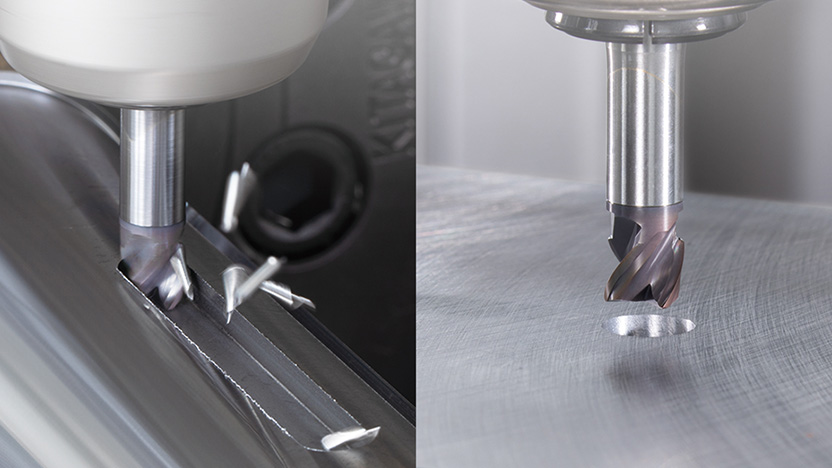

Iwaki, Japan – January, 2026 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungMeister series, introducing new multi-functional exchangeable heads designed to improve chip evacuation and suppress chatter vibration in keyway and pocket machining.

Challenges and Trends

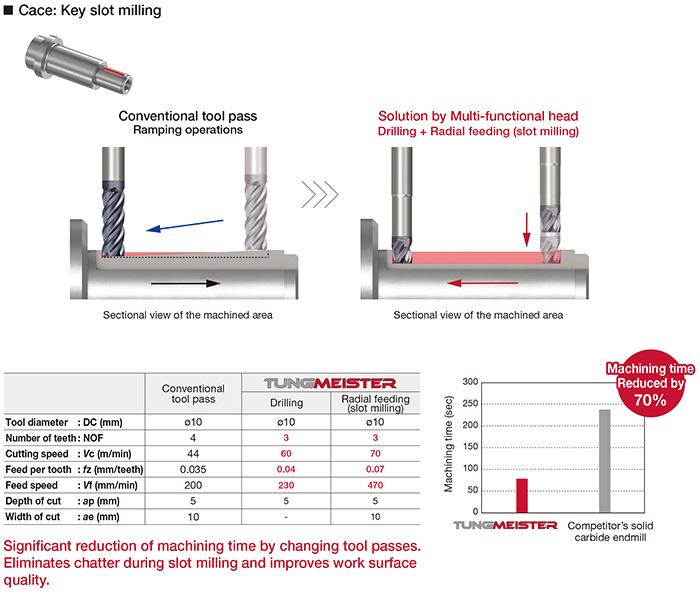

In keyway and pocket machining, solid end mills are generally used. However, since these tools do not provide sufficient drilling performance, ramping or helical milling is often employed as an alternative. As a result, problems such as poor chip evacuation and chatter tend to occur, forcing operators to reduce machining conditions. Furthermore, in today’s market environment that demands higher productivity and cost reduction, there is an increasing need for tools that can achieve more efficient and stable machining. Solving these issues and realizing high-efficiency, high-precision machining has become a major challenge on the shop floor.

Product Overview

TungMeister is Tungaloy’s high-efficiency exchangeable-head end mill series.

With over 45 head geometries and a wide variety of shank materials, it meets a broad range of machining requirements.

The simple head replacement reduces setup time while achieving high precision and productivity.

Benefits and Features

Feature 3: Excellent Chip Evacuation and Stable Machining

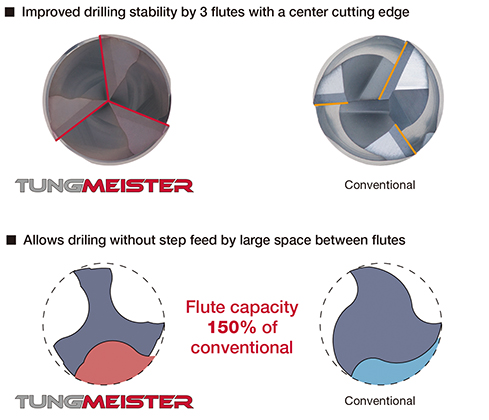

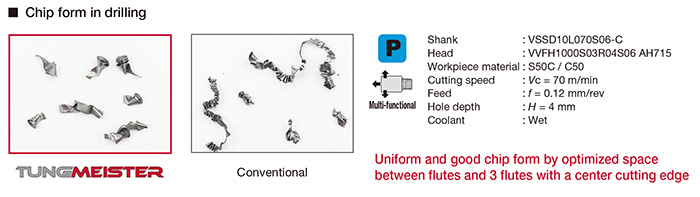

– The large chip pocket design enables efficient chip evacuation and preventing clogging.

– Cutting resistance remains stable, allowing smooth machining even in continuous operation.

– By suppressing temperature rise during cutting, the tool life is extended.