Internal grooving and thread turning tool series for bores as small as ø5 mm

Indexable tooling solution for internal machining of small diameter bores

Applications & Features

Applications

Features

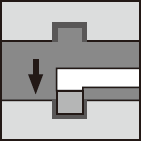

Application ranges / Internal grooving holder

Three insert geometries

Unique clamping system for highly rigid clamping

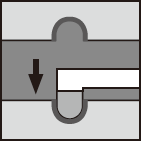

Tool body with through coolant

Make sure that, when assembling, the cutting edge is in line with the coolant outlet for effective chip evacuation.

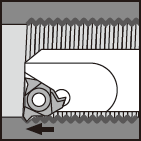

Extremely precise edge repeatability

Exchangeable head system with extremely high repeatability

Inserts & Grades

Inserts

Grades

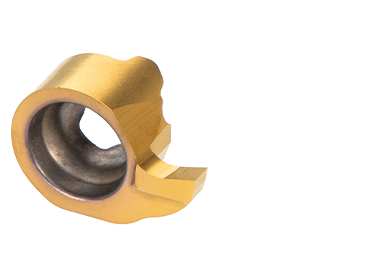

SH7025

![]()

![]()

- P20 – P30 / M20 – M30

- The latest grade with sharp cutting edge designed for small part machining.

- A combination of a columnar-structured TiCN coating and multilayered TiAlN coating provides superior surface quality and process security.

Toolholders

Sleeves

Practical examples

Example #1

| Workpiece Type: | Cover |

| Workpiece Material: | Alloy steel |

| Toolholder: | A07080-SMR4 |

| Insert: | MGR4100F000-D05 |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 38 (m/min) f = 0.01 (mm/rev) CW = 1 (mm) CDX = 0.7 (mm) Machining: Internal grooving Coolant: Wet |

Example #2

| Workpiece Type: | Valve seat |

| Workpiece Material: | Alloy steel |

| Toolholder: | A07080-SMR4 |

| Insert: | MGR4100F000-D05 |

| Grade: | SH7025 |

| Cutting conditions: | Vc = 50 (m/min) f = 0.01 (mm/rev) CW = 1 (mm) CDX = 0.5 (mm) Machining: Internal grooving Coolant: Wet |

Standard cutting conditions

Internal grooving

| ISO | Workpiece material | Grade | Cutting speed Vc (m/min) |

Feed:f (mm/rev) | |||

|---|---|---|---|---|---|---|---|

| RE = 0mm | RE = 0.03mm | RE = 0.1mm | RE = 0.2mm | ||||

|

Low carbon steel S15C, etc., C15E4, etc. |

SH7025 | 10 – 100 | 0.005 – 0.015 | 0.005 – 0.02 | 0.01 – 0.02 | 0.01 – 0.03 |

| Carbon steels, Alloy steel S55C, SCM440, etc., C55, 42CrMoS4, etc |

SH7025 | 10 – 60 | 0.005 – 0.01 | 0.005 – 0.015 | 0.005 – 0.015 | 0.01 – 0.03 | |

| Prehardened steel NAK80, PX5, etc. |

SH7025 | 10 – 40 | 0.005 – 0.008 | 0.005 – 0.01 | 0.005 – 0.01 | 0.01 – 0.025 | |

|

Stainless steel SUS304, etc., X5CrNi18-9, etc. |

SH7025 | 10 – 80 | 0.005 – 0.008 | 0.005 – 0.01 | 0.005 – 0.015 | 0.01 – 0.02 |

Profiling – full radius

| ISO | Workpiece material | Grade | Cutting speed Vc (m/min) |

Feed:f (mm/rev) | ||

|---|---|---|---|---|---|---|

| RE = 0mm (Max.ap = 0.35mm) |

RE = 0.03mm (Max.ap = 0.5mm) |

RE = 0.2mm (Max.ap = 0.7mm) |

||||

|

Low carbon steel S15C, etc., C15E4, etc. |

SH7025 | 10 – 120 | 0.005 – 0.015 | 0.005 – 0.02 | 0.01 – 0.02 |

| Carbon steels, Alloy steel S55C, SCM440, etc., C55, 42CrMoS4, etc |

SH7025 | 10 – 100 | 0.005 – 0.01 | 0.005 – 0.018 | 0.01 – 0.015 | |

| Prehardened steel NAK80, PX5, etc. |

SH7025 | 10 – 80 | 0.005 – 0.008 | 0.005 – 0.015 | 0.005 – 0.013 | |

|

Stainless steel SUS304, etc., X5CrNi18-9, etc. |

SH7025 | 10 – 100 | 0.005 – 0.01 | 0.005 – 0.012 | 0.005 – 0.01 |

Threading

| ISO | Workpiece material | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|

|

Low carbon steel S15C, etc., C15E4, etc. |

SH7025 | 10 – 100 |

| Carbon steels, Alloy steel S55C, SCM440, etc., C55, 42CrMoS4, etc |

SH7025 | 10 – 60 | |

| Prehardened steel NAK80, PX5, etc. |

SH7025 | 10 – 40 | |

|

Stainless steel SUS304, etc., X5CrNi18-9, etc. |

SH7025 | 10 – 80 |

Recommended infeeding passes for thread pitches

| Thread pitch (mm) | Insert designation | RE (mm) | Total depth of feed | Recommended number of passes | Depth of cut per pass (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pass 1 | Pass 2 | Pass 3 | Pass 4 | Pass 5 | Pass 6 | Pass 7 | Pass 8 | Pass 9 | |||||

| 0.5 | MTR460F003-D05 | 0.03 | 0.3 | 5 | 0.08 | 0.07 | 0.06 | 0.05 | 0.04 | ||||

| 0.75 | 0.03 | 0.47 | 6 | 0.12 | 0.1 | 0.08 | 0.07 | 0.06 | 0.04 | ||||

| 1 | MTR560F007-D07 | 0.07 | 0.6 | 6 | 0.18 | 0.15 | 0.1 | 0.08 | 0.05 | 0.04 | |||

| 1.25 | 0.07 | 0.76 | 7 | 0.18 | 0.15 | 0.12 | 0.1 | 0.1 | 0.07 | 0.04 | |||

For more information about this product, visit our online e-catalog or download the product report: