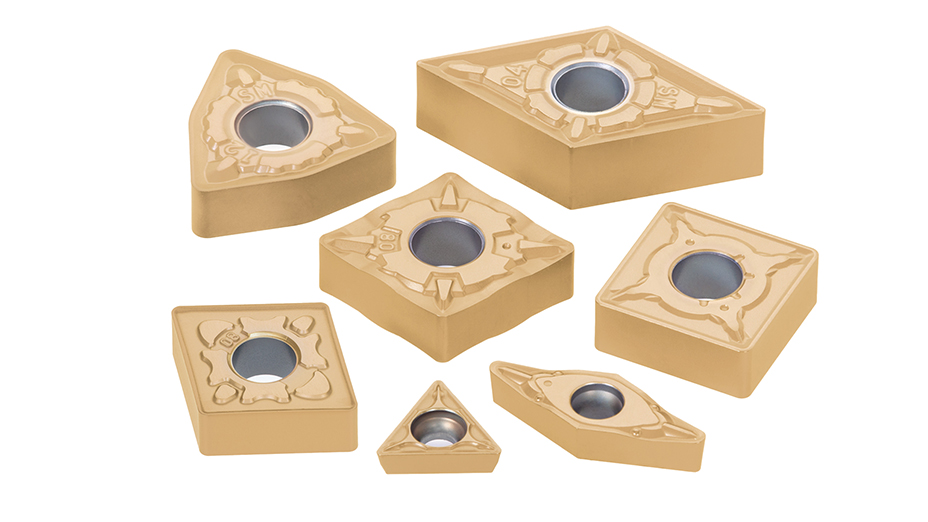

Iwaki, Japan – August, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its T6200 and AH6200 series with the introduction of the new CVD grade T6225, engineered for superior tool life and process reliability in stainless steel machining across diverse cutting conditions.

Challenges and Trends

In the machining of stainless steel, extending tool life and ensuring stable cutting performance are constant demands, with particularly high expectations in general machining and the automotive industry. In the manufacturing of critical components such as shafts, joints, pistons, and valves, there is a strong need for tools with excellent wear resistance. Existing grades have sometimes fallen short in performance compared to competitor products. Due to these Challenges and Market Conditions, the demand for higher-performance cutting grades is increasing.

Product Overview

The T6200 and AH6200 series are the latest turning grades specifically developed for stainless steel machining. T6215 is ideal for high-speed and continuous cutting, while T6225 is a CVD grade optimized for the M25 application range, effectively bridging the gap between T6215 and AH6225. AH6225 is the first-choice grade for stainless steel machining, and AH6235 is best suited for interrupted and heavy cutting, offering excellent wear and fracture resistance. This advanced series is suitable for all types of machining operations.

Benefits and Features

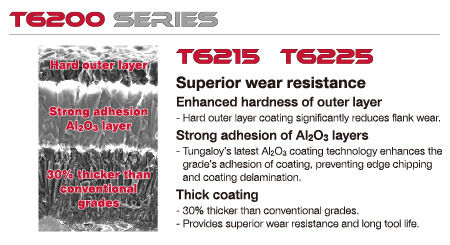

Feature 1: Excellent Balance of Wear Resistance and Fracture Toughness

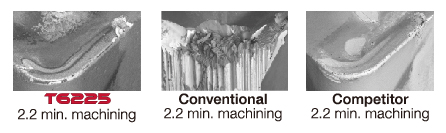

– The T6225 utilizes a newly developed high-adhesion Al₂O₃ coating that significantly suppresses chipping and coating delamination.

– The high-hardness outer layer enhances resistance to flank wear, delivering stable machining performance.

– A coating thickness 1.3 times greater than conventional products dramatically extends tool life and reduces replacement frequency.

Feature 2: Suitable for a Wide Range of Applications

– T6225 is a CVD grade optimized for the M25 range, bridging the gap between T6215 and AH6225.

– It offers high versatility by covering a broad range of stainless steel machining from M20 to M30.

– The four-grade system of the T6200 series (T6215, T6225) and AH6200 series (AH6225, AH6235) allows optimal tool selection based on machining conditions and objectives.

Feature 3: High Versatility and Stable Machining

– With an outstanding balance of wear and fracture resistance, T6225 performs reliably even in interrupted cuts and under unstable machining conditions.

– Its high coating adhesion maintains performance during extended continuous machining.

– Its adaptability to a wide variety of work materials and cutting conditions contributes to simplified tool management and cost reduction.

Success Stories

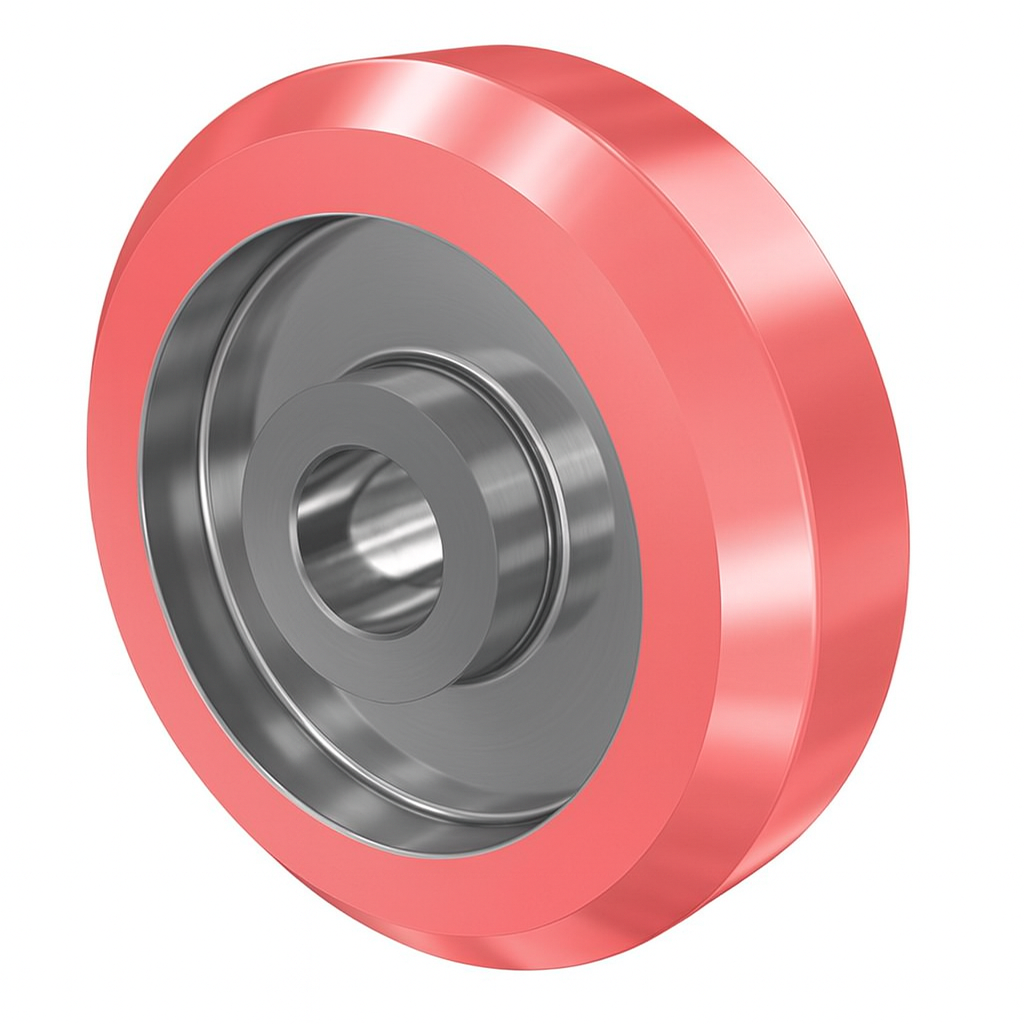

IMPROVED TOOL LIFE

T6225 provided process security, whiledemonstrating no edge chipping or fracture after completing 250 parts required.

| Industry | Engineering |

| Component | Ring |

| Material ISO code | M – Stainless steel |

| Work material | SUS304 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | T6200 |

| TSR No. | 5336T |

IMPROVED TOOL LIFE

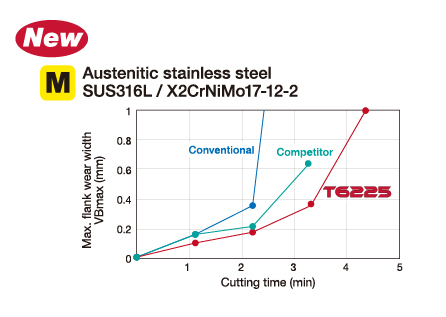

T6225 achieved double tool life thanks to its superior wear resistance.

| Industry | Engineering |

| Component | Machine Parts |

| Material ISO code | M – Stainless steel |

| Work material | SUS316L / X2CrNiMo17-12-3 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | T6200 |

| TSR No. | 5337T |