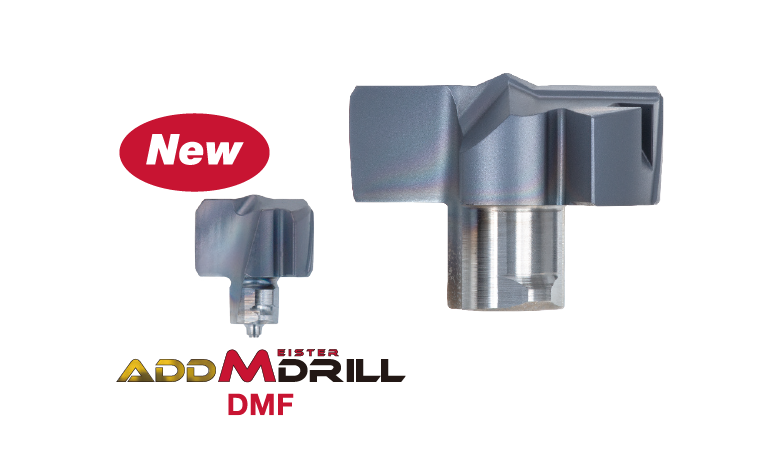

Iwaki, Japan – July, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its AddMeisterDrill series with the new DMF drill head, enabling flat-bottom hole machining in small diameters from 4 mm to 5.9 mm in a single, high-precision process.

Challenges and Trends

In the machining of components such as sleeves and small valve parts used in automatic and compact lathes, there is often a demand for flat-bottom holes. Traditionally, this required drilling with a drill that has a pointed tip, followed by a separate finishing process using an end mill to flatten the hole bottom. This not only increased the number of machining steps but also required multiple tools. Additionally, when creating tap holes for M5–M6 class threads, it is challenging to ensure sufficient hole depth with high accuracy due to the limited wall thickness of the parts. Balancing machinability and quality under these conditions has been a persistent issue. These market demands call for more efficient and precise solutions.

Product Overview

AddMeisterDrill/DrillMeister is a drill featuring an exchangeable head system that combines high machining performance with long tool life. With a wide variety of heads available, it supports a broad range of drilling applications. The simple head replacement significantly reduces setup time. Suitable for small to medium diameters, it enhances both productivity and cost-efficiency.

Benefits and Features

Feature 1: Flat-bottom hole machining achievable from a minimum diameter of 4 mm

– The DMF head enables flat-bottom hole shapes even in the small-diameter range of 4 mm to 5.9 mm

– Pilot cutting edge ensures stable tool engagement, eliminating the need for a pilot hole even for depths up to 5×D

– High-precision hole diameter and bottom surface finish can be completed in a single process, allowing for process integration

Feature 2: Long tool life and high-efficiency machining with wear-resistant grade AH9130

– Features the wear-resistant coated grade AH9130 for extended tool life

– Reduces tool change frequency, minimizing machine downtime

– Unlike solid drills, the exchangeable insert design combines cost efficiency with high productivity

Feature 3: Excellent workability with an easy-to-change head mechanism

– Specialized key design allows for effortless head replacement even in tight spaces

– Significantly reduces setup time, especially in machine environments such as automatic lathes

– No re-adjustment required after head change, maintaining consistent machining quality