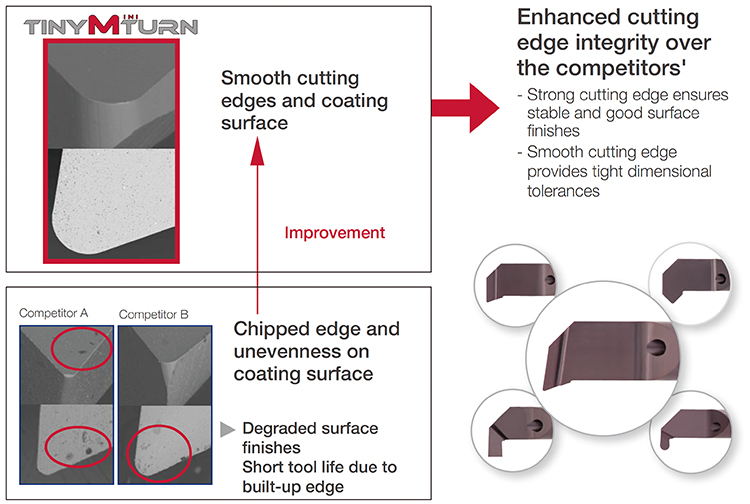

1. Starke Schneidkante

Optimierte Geometrie und Beschichtung.

2. Erweitertes Programm für eine Vielzahl von Drehbearbeitungen von Bohrungen mit kleinem Durchmesser

Komplettes Programm mit 146 Vollhartmetall-Bohrstangen – Mindestbohrdurchmesser: øDm = 0,6 mm

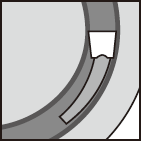

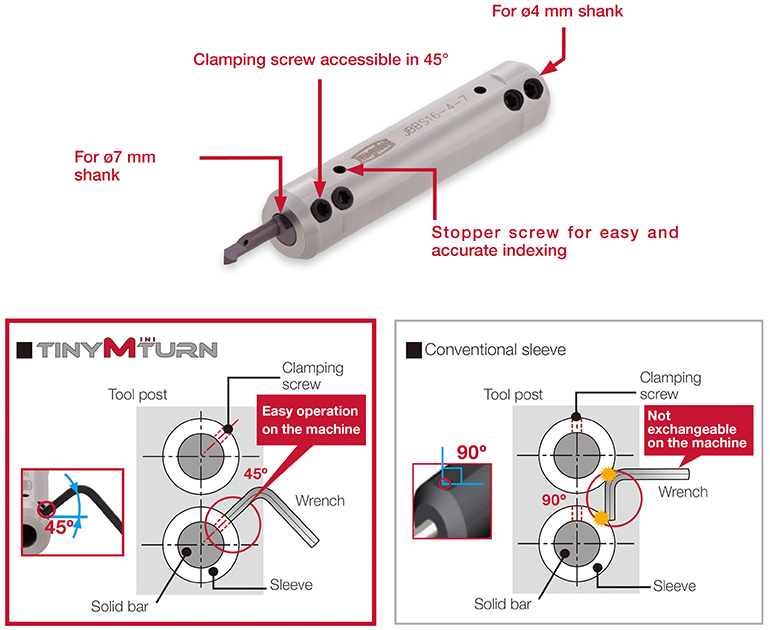

3. Hochpräzise Spannzangenhülsen

Funktionelle TinyMiniTurn-Hülsen sorgen für Stabilität beim Bohren von Löchern mit kleinem Durchmesser.

Vollhartmetall-Bohrstangen & Sorten

Vollhartmetall-Bohrstangen

Innen-Gewindeschneiden

TinyMini-Turn für Innen-Gewindeschneiden

- Bohrstangen aus Vollhartmetall

Grades

SH725

![]()

![]()

- P20 – P30 / M20 – M30

- Hohe Verschleißfestigkeit

- Entwickelt für die Bearbeitung von Stahl und rostfreiem Stahl

BX310

![]()

- H01 – H10

- Hohe Verschleißfestigkeit

- Konzipiert für das kontinuierliche Hochgeschwindigkeitsschneiden von gehärtetem Stahl

Wendeschneidplatten & Sorten

Wendeschneidplatten

Haupt-Sorten

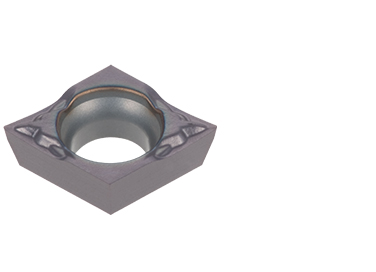

SH7025

![]()

![]()

- P20 – P30 / M20 – M30

- Die neueste Sorte mit scharfer Schneide für die Kleinteilebearbeitung

- Eine Kombination aus säulenförmig strukturierter TiCN-Beschichtung und mehrlagiger TiAlN-Beschichtung sorgt für eine hervorragende Oberflächenqualität und Prozesssicherheit

SH725

![]()

![]()

- P20 – P30 / M20 – M30

- Hohe Verschleißfestigkeit

- Entwickelt für die Bearbeitung von Stahl und rostfreiem Stahl

GH110

![]()

![]()

![]()

![]()

![]()

- P10 – P20 / M10 – M20 / K10 – K25 / N05 – N15 / S10 – S20

- Hohe Verschleißfestigkeit

J740

- Ultrafeinkörniges Hartmetall, das mit einer TiN-basierten Verbindung beschichtet ist

GT9530

![]()

![]()

- Hohe Verschleißfestigkeit

- Ausgezeichnete Oberflächenqualität beim Schlichten

NS9530

![]()

![]()

- Hohe Bruchsicherheit

- Geeignet für das Schlichten bis zum mittleren Schnitt von Stahl

TH10

![]()

![]()

![]()

![]()

- P10 / M10 / K10 / N10

- Unbeschichtetes Hartmetall

BX310

![]()

- H01 – H10

- Hohe Verschleißfestigkeit

- Konzipiert für das kontinuierliche Hochgeschwindigkeitsschneiden von gehärtetem Stahl

BX470

![]()

- Ausgezeichnete Schärfe

- Geeignet für eisenhaltiges Sintermetall

DX140

![]()

- Hohe Verschleißfestigkeit

- Entwickelt für die Bearbeitung von Nichteisenmetallen und Nichtmetallen

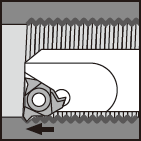

Indexierbare Werkzeughalter

Aufnahmen

Anwendungsbeispiele

Standard-Schnittbedingungen

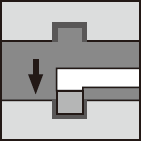

Bohren, Profilieren, Anfasen, Aufbohren

| ISO | Werkstoffe des Werkstücks | Sorte | Schnittgeschw. Vc (m/min) | Vorschub f (mm/U) |

|---|---|---|---|---|

|

Stähle mit niedrigem Kohlenstoffgehalt S15C, S25C, usw. C15E, C15E4, usw. |

SH725 | 40 – 140 | 0.01 – 0.08 |

| Kohlenstoffstähle, legierte Stähle S55C, SCM440, usw. C55, 42CrMo4, usw. |

SH725 | 40 – 140 | 0.01 – 0.08 | |

| Vorvergütete Stähle NAK80, PX5, usw. |

SH725 | 40 – 140 | 0.01 – 0.08 | |

|

Rostfreie Stähle SUS304, SUS316, usw. X5CrNi18-9, X5CrNiMo17-12-3, usw. |

SH725 | 40 – 140 | 0.01 – 0.08 |

|

Grauguss FC250, FCD300, usw. GG25, 250, GG30, 300, usw. |

SH725 | 30 – 100 | 0.01 – 0.08 |

| Kugelgraphitguss FC450, FCD600, etc. GGG60, 600-3, etc. |

SH725 | 30 – 100 | 0.01 – 0.08 | |

|

Aluminium-Legierungen, Kupferlegierungen Si < 12% |

SH725 | 90 – 200 | 0.01 – 0.08 |

|

Titan-Legierungen Ti-6AI-4V, etc. |

SH725 | 30 – 100 | 0.01 – 0.08 |

| Superlegierungen Inconel718, etc. |

SH725 | 30 – 100 | 0.01 – 0.08 | |

|

Gehärteter Stahl | BX310 | 15 – 100 | 0.01 – 0.1 * |

* Schnitttiefe und Vorschub entsprechend dem Eckenradius (RE) des Werkzeugs einstellen.

Gewindeschneiden (metrisches Gewinde)

| ISO | Werkstoffe des Werkstücks | Sorte | Schnittgeschw. Vc (m/min) |

Anzahl der Pässe Neigung (mm) |

||||

|---|---|---|---|---|---|---|---|---|

| 0.5 | 0.75 | 1 | 1.25 | 1.5 | ||||

|

Stähle mit niedrigem Kohlenstoffgehalt S15C, S25C, usw. C15E, C15E4, usw. |

SH725 | 40 – 140 | 6 – 8 | 8 – 10 | 10 – 12 | 12 – 15 | 15 – 18 |

| Kohlenstoffstähle, legierte Stähle S55C, SCM440, usw. C55, 42CrMo4, usw. |

SH725 | 40 – 140 | 6 – 8 | 8 – 10 | 10 – 12 | 12 – 15 | 15 – 18 | |

| Vorvergütete Stähle NAK80, PX5, usw. |

SH725 | 40 – 140 | 6 – 8 | 8 – 10 | 10 – 12 | 12 – 15 | 15 – 18 | |

|

Rostfreie Stähle SUS304, SUS316, usw. X5CrNi18-9, X5CrNiMo17-12-3, usw. |

SH725 | 40 – 140 | 8 | 10 | 12 | 15 | 18 |

|

Grauguss FC250, FCD300, usw. GG25, 250, GG30, 300, usw. |

SH725 | 30 – 100 | 7 | 9 | 12 | 14 | 17 |

| Kugelgraphitguss FC450, FCD600, etc. GGG60, 600-3, etc. |

SH725 | 30 – 100 | 7 | 9 | 12 | 14 | 17 | |

|

Aluminium-Legierungen, Kupferlegierungen Si < 12% |

SH725 | 90 – 200 | 6 | 8 | 10 | 12 | 15 |

Innen-Stechen

| ISO | Werkstoffe des Werkstücks | Sorte | Schnittgeschw. Vc (m/min) |

Vorschub f (mm/U) |

|---|---|---|---|---|

|

Stähle mit niedrigem Kohlenstoffgehalt S15C, S25C, usw. C15E, C15E4, usw. |

SH725 | 40 – 140 | 0.01 – 0.03 |

| Kohlenstoffstähle, legierte Stähle S55C, SCM440, usw. C55, 42CrMo4, usw. |

SH725 | 40 – 140 | 0.01 – 0.03 | |

| Vorvergütete Stähle NAK80, PX5, usw. |

SH725 | 40 – 140 | 0.01 – 0.03 | |

|

Rostfreie Stähle SUS304, SUS316, usw. X5CrNi18-9, X5CrNiMo17-12-3, usw. |

SH725 | 40 – 140 | 0.01 – 0.03 |

|

Grauguss FC250, FCD300, usw. GG25, 250, GG30, 300, usw. |

SH725 | 30 – 100 | 0.01 – 0.03 |

| Kugelgraphitguss FC450, FCD600, etc. GGG60, 600-3, etc. |

SH725 | 30 – 100 | 0.01 – 0.03 | |

|

Aluminium-Legierungen, Kupferlegierungen Si < 12% |

SH725 | 90 – 200 | 0.01 – 0.03 |

|

Titan-Legierungen Ti-6AI-4V, etc. |

SH725 | 30 – 100 | 0.01 – 0.03 |

| Superlegierungen Inconel718, etc. |

SH725 | 30 – 100 | 0.01 – 0.03 |

Stirnseitiges Stechen

| ISO | Werkstoffe des Werkstücks | Sorte | Schnittgeschw. Vc (m/min) |

Vorschub f (mm/U) |

|---|---|---|---|---|

|

Stähle mit niedrigem Kohlenstoffgehalt S15C, S25C, usw. C15E, C15E4, usw. |

SH725 | 40 – 140 | 0.01 – 0.05 |

| Kohlenstoffstähle, legierte Stähle S55C, SCM440, usw. C55, 42CrMo4, usw. |

SH725 | 40 – 140 | 0.01 – 0.05 | |

| Vorvergütete Stähle NAK80, PX5, usw. |

SH725 | 40 – 140 | 0.01 – 0.05 | |

|

Rostfreie Stähle SUS304, SUS316, usw. X5CrNi18-9, X5CrNiMo17-12-3, usw. |

SH725 | 40 – 140 | 0.01 – 0.05 |

|

Grauguss FC250, FCD300, usw. GG25, 250, GG30, 300, usw. |

SH725 | 30 – 100 | 0.01 – 0.05 |

| Kugelgraphitguss FC450, FCD600, etc. GGG60, 600-3, etc. |

SH725 | 30 – 100 | 0.01 – 0.05 | |

|

Aluminium-Legierungen, Kupferlegierungen Si < 12% |

SH725 | 90 – 200 | 0.01 – 0.05 |

|

Titan-Legierungen Ti-6AI-4V, etc. |

SH725 | 30 – 100 | 0.01 – 0.05 |

| Superlegierungen Inconel718, etc. |

SH725 | 30 – 100 | 0.01 – 0.05 |

Für neue Wechsel-Bohrstangen (EPG*04 / EPG*03)

| ISO | Material des Werkstücks | Sorte | Schnittgeschw. Vc (m/min) |

|---|---|---|---|

|

Stähle mit niedrigem Kohlenstoffgehalt S15C, S25C, usw. C15E, C15E4, usw. Kohlenstoffstähle S45C, S55C, usw. C45, C55, usw. Legierte Stähle SCM440, SCr420, usw. 42CrMo4, 20Cr4, usw. |

SH7025 | 10 – 200 |

| SH725 | 10 – 200 | ||

| SH730 | 10 – 150 | ||

| J740 | 10 – 100 | ||

| NS9530 | 150 – 300 | ||

| GT9530 | 150 – 300 | ||

|

Rostfreie Stähle SUS304, SUS316, usw. X5CrNi18-9, X5CrNiMo17-12-3, usw. |

SH7025 | 10 – 200 |

| SH725 | 10 – 200 | ||

| SH730 | 10 – 150 | ||

|

Grauguss FC250, GG25, 250, usw. |

TH10 | 30 – 100 |

|

Aluminium-Legierungen Si < 12% |

TH10 | > 100 |

| DX140 | > 500 | ||

| Aluminium-Legierungen Si > 12% |

TH10 | > 100 | |

| DX140 | > 400 | ||

| Kupferlegierungen | TH10 | > 100 | |

| DX140 | > 500 | ||

|

Gehärtete Materialien | BX310 | 30 – 150 |

| Pulverförmiges Metall | Gesinterte Pulvermetalle | BX470 | 100 – 300 |

Weitere Informationen zu diesem Produkt finden Sie in unserem Online-Katalog oder im Produktbericht, den Sie herunterladen können: