Iwaki, Japan – December 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TetraMini-Cut, featuring new insert widths and corner radii ideal for ultra‑narrow grooves around 1 mm and precision E‑ring groove machining.

Challenges and Trends

In the field of small-part machining, the demand for finer and more complex groove machining has been increasing along with product weight reduction and higher precision requirements. In particular, grooves for E-rings and ultra-narrow grooves around 1 mm in width make it difficult to achieve both machining accuracy and tool life, and many users have faced challenges in selecting the optimal tool. Until now, the TetraMini-Cut series had limited specifications to accommodate such narrow-width grooves, which restricted the range of applications that could be proposed. However, as the demand for small-part machining continues to grow in markets such as electronic components and precision equipment, there is a strong need to further expand the range of supported applications.

Product Overview

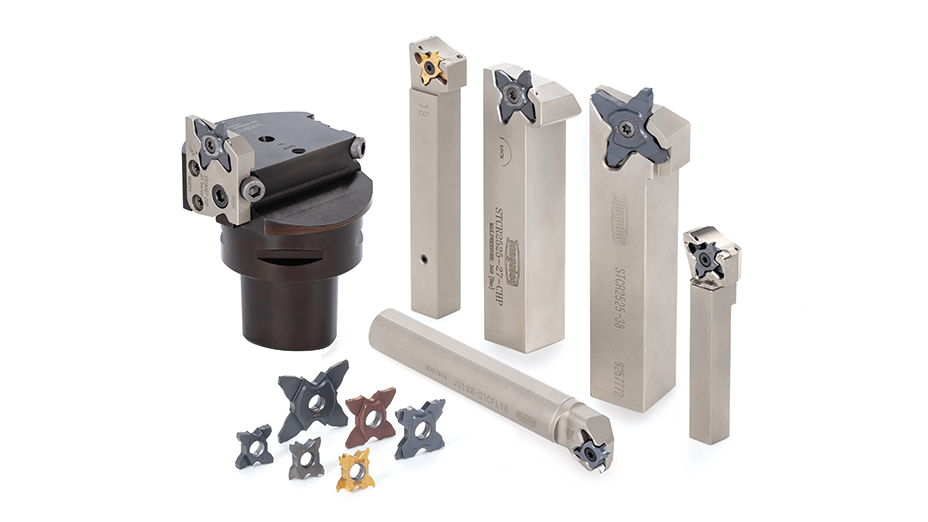

TetraMini-Cut is high-precision grooving and parting tools developed by Tungaloy. They cover a wide range of applications, from small-diameter components to heavy-duty cutting. Featuring a low-resistance chip breaker and a highly rigid clamping structure, these tools deliver stable machining and excellent surface finishes. With internal coolant capability, they are also ideal for high-efficiency machining.

Benefits and Features

Feature 1: High versatility with a wide range of groove widths and corner radius

– Newly added cutting widths support E-ring grooves and precision grooves as narrow as 1 mm

– A variety of corner radius options enable optimal machining for different workpiece shapes and accuracy requirements

– A single holder can accommodate a broad range of machining conditions, improving flexibility in production lines

Feature 2: Stable machining performance through optimized cutting edge design

– High-precision cutting edge geometry enhances the surface finish at the groove bottom

– Contributing to longer tool life and consistent quality