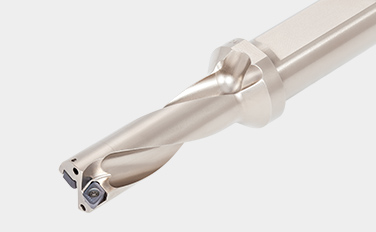

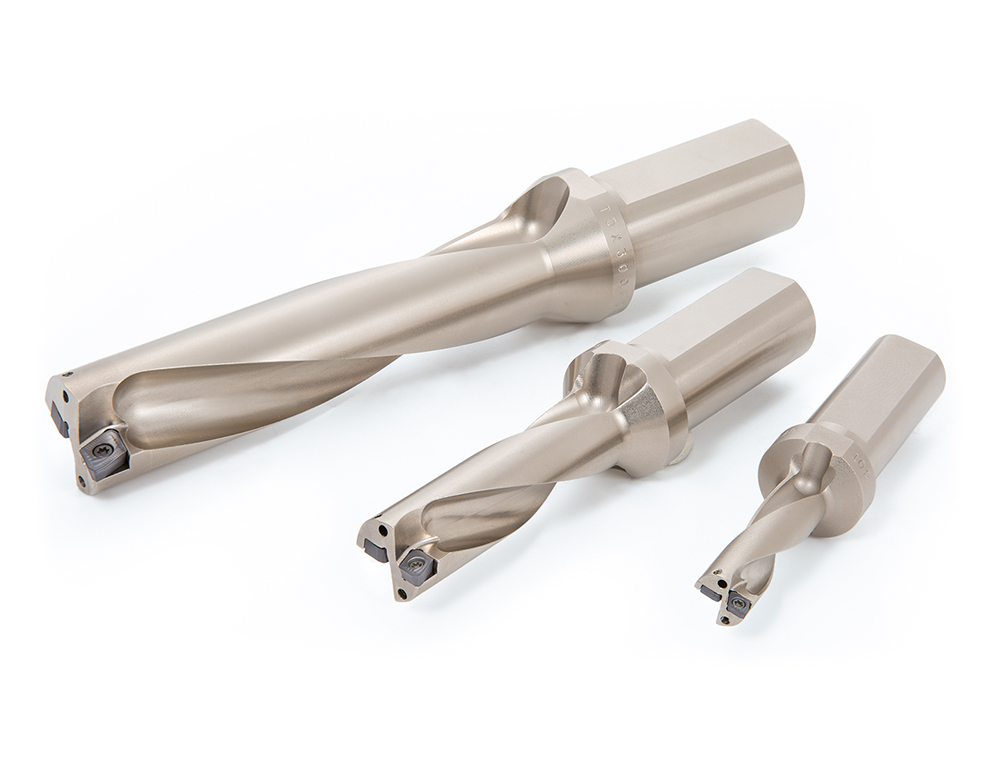

A wide range of indexable drills for various applications

Twisted coolant hole in the drill body provides excellent chip evacuation and surface finish

Applications & Features

Applications

Features

1. Rich line-up of drills and Suitable for various applications

- Drill diameter: ø12.5 – ø 54.0 mm

- L/D = 2, 3, 4, 5

A wide variety of chipbreakers and grades offers high versatility.

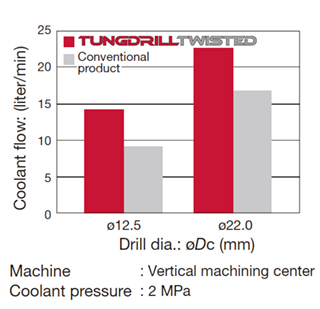

2. Excellent chip evacuation

Coolant hole increases coolant flow by 1.5 times, which improves chip evacuation, resulting in excellent surface finish.

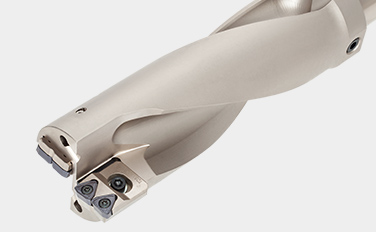

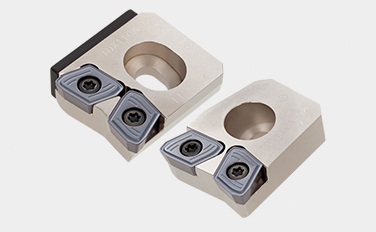

3. TungDrillBig

Drill body with adjustable cartridge covers hole diameter ranges from: øDc: ø55 mm – ø80 mm, L/D = 2.5

-

Highly rigid body and optimized insert position

Provides well balanced cutting forces and stable machining conditions for highly accurate hole making.

-

Adjustable tool diameter

TungDrillBig features 5 drill body sizes that can accommodate a range of setting plates covering a diameter range from ø55 mm – ø80 mm.

-

Variety of design options

TungDrillTwisted and TungDrill-Six type cartridges can be affixed to the same body.

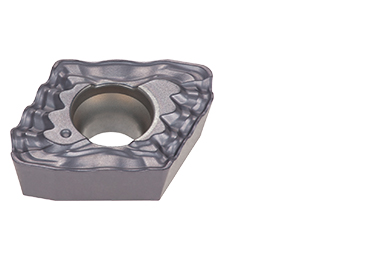

Inserts & Grades

Inserts

Main Grades

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

T1115

![]()

- K10 – K25

- High wear resistance

- Suitable for milling cast iron

AH7020

![]()

![]()

- Wear-resistant grade that enables high speed machining in steel and cast iron. Improved machining efficiency with no compromise on tool life.

AH7030

![]()

![]()

![]()

![]()

![]()

- First-choice grade in all material groups.Extremely fracture resistant, the grade provides predictability in unstable drilling applications that might, otherwise, induce edge chipping.

AH6030

![]()

![]()

- M25 – M35 / S15 – S30

- High fracture resistance

- Suitable for drilling stainless steel and heat-resistant alloy under general cutting conditions

AH9030

![]()

![]()

- P15 – P35 / K10 – K25

- High wear resistance

- Suitable for drilling steel and cast iron at high speed

GH130

![]()

![]()

![]()

- P25 – P40 / M25 – M40 / K25 – K40

- High chipping and fracture resistance

- Suitable for steel, stainless steel, and cast iron

Drill bodies & Related tools

Drill Bodies

TDX-F (ø12.5 – ø54 mm)

ø0.500” – ø2.125”

Indexable insert drills, Flat cotter

Practical examples

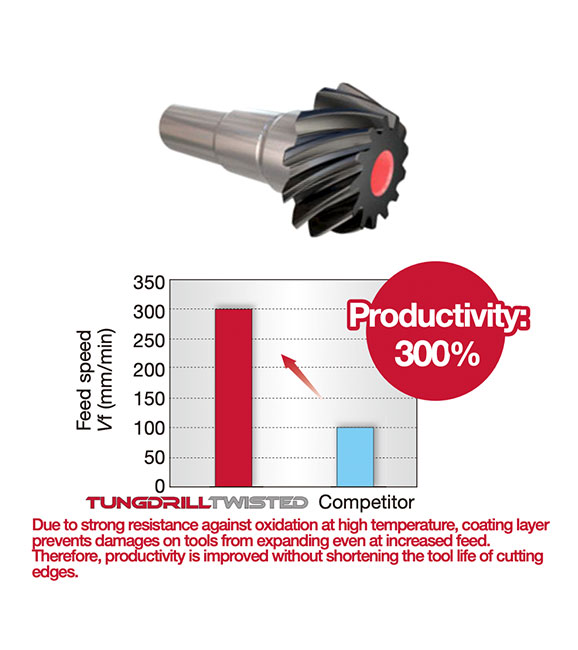

Example #1

Automotive Industry

| Part: | Pinion |

| Material: | SCM435 / 34CrMo4 |

| Drill: | TDX185F25-2 |

| Insert: | XPMT06X308R-DW |

| Grade: | AH9030 |

| Cutting conditions: | Vc = 160 (m/min) f = 0.11 (mm/rev) Vf = 300 (mm/min) H = 18 (mm) Coolant: Wet Machine: NC lathe |

Example #2

Automotive Industry

| Part: | York |

| Material: | S33C |

| Drill: | TDX200F25-3 |

| Insert: | XPMT06X308R-DJ |

| Grade: | AH725 |

| Cutting conditions: | Vc = 138 (m/min) f = 0.06 (mm/rev) Vf = 132 (mm/min) H = 25 (mm) Coolant: Wet Machine: Special-purpose machine |

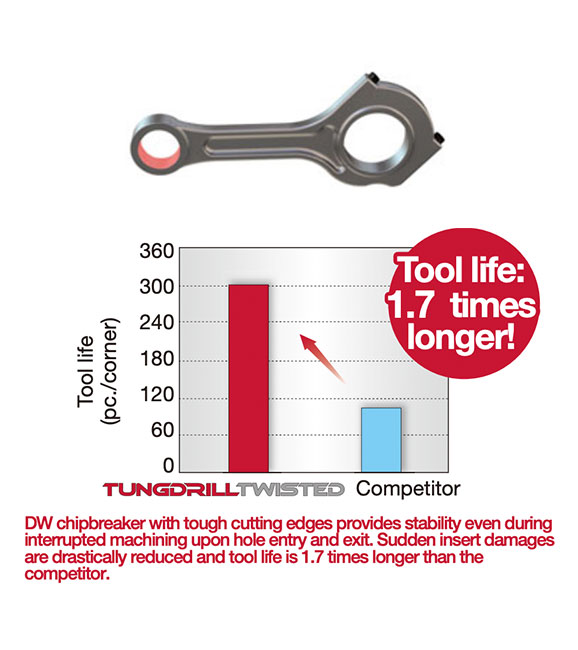

Example #3

Automotive Industry

| Part: | Connecting rod |

| Material: | S55C |

| Drill: | TDX200F25-3 |

| Insert: | XPMT06X308R-DW |

| Grade: | AH725 |

| Cutting conditions: | Vc = 90 (m/min) f = 0.06 (mm/rev) Vf = 86 (mm/min) H = 22 (mm) Coolant: Wet Machine: Special-purpose machine |

Standard cutting conditions

Recommended insert

| ISO | Workpiece material | First choice | Wear resistance | Chip control |

|---|---|---|---|---|

|

Low carbon steel (C ≤ 0.3%) | DJ AH7030 | DJ AH7020 | DW AH7030 / DG AH725 |

| Carbon steel (C > 0.3%), Low alloy steel, Alloy steel |

DJ AH7030 | DJ AH7020 | DW AH7030 | |

|

Stainless steel | DS AH7030 | DS AH7020 | DJ AH7030 |

|

Grey cast irons | DJ AH7020 | DJ T1115 | – |

| Ductile cast irons | DJ AH7030 | DJ AH7020 | – | |

|

Aluminium alloy | DJ AH725 | – | DG AH725 |

|

Heat-resistant alloys, Titanium alloys |

DJ AH7030 | DJ AH7020 | – |

|

Hardened steel | DJ AH7030 | DJ AH7020 | – |

Standard cutting conditions

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Series L/D |

Feed: f (mm/rev) | ||||

|---|---|---|---|---|---|---|---|---|---|

| ø12.5 – ø14.5 | ø15 – ø17 | ø17.5 – ø26 | ø27 – ø32 | ø33 – ø54 | |||||

|

Low carbon steels (C < 0.3) SS400, SM490, S25C, etc. st42-1, St52-3, C25, etc. |

– 200 HB | 160 – 320 | 2D, 3D | 0.02 – 0.06 | 0.02 – 0.06 | 0.04 – 0.1 | 0.04 – 0.1 | 0.04 – 0.1 |

| 4D, 5D | 0.02 – 0.06 | 0.02 – 0.06 | 0.04 – 0.1 | 0.04 – 0.1 | 0.04 – 0.1 | ||||

| Carbon steels (C > 0.3) S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 250 | 2D, 3D | 0.04 – 0.1 | 0.04 – 0.12 | 0.06 – 0.13 | 0.06 – 0.15 | 0.08 – 0.18 | |

| 4D, 5D | 0.04 – 0.08 | 0.04 – 0.08 | 0.06 – 0.1 | 0.06 – 0.12 | 0.08 – 0.14 | ||||

| Low alloy steels SCM415, etc. |

– 200 HB | 160 – 250 | 2D, 3D | 0.04 – 0.08 | 0.04 – 0.08 | 0.06 – 0.12 | 0.06 – 0.12 | 0.06 – 0.14 | |

| 4D, 5D | 0.04 – 0.08 | 0.04 – 0.08 | 0.06 – 0.12 | 0.06 – 0.12 | 0.06 – 0.14 | ||||

| Alloy steels SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 80 – 200 | 2D, 3D | 0.04 – 0.1 | 0.04 – 0.12 | 0.06 – 0.13 | 0.06 – 0.15 | 0.08 – 0.18 | |

| 4D, 5D | 0.04 – 0.08 | 0.04 – 0.08 | 0.06 – 0.1 | 0.06 – 0.12 | 0.08 – 0.14 | ||||

|

Stainless steels (Austenitic) SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 100 – 200 | 2D, 3D | 0.02 – 0.08 | 0.02 – 0.08 | 0.04 – 0.1 | 0.04 – 0.12 | 0.04 – 0.12 |

| 4D, 5D | 0.02 – 0.08 | 0.02 – 0.08 | 0.04 – 0.1 | 0.04 – 0.12 | 0.04 – 0.12 | ||||

| Stainless steels (Martensitic and ferritic) SUS430, SUS416, etc. X6Cr17, X20Cr13, etc. |

– 200 HB | 100 – 220 | 2D, 3D | 0.02 – 0.08 | 0.02 – 0.08 | 0.04 – 0.1 | 0.04 – 0.12 | 0.04 – 0.12 | |

| 4D, 5D | 0.02 – 0.08 | 0.02 – 0.08 | 0.04 – 0.1 | 0.04 – 0.12 | 0.04 – 0.12 | ||||

| Stainless steels (Precipitation hardening) SUS630, etc. X5CrNiCuNb16-4, etc. |

– | 80 – 120 | 2D, 3D | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | 0.06 – 0.1 | |

| 4D, 5D | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | 0.06 – 0.1 | ||||

|

Grey cast irons FC250, etc., 250, etc. |

150 – 250 HB | 80 – 250 | 2D, 3D | 0.06 – 0.12 | 0.06 – 0.12 | 0.06 – 0.15 | 0.06 – 0.18 | 0.08 – 0.2 |

| 4D, 5D | 0.06 – 0.1 | 0.06 – 0.1 | 0.06 – 0.12 | 0.06 – 0.14 | 0.08 – 0.16 | ||||

| Ductile cast irons FCD700, etc., 600-3, etc. |

150 – 250 HB | 80 – 200 | 2D, 3D | 0.04 – 0.12 | 0.04 – 0.12 | 0.06 – 0.15 | 0.06 – 0.18 | 0.08 – 0.2 | |

| 4D, 5D | 0.04 – 0.1 | 0.04 – 0.1 | 0.06 – 0.12 | 0.06 – 0.14 | 0.08 – 0.16 | ||||

|

Aluminium alloy A2017, ADC12, etc. AlCu4SiMg, AlSi11Cu3, etc. |

– | 200 – 400 | 2D, 3D | 0.1 – 0.12 | 0.1 – 0.15 | 0.15 – 0.2 | 0.15 – 0.2 | 0.15 – 0.25 |

| 4D, 5D | 0.08 – 0.12 | 0.08 – 0.12 | 0.12 – 0.16 | 0.12 – 0.16 | 0.12 – 0.2 | ||||

|

Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 60 | 2D, 3D | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | 0.04 – 0.1 | 0.04 – 0.1 |

| 4D, 5D | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | 0.04 – 0.1 | 0.04 – 0.1 | ||||

| Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 120 | 2D, 3D | 0.06 – 0.1 | 0.06 – 0.1 | 0.06 – 0.12 | 0.06 – 0.12 | 0.06 – 0.12 | |

| 4D, 5D | 0.06 – 0.08 | 0.06 – 0.08 | 0.06 – 0.1 | 0.06 – 0.1 | 0.06 – 0.1 | ||||

|

Hardened steel | – 50 HRC | 40 – 100 | 2D, 3D | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.1 | 0.04 – 0.1 | 0.04 – 0.1 |

| 4D, 5D | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.08 | 0.04 – 0.08 | ||||

Standard cutting conditions for DG Chipbreaker

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Series L/D |

Feed: f (mm/rev) | |

|---|---|---|---|---|---|---|

| ø27 – ø32 | ø33 – ø54 | |||||

|

Low carbon steels (C < 0.3) SS400, SM490, S25C, etc. st42-1, St52-3, C25, etc. |

– 200 HB | 60 – 180 | 2D, 3D 4D, 5D |

0.04 – 0.1 | |

For more information about this product, visit our online e-catalog or download the product report: