Iwaki, Japan – May, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungBoreMini series, now offering a ø7 shank version optimized for small-diameter machining. This new addition enables flexible mounting on a variety of automatic lathes by being compatible with sleeves from the existing TinyMiniTurn series, enhancing versatility and productivity.

Challenges and Trends

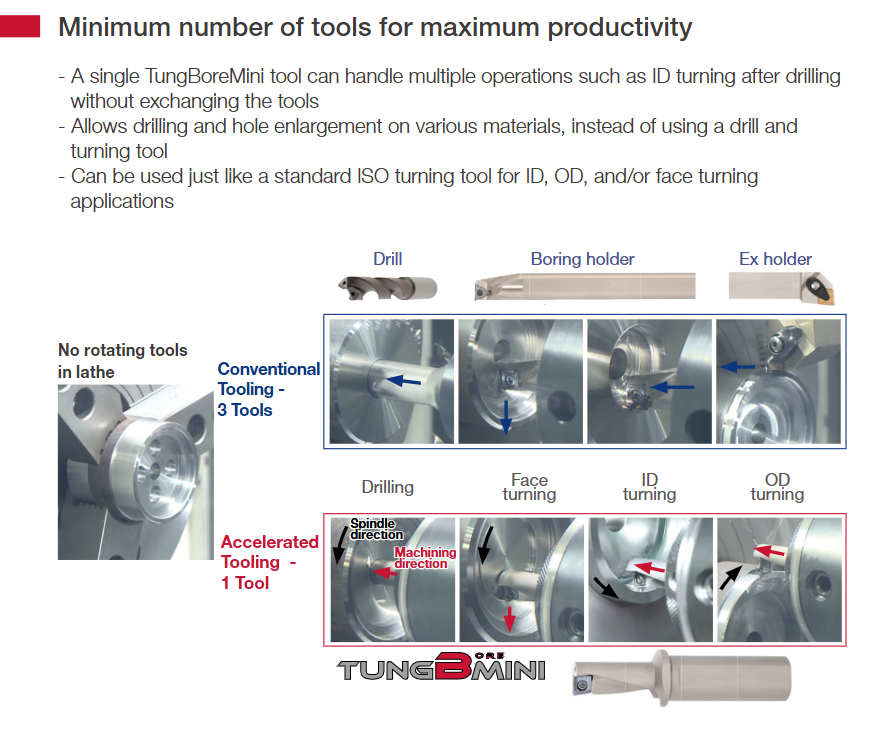

In small-part machining, efficient drilling and turning operations are essential. However, conventional small-diameter solid carbide bars often suffer from inadequate chip evacuation, leading to machining troubles and defects. Additionally, the need to use separate tools for drilling and internal/external turning increases setup time and tool changes, becoming a barrier to improving productivity. As the demand for high-mix, low-volume production continues to grow, there is a need for tools that can address these challenges.

Product Overview

TungBoreMini is a multifunctional composite tool capable of performing both drilling and turning operations with a single tool. Its high-rigidity structure and excellent chip evacuation performance contribute to reduced machining time and significantly improved productivity. It supports a minimum machining diameter starting from ø8 mm.

Benefits and Features

Feature 1: Excellent Chip Control

- Indexable inserts with 3D chipbreakers efficiently break and evacuate chips

- Reduces the risk of machine stoppages and defects by minimizing chip-related issues, even in small-diameter machining

- Maintains a stable cutting environment, making it ideal for continuous operation on automatic lathe

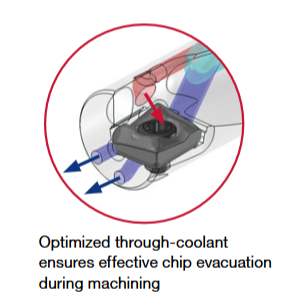

Feature 2: Optimized Coolant Supply

- Internal coolant-compatible design ensures precise cooling and lubrication at the cutting edge

- Enhances chip evacuation and suppresses tool wear, contributing to longer tool life

- When combined with the TinyMiniTurn 4-port coolant sleeve, it further prevents chip entanglement and enhances machining stability

Feature 3: Expanded Compatibility with ø7 Shank for Automatic Lathes

- New ø7 shank supports minimum machining diameter of ø8

- Compatible with TinyMiniTurn sleeves, enabling easy integration with existing automatic lathe setups

- Increases tool replacement flexibility and accommodates a wider range of machining applications

Cutting Performance

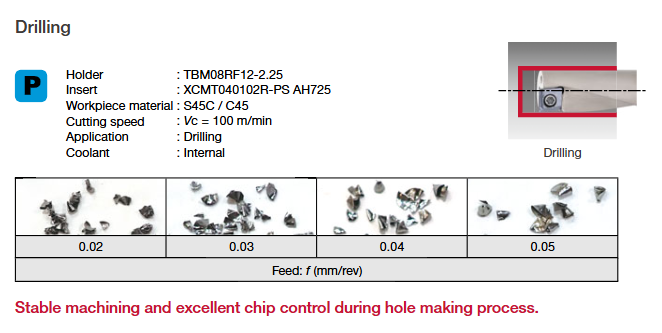

Drilling

| Holder | TBM08RF12-2.25 |

| Insert | XCMT040102R-PS AH725 |

| Workpiece material | S45C / C45 |

| Cutting speed | Vc = 100 m/min |

| Application | Drilling |

| Coolant | Internal |

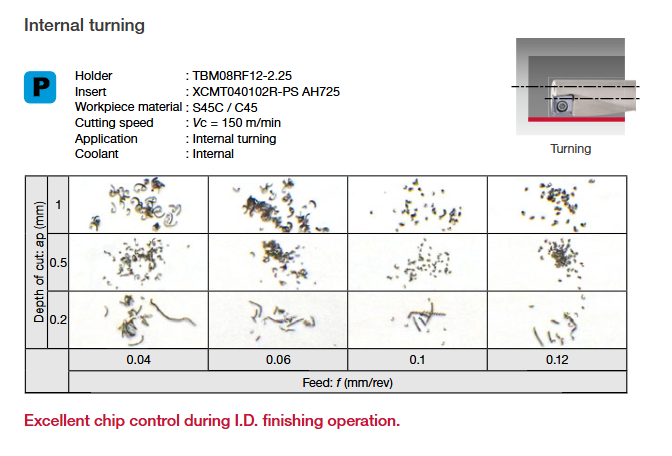

Internal turning

| Holder | TBM08RF12-2.25 |

| Insert | XCMT040102R-PS AH725 |

| Workpiece material | S45C / C45 |

| Cutting speed | Vc = 150 m/min |

| Application | Internal turning |

| Coolant | Internal |

Success Stories

IMPROVED PROCESS TIME

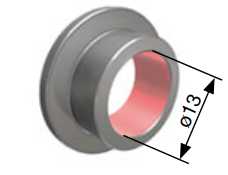

Traditionally, machining a Ø13 hole required three different tools—a leading drill, an Ø8 drill, and a boring tool.

By switching to the TungBoreMini, all operations were consolidated into a single tool, eliminating tool changes and helping to reduce the cycle time of the machining process.

| Industry | Engineering |

| Component | Machine Parts |

| Material ISO code | |

| Work material | S45C/C45 |

| Machine (spindle type) | Swiss Lathe |

| Tool family | Turning |

| Tool category | Internal turning |

| Product name | TungBoreMini |

| TSR No. | 5241T |