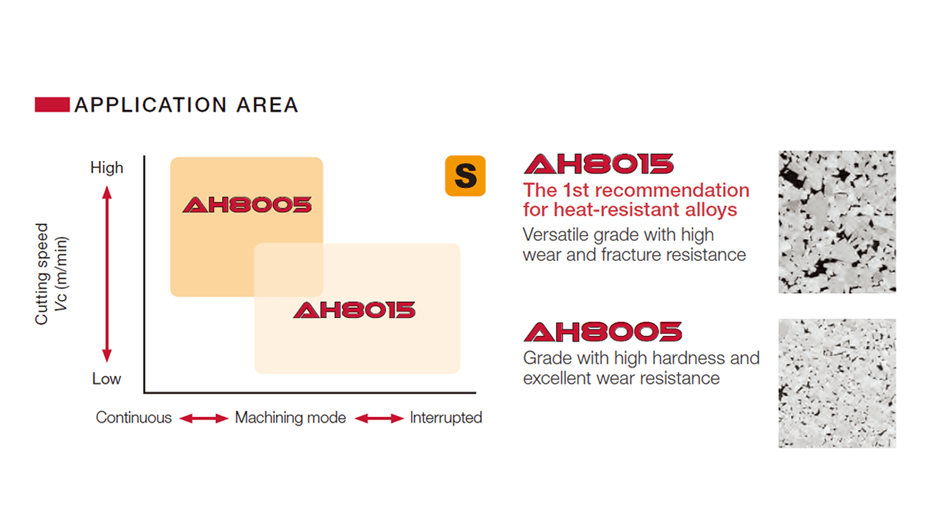

Iwaki, Japan – August, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its AH8000 series by adding 143 ISO insert items in grade AH8015, enhancing compatibility with various chipbreakers for improved performance in machining heat-resistant alloys.

Challenges and Trends

Machining of heat-resistant alloys is required in a wide range of industries, including aerospace, shipbuilding, and automotive. These applications demand cutting tools that can deliver stable performance even under high-temperature conditions. In particular, components such as shafts, turbochargers, and cylinder covers require superior wear resistance and reliability. However, with the existing AH8015 grade, standard items have not been available for certain chipbreaker types, which has led some users to abandon its adoption. To address these challenges and market conditions, there is a strong demand for an expanded lineup.

Product Overview

The AH8000 series, specialized for machining difficult-to-cut materials such as heat-resistant alloys, features the world’s first high-aluminum-content PVD coating.

This innovative coating provides an exceptional balance of wear resistance and fracture toughness, delivering long tool life and stable machining performance even under the most demanding conditions.

Benefits and Features

Excellent Wear Resistance and Long Tool Life with High-Aluminum Multilayer Coating

-The AH8015 grade utilizes a multilayer coating with a high aluminum content.

-This advanced coating significantly increases surface hardness, effectively suppressing tool wear.

-It also helps to prevent the propagation of microcracks, reducing the risk of sudden tool breakage during machining and ensuring stable, extended tool life.

Superior Chip Control and Machining Stability Across a Wide Range of Cutting Conditions

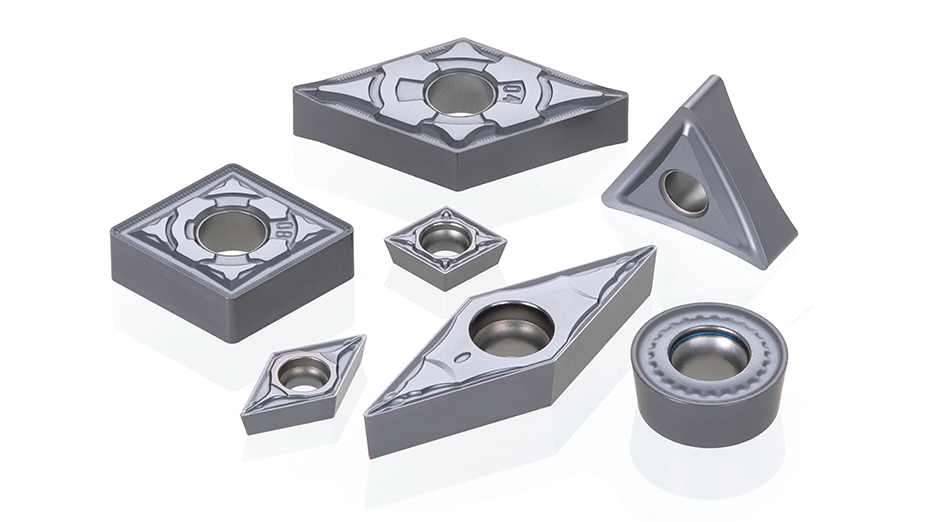

-A wide variety of chipbreaker options allows for flexible adaptation to diverse cutting conditions.

-Even in the machining of difficult-to-cut materials such as heat-resistant alloys, excellent chip evacuation minimizes machining troubles.

-By reducing fluctuations in machining load, AH8015 contributes to consistent tool life and stable machining quality.