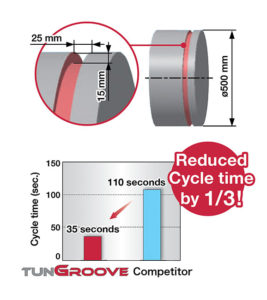

Unique system for wide grooving and wide profile grooving

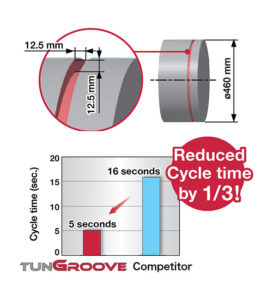

TungHeavyGroove efficiently reduces machining time on wide-width grooving and forming of complex profiles

Applications & Features

Applications

Features

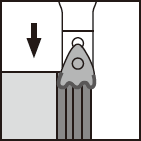

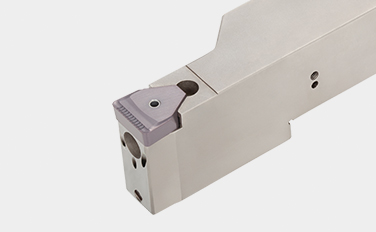

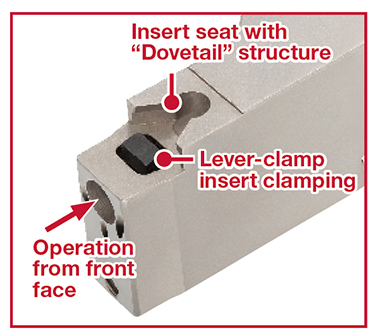

1. Easy insert clamp operated from front face

Indexing can be operated from front face of toolholder, reducing insert changing time and machine downtime.

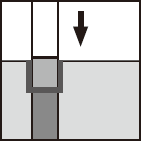

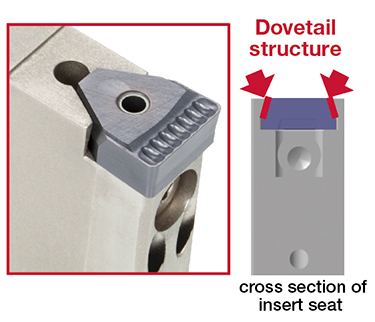

2. Highly rigid lever-clamping provides stable grooving

Dovetail structure prevents insert movement during wide grooving operations.

3. Profile grooving inserts and tools

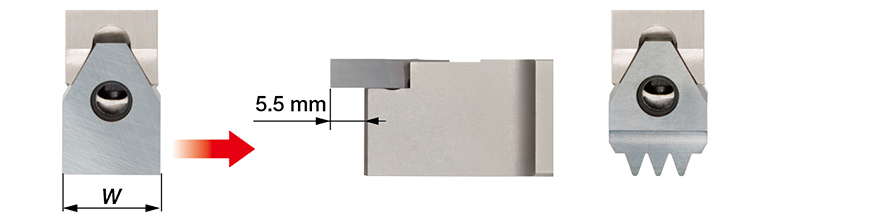

- Inserts are supplied in width (W) 10 – 25 mm.

- The insert length is extended for profile shapes up to 5.5 mm depth.

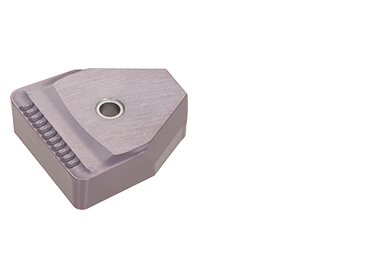

Inserts & Grades

Inserts

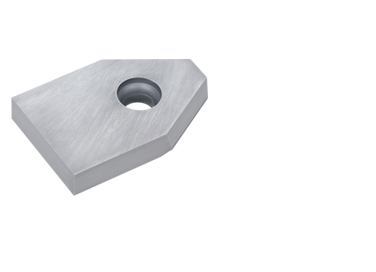

PSGM**-** (Grooving width 10 – 25 mm)

- Insert for wide grooving

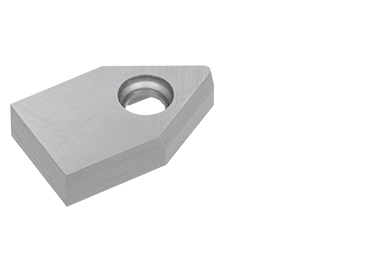

PSGB** (Grooving width 10.2 – 25.2 mm)

- Blanks for wide profile grooving (Semi-finished blanks for special shape)

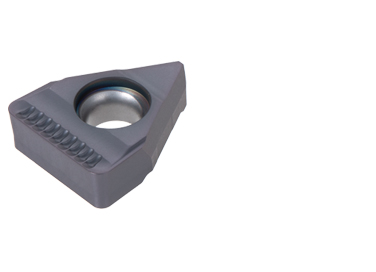

HGM** (Grooving width 10 – 25 mm)

- Insert for wide grooving

Grades

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

TH10

![]()

![]()

![]()

![]()

- P10 / M10 / K10 / N10

- Uncoated Cemented Carbide

UX30

![]()

![]()

- P30 / M30

- Uncoated Cemented Carbide

AH8015

![]()

![]()

![]()

![]()

![]()

- P10 – P20 / M10 – M20 / K10 – K25 / S10 – S20 / H10 – H20

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

- First choice for threading

T9215

![]()

![]()

![]()

- P10 – P20 / M10 – M20 / K10 – K20

- Well-balanced between wear and chipping resistance

- First choice for steel

- High versatility for a wide range of applications

Toolholders

Grooving

TungHeavyGroove Toolholders

Two styles of tools are available

- Lever lock type

- Screw on type

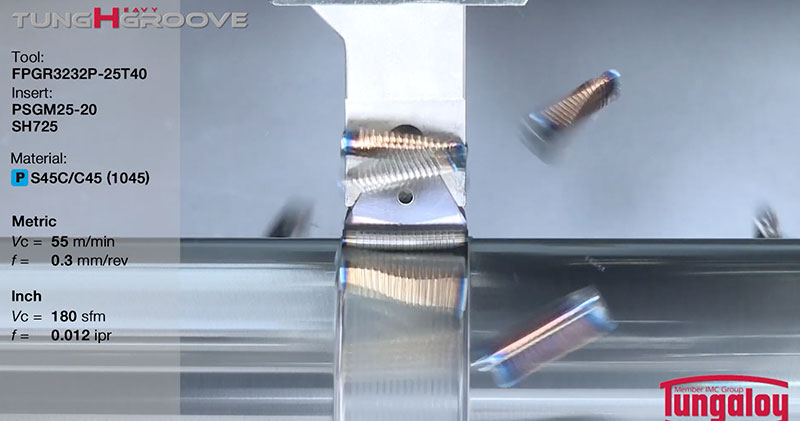

Practical examples

Example #1

Heavy Industry

| Part: | Machine part |

| Material: | SCM415 |

| Toolholder: | FPGR3232P-10T36 |

| Insert: | PSGM10-08 (W = 10 mm) |

| Grade: | AH725 |

| Cutting conditions: | Vc = 110 (m/min) f = 0.3 (mm/rev) Number of pass for 1 groove = 2 Application: Grooving Coolant: Wet |

Example #2

Heavy Industry

| Part: | Engine part |

| Material: | Cast steel |

| Toolholder: | FPGR3232P-10T36 |

| Insert: | PSGM10-08 (W = 10 mm) |

| Grade: | AH725 |

| Cutting conditions: | Vc = 65 (m/min) f = 0.37 (mm/rev) Number of pass for 1 groove = 3 Application: Grooving Coolant: Wet |

Standard cutting conditions

Wide grooving

| ISO | Workpiece materials | Hardness(HB) | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|

|

Alloy Steels SCM440, 42CrM04, etc. |

< 300 | AH725 | 50 – 180 |

| Alloy Steels SCM440, 42CrM04, etc. |

< 300 | UX30 | 50 – 120 |

Forming

| ISO | Workpiece materials | Hardness(HB) | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|

|

Steels S45C, C45, etc. |

< 200 | UX30 | 50 – 150 |

| Alloy steels SCM440, 42CrMo4, etc. |

< 300 | UX30 | 50 – 120 | |

|

Stainless steels SUS303, X10CrNiS18-9, etc. |

< 200 | UX30 | 50 – 120 |

|

Grey cast irons FC250, 250, etc. |

– | TH10 | 50 – 150 |

| Ductile cast irons FCD450, 450-10S, etc. |

– | TH10 | 50 – 120 | |

|

Aluminium alloy Si < 12%, etc. |

– | TH10 | 100 – 500 |

Wide grooving (HGM insert)

| ISO | Workpiece materials | Hardness | Priority | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|---|---|

|

Steel S45C, SCM435, etc. C45, 34CrMo4, etc. |

< 300 | First Choice | AH8015 | 80 – 180 |

| < 300 | Wear resistance | T9215 | 100 – 350 | ||

|

Stainless steel SUS303, SUS304, etc. X10CrNiS18-9, X5CrNi18-9, etc. |

< 200 | First Choice | AH8015 | 50 – 130 |

| < 200 | Wear resistance | T9215 | 100 – 250 | ||

|

Grey cast iron FC250, 250, etc. |

– | First Choice | AH8015 | 50 – 180 |

| – | Wear resistance | T9215 | 140 – 300 | ||

| Ductile cast iron FCD450, etc. 450-10S, etc. |

– | First Choice | AH8015 | 50 – 180 | |

| – | Wear resistance | T9215 | 140 – 300 | ||

|

Superalloys Inconel718, etc. |

< HRC 40 | First Choice | AH8015 | 20 – 80 |

| Titanium alloys Ti-6AL-4V, etc. |

< HRC 40 | First Choice | AH8015 | 20 – 80 |

For more information about this product, visit our online e-catalog or download the product report: