Iwaki, Japan – March, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TetraMini-Cut series with the addition of two new grades: AH8005 for high-speed machining, and AH6235 for interrupted machining, addressing diverse machining challenges while enhancing tool life and productivity.

Challenges and Trends

In the automotive industry and small parts machining sectors, there is a growing demand for improving efficiency and reducing costs in grooving and parting-off operations. Specifically, challenges arise in external groove machining of shafts, machining of fuel nozzle components, fittings, and medical parts, where tool life becomes a critical issue. For grooving operations in interrupted cuts, the occurrence of burrs and instability in tool life hinder productivity improvements. Additionally, in parting-off operations, variations in insert lifespan are a significant concern for users. There is a strong demand for solutions that ensure high-quality finishes while controlling the increase in tooling costs. Against this backdrop, expectations are rising for tool grades that offer both enhanced durability and stability.

Product Overview

TetraMini-Cut is a high-performance grooving and parting tool offered by Tungaloy. It is capable of machining a wide range of materials, including steel, stainless steel, and difficult-to-cut materials. It supports grooving up to a maximum width of 3.5 mm and parting of diameters up to Ø6 mm. With its high-precision cutting edge positioning and cost-effective four-corner insert design, TetraMini-Cut ensures stable machining and excellent cost efficiency.

Benefits and Features

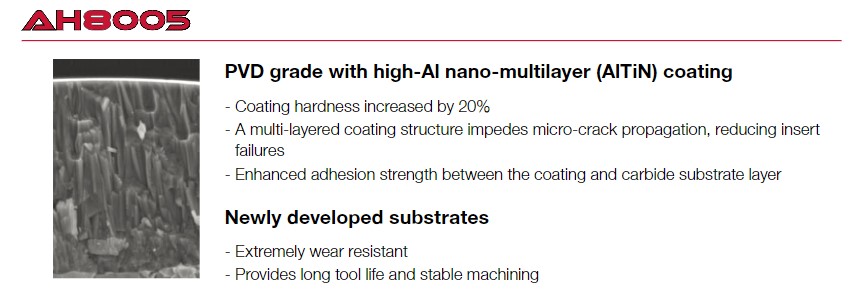

Feature 1: AH8005 – Optimal Wear Resistance for High-Speed Machining

Features a high-hardness, high-Al coating and a wear-resistant carbide substrate for extended tool life.

Designed for use in high-speed machining and stable machining environments, enhancing productivity.

Excels under specific machining conditions, such as side cutting, supporting machining efficiency.

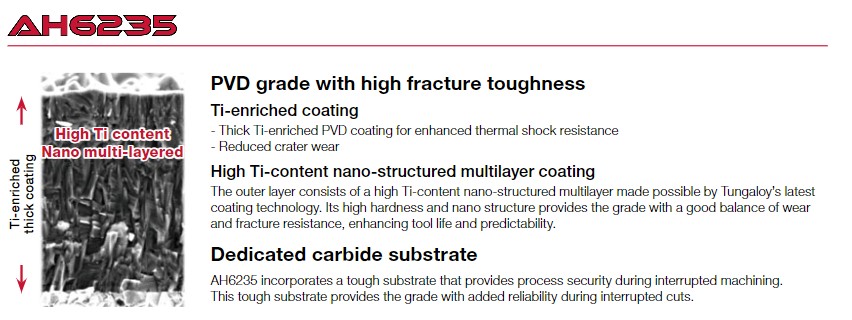

Feature 2: AH6235 – Enhanced Chipping Resistance

Incorporates a high-Ti nano-layered coating designed to suppress crack propagation.

Utilizes a high-toughness substrate to ensure stable tool life under harsh machining conditions, such as interrupted cutting or grooving.

Improves reliability in challenging machining scenarios, reducing machining costs.

Success Stories

Improve tool life

TetraMini-Cut provided strong insert clamping for added tool rigidity, successfully minimizing the number of passes, which the competitor tool with weak clamping could not achieved. With AH6235 grade insert, tool life has increased by 1.3 times.

| Industry | Engineering |

| Component | Sleeve |

| Material ISO code | P – Steel |

| Work material | C45 / S45C |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TetraMini-Cut |

| TSR No. | 5161G |