Iwaki, Japan – November, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its DoFeedTri series, now featuring new bodies that allow optimal tool diameter selection tailored to specific applications, enhancing machining stability and tool life.

Challenges and Trends

In general machining and stainless steel grooving operations, if the tool diameter is too large, it may remove more material than intended—even in processes designed to leave a finishing allowance. This presents a significant issue, especially in environments where high-precision machining is required, as excessive cutting can lead to quality degradation and negatively impact subsequent processes. In the market, there is a growing demand for more flexible and application-specific tool variations. It is increasingly important to be able to select the optimal tool diameter according to the workpiece geometry and machining requirements.

Product Overview

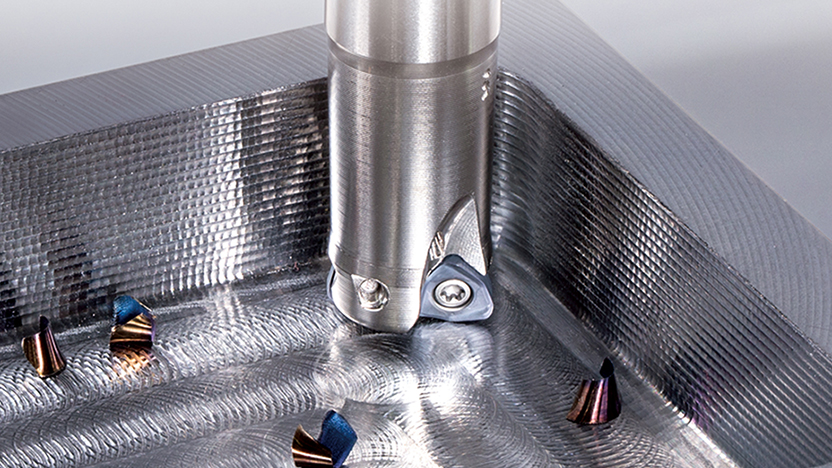

Featuring a high-rigidity design and double-sided inserts with six cutting edges, the high feed cutter “DoFeedTri” is ideal for roughing and ramping operations. It delivers both excellent cost efficiency and high machining performance, ensuring stable and highly productive machining.

Benefits and Features

Feature 1: Improved Machining Stability Through Optimal Tool Diameter Selection

– Tool diameters can be selected based on machining conditions, preventing excessive cutting loads

– Optimizing tool diameter reduces stress on the cutting edge, extending tool life

– Body selection tailored to workpiece material and machining type enhances overall stability

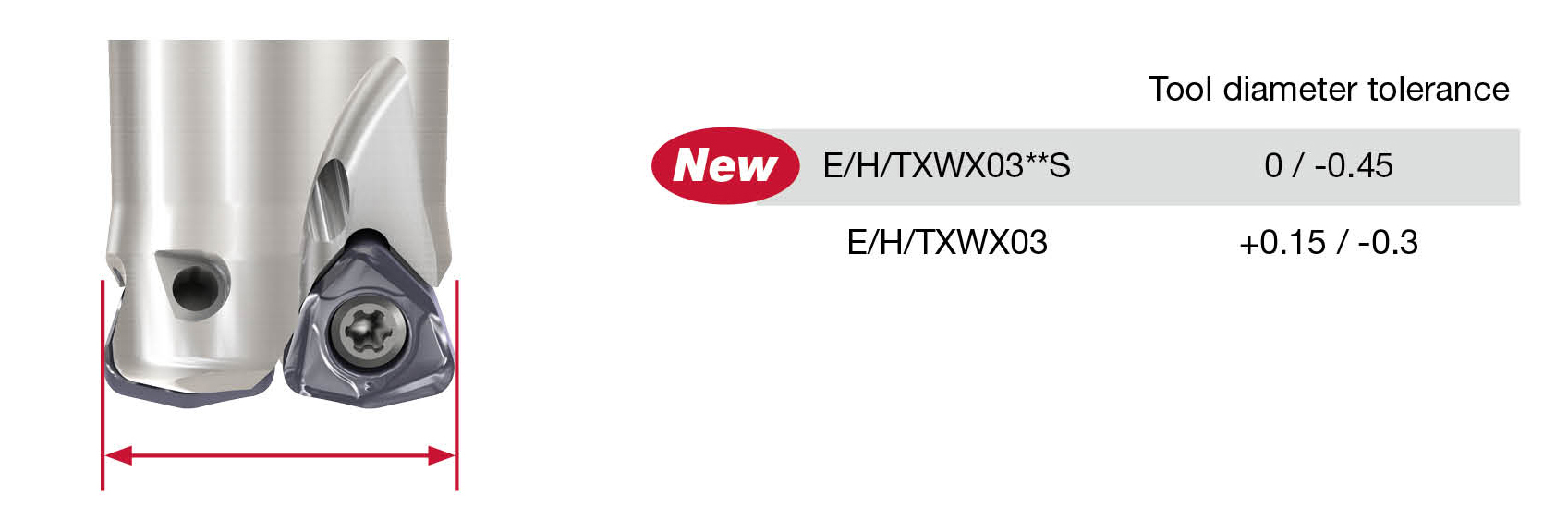

Feature 2: Design Minimizes Risk of Overcutting

– Body design based on nominal diameter helps maintain proper tool overhang

– Prevents contact with unnecessary cutting areas, preserving surface quality

– Suppresses increase in cutting resistance, reducing load on the machine

Feature 3: Versatility to Meet a Wide Range of Machining Needs

– Expanded range of tool diameters enables flexible response across various machining environments

– Tools can now be selected to meet previously unsupported machining conditions