Einfach zu indexierende Fräser für überlegene Oberflächenqualität

Hohe Zuverlässigkeit, Stabilität und Effizienz

Anwendungen & Merkmale

Anwendungen

Merkmale

Hervorragende Oberflächenqualität

- Keine Axial-/Radialrundlauf-Justage erforderlich.

- Die Plattensitze sind so ausgelegt, dass die Schlicht‑Wendeschneidplatte stets die Schlichtbearbeitung übernimmt und eine konstante Oberflächenrauheit gewährleistet.

- Leichtschnittgeometrie mit Wiper-Schneide, die einen großen Kreisbogen integriert.

Erste Wahl

- Bietet überlegene Oberflächenqualität

Leichtschnitt

- Erzeugt Leichtschnitt mit hervorragender Oberflächenqualität – dank derselben Wipergeometrie wie bei LNCQ0906N‑100L.

Für sehr leichten Schnitt und Schlichten nahe an Schultern

- Geringere Radialkräfte

- Ermöglicht minimale Beeinträchtigung der Schulterflächen beim Bearbeiten schnittkraftbelasteter Werkstück‑Ecken

Optimierung der Wendeschneidplatten‑Kombinationen für dünnwandige Werkstücke und Schulterbereiche

Wendeschneidplatten & Sorten

Wendeschneidplatten

Sorten

AH120

![]()

![]()

![]()

![]()

- Gute Balance zwischen Verschleiß- und Bruchfestigkeit

- Geeignet für die Bearbeitung von Stahl, Edelstahl und Gusseisen unter allgemeinen Schnittbedingungen

GH110

![]()

![]()

![]()

![]()

![]()

- Hohe Verschleißfestigkeit

NS740

![]()

- Hohe Bruchzähigkeit und Thermorissbeständigkeit

- Hochfeste Sorte zum Fräsen

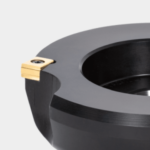

Fräser

Praktische Beispiele

Beispiel Nr. 1

| Werkstücktyp: | Bauteil für die Expansionskammer |

| Material des Werkstücks: | SUS304 / X5CrNi18-9 |

| Fräser: | NMS09160R |

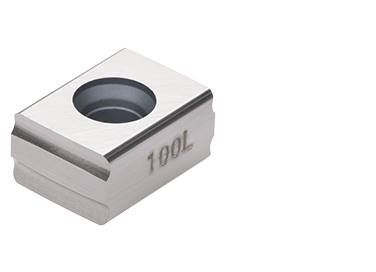

| Wendeschneidplatte: | LNCQ0906N-100L |

| Sorte: | AH120 |

| Schnittbedingungen: | Vc = 180 (m/min) f = 3 (mm/U) ap = 0.1 (mm) ae = 130 (mm) Bearbeitung: Planfräsen Kühlmittel: Extern Maschine: Horizontale M/C BT50 |

Beispiel #2

| Werkstücktyp: | Zylindergehäuse |

| Material des Werkstücks: | FC250 / 250 |

| Fräser: | NMS09160R |

| Wendeschneidplatte: | LNCQ0906N-100L |

| Sorte: | AH120 |

| Schnittbedingungen: | Vc = 200 (m/min) f = 3 (mm/U) ap = 0.15 (mm) ae = 110 (mm) Bearbeitung: Planfräsen Kühlmittel: trocken Maschine: Vertikale M/C BT50 |

Beispiel #3

| Werkstücktyp: | Platte |

| Material des Werkstücks: | SCM440 / 42CrMo4 |

| Fräser: | NMS09160R |

| Wendeschneidplatte: | LNCQ0906N-100L |

| Sorte: | NS740 |

| Schnittbedingungen: | Vc = 200 (m/min) f = 2 (mm/U) ap = 0.1 (mm) ae = 110 (mm) Bearbeitung: Planfräsen Kühlmittel: Trocken Maschine: Vertikale M/C BT50 |

Standard-Schnittbedingungen

| ISO | Werkstückmaterial | Härte (HB) |

Sorte | Schnittgeschwindigkeit Vc (m/min) |

LNCQ0906N-100(50)L | LNCQ0906R-50S | ||

|---|---|---|---|---|---|---|---|---|

| Schnitttiefe APMX (mm) |

Zahnvorschub f (mm/U) |

Schnitttiefe APMX (mm) |

Zahnvorschub f (mm/U) |

|||||

|

Weichstähle SS400, etc. E275A, etc. |

< 180 | NS740 | 200 – 300 | < 0.2 | 2 – 6 | ≤ 0.2 | 1 – 2.5 |

| Kohlenstoffstähle S55C, etc. C55, etc. |

< 300 | NS740 | 150 – 250 | |||||

| Legierte Stähle SCM440, etc. 42CrMo4, etc. |

< 300 | NS740 | 120 – 200 | |||||

| Werkzeugstahl SKD61, etc. X40CrMoV5-1, etc. |

< 300 | NS740 | 100 – 150 | |||||

|

Edelstähle SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-3, etc. |

< 250 | AH120 NS740 |

150 – 220 | < 0.2 | 2 – 6 | ≤ 0.2 | 1 – 2.5 |

|

Gusseisen FC250, etc. 250, etc. |

150 – 250 | GH110 AH120 |

120 – 200 | < 0.2 | 2 – 6 | ≤ 0.2 | 1 – 2.5 |

Für weitere Informationen zu diesem Produkt besuchen Sie unseren Online-E-Katalog oder laden Sie den Produktbericht herunter: