Beschichtete CBN Sorte für gehärteten Stahl

Beschichtete CBN-Serie für eine Vielzahl von Hartbearbeitungen

Die ideale Sorte kann je nach Anwendung ausgewählt werden.

Anwendungen & Eigenschaften

Anwendungen

Eigenschaften

1. Anwendungsbereich

2. Eigenschaften der Sorte

3. WavyJoint

Neue Löttechnologie für mehr Effizienz bei der Bearbeitung

- Eine maximale Schnitttiefe von bis zu 0,8 mm.

Reduziert die Anzahl der Durchgänge und erhöht die Produktivität - Innovative WavyJoint-Löttechnologie

Verhindert das Ausbröckeln der CBN-Spitzen, wodurch abrupte Wendeschneidplattenbrüche bei der anspruchsvollen Trockenbearbeitung vermieden werden und gleichzeitig stabile und vorhersehbare Bearbeitungen von hochfestem Stahl gewährleistet werden.

4. Serie Hardbreakder

- HS-Spanbrecher

Optimiertes Spanbrecherdesign für hervorragende Spankontrolle beim Hartdrehen unter aggressiven Bedingungen - HP-Spanbrecher

Entwickelt für die Fertigbearbeitung von gehärteten Teilen mit engen Toleranzen - HF- und HM-Spanbrecher

Geeignet für Hartdrehanwendungen, die eine hohe Schnitttiefe erfordern, wie z.B. die Entfernung von Aufkohlungsschichten

5. Neue CBN-Wendeschneidplatten für das allgemeine Drehen

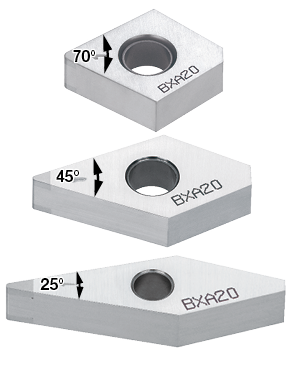

- GNGA-Wendeschneidplatte mit 70°-Eckwinkel

- FNGA-Wendeschneidplatte mit 45°-Eckwinkel

- Ein kleinerer Eckenwinkel verschafft der Wendeschneidplatte mehr Freiraum zwischen der Wendeschneidplattenflanke und der Werkstückoberfläche, was einen besseren Spanfluss und eine bessere Spanabfuhr ermöglicht.

- Ermöglicht einen größeren Außendurchmesser beim Plandrehen, bei dem die Wendeschneidplatte nach außen (von der Werkstückmitte weg) gezogen wird.

- YNGA-Wendeschneidplatte mit 25°-Winkel

- Ermöglicht Hinterschneiden, V-Einstechen und andere Anwendungen, die mit herkömmlichen V-Wendeschneidplatten nicht möglich sind.

Hohe Vielseitigkeit

- Für diese Wendeschneidplatten können bestehende ISO-Drehhalter verwendet werden:

- GNGA-Wendeschneidplatte: Halter für CNxx1204

- FNGA-Wendeschneidplatte: Halter für DNxx1504

- YNGA-Wendeschneidplatte: Halter für VNxx1604

- Keine Anpassungen erforderlich, da die Schneidkantengeometrie gleich bleibt.

- Doppelseitige Wendeschneidplatte mit 2 Schneidkanten.

6. MiniForce-Turn Doppelseitige positive Wendeschneidplatte mit CBN-Spitzen

MiniForce-Turn bietet nun Wendeschneidplatten aus CBN an, die zusätzliche Festigkeit und Sicherheit unter aggressiven Schneidbedingungen bieten.

WXGQ0403… Wendeschneidplatte

7. CBN-Wiper-Wendeschneidplatten-Serie für erweiterten Anwendungsbereich

Erhältlich mit HP-Spanbrecher und HS-Spanbrecher für eine effektive Spankontrolle. Wendeschneidplatten ohne Spanbrecher sind ebenfalls erhältlich.

Der FW- Wiper verhindert die Ratterbildung bei langsameren Vorschüben und bietet gute Oberflächengüte der Teile.

Der MW- Wiper bietet verbesserte Oberflächengüte bei höherem Vorschub.

Anwendungsbereiche

Sorten

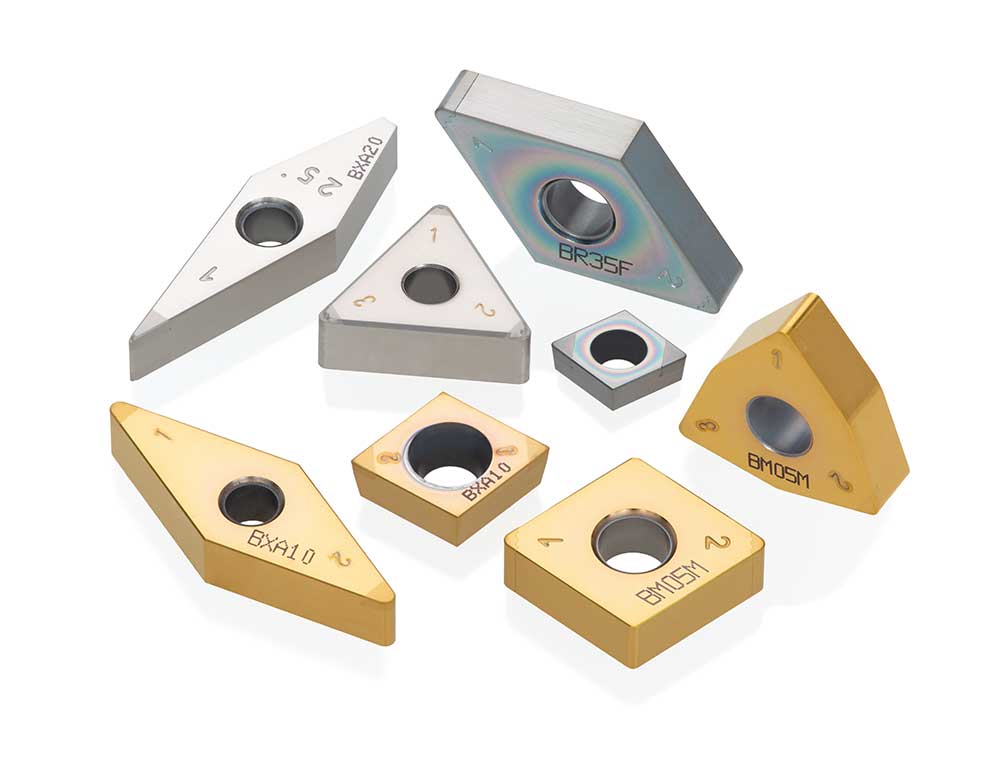

BXA10

![]()

- Erste Wahl für kontinuierliche bis leicht unterbrochene Schnitte beim Drehen von gehärtetem Stahl

- Für Schnittgeschwindigkeiten = 230 m/min oder weniger

BXA20

![]()

- Vielseitige Sorte von kontinuierlichen bis zu stark unterbrochenen Schnitten

- Für Schnittgeschwindigkeit = 180 m/min oder weniger

BR35F

![]()

- Erste Wahl für stark unterbrochene Schnitte

- Für Schnittgeschwindigkeiten = 150 m/min oder weniger

Praxis-Beispiele

Beispiel 1

Autoindustrie

| Werkstücktyp: | Getriebe |

| Material: |

SCM420 / 18CrMo4 (62HRC) |

| Wendeschneidplatte: |

2QP-CNGA120408 |

| Sorte: | BXA10 |

| Schnittbedingungen: | Vc = 100 (m/min) f = 0.05 (mm/U) ap = 0.15 (mm) Kühlmittel: Trocken |

Beispiel 2

Autoindustrie

| Werkstücktyp: | CVT |

| Material: |

SCr420 / 20Cr4 (59HRC) |

| Wendeschneidplatte: |

2QP-DNGA150412 |

| Sorte: | BXA20 |

| Schnittbedingungen: | Vc = 170 (m/min) f = 0.3 (mm/U) ap = 0.1 (mm) Kühlmittel: Nass |

Beispiel 3

Autoindustrie

| Werkstücktyp: | Getriebe |

| Material: |

SCM420 / 18CrMo4 (60HRC) |

| Wendeschneidplatte: |

2QP-CNGA120412HC |

| Sorte: |

BR35F |

| Schnittbedingungen: | Vc = 70 (m/min) f = 0.05 (mm/U) ap = 0.15 (mm) Kühlmittel: Trocken |

Standard-Schnittbedingungen

| ISO | Grade | Workpiece condition | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed f (mm/rev) |

|---|---|---|---|---|---|

|

BM05M | Continuous | 200 – 350 | 0.05 – 0.2 | 0.05 – 0.2 |

| BXA10 | Continuous | 100 – 230 | 0.05 – 0.5 | 0.05 – 0.3 | |

| Light interrupted | 100 – 230 | 0.05 – 0.3 | 0.05 – 0.2 | ||

| BXA20 | Continuous | 60 – 180 | 0.05 – 0.5 | 0.05 – 0.3 | |

| Interrupted | 60 – 180 | 0.05 – 0.3 | 0.05 – 0.2 | ||

| BR35F | Heavy interrupted | 50 – 150 | 0.05 – 0.3 | 0.05 – 0.2 |

Weitere Informationen zu diesem Produkt finden Sie in unserem Online-Katalog oder im Produktbericht, den Sie herunterladen können: