Iwaki, Japan – April, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its FixRMill series with new ø20 and ø25 shank types, featuring an anti-rotation mechanism and supporting economical 6- and 8-corner inserts for enhanced face milling versatility and cost efficiency.

Challenges and Market Conditions

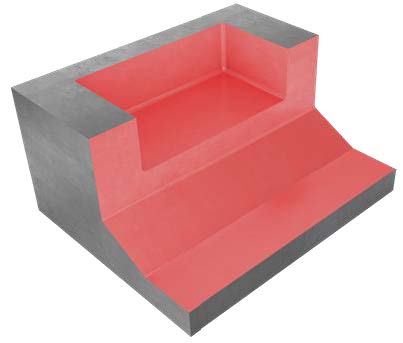

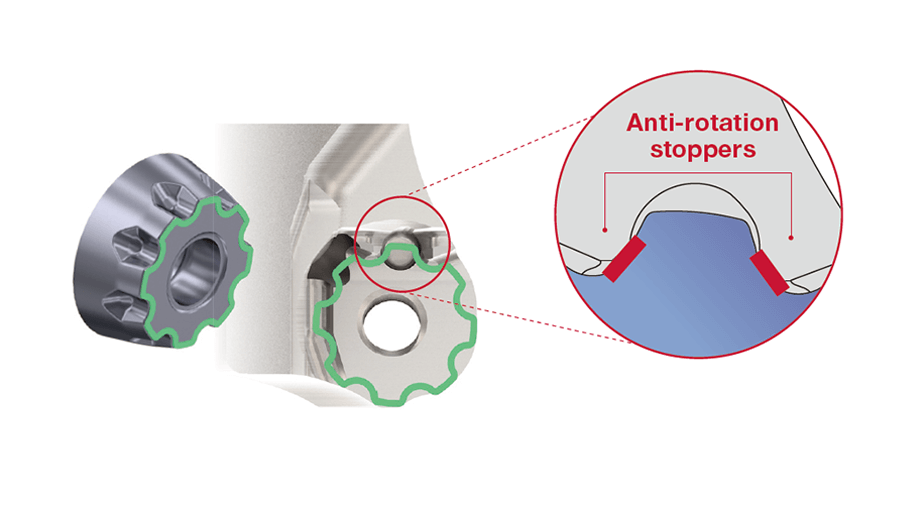

In machining applications such as mold components, generator parts, and turbine blades, efficient face milling with high depth of cut and high feed rates is essential. However, the conventional FixRMill faced issues due to its weak insert anti-rotation mechanism, which could cause the insert to move during machining, leading to damage to the tool body. This resulted in challenges regarding tool life and reliability. Additionally, the limited number of usable corners on the insert called for improvements in cost-efficiency. There is a strong demand in the market for products that can address these issues.

Product Overview

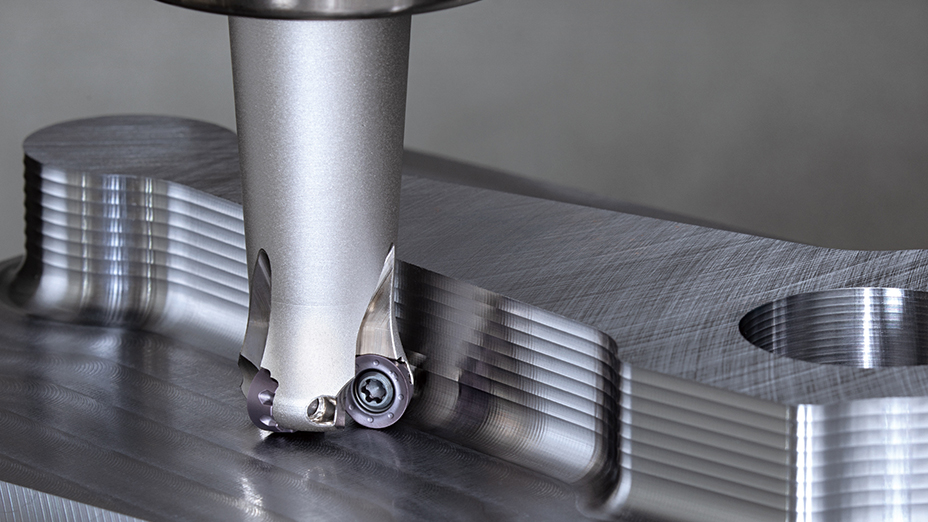

FixRMill is a high-performance end mill that achieves excellent chip evacuation thanks to its innovative flute design. Utilizing high-speed steel and powder metallurgy materials, it offers outstanding wear resistance and thermal stability, enabling high-precision machining and long tool life even under heavy-duty cutting conditions.

Benefits and Features

Feature 1: High Reliability with New Anti-Rotation Mechanism

Incorporates a new anti-rotation mechanism that securely holds the insert in place

Suppresses unexpected tool damage and ensures stable machining

Delivers high reliability across a wide range of applications, from roughing to finishing

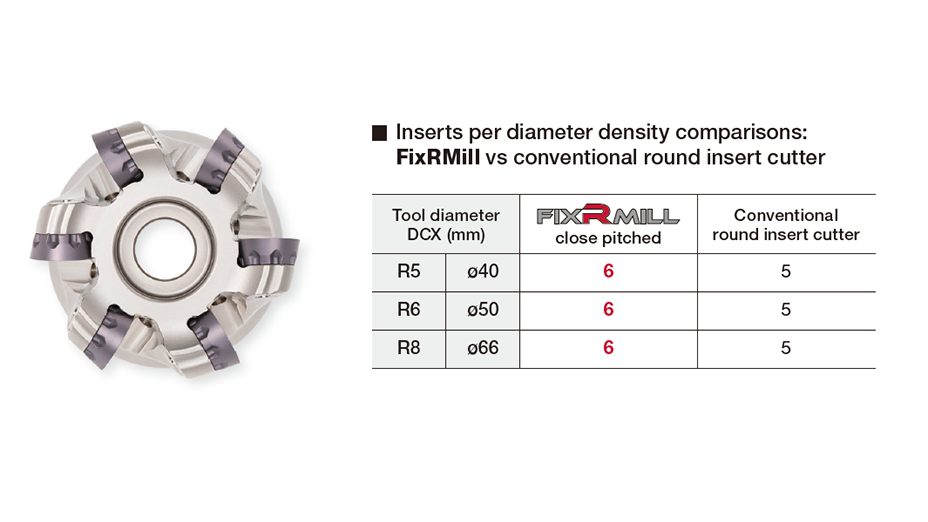

Feature 2: Economical Insert Selection

Compatible with both 6-corner and 8-corner insert types

Enables optimal insert selection based on depth of cut using the same cutter body

Maximizes the number of usable cutting edges, contributing to reduced tooling costs

Feature 3: Expanded Lineup of Small-Diameter Shank Types

Newly added ø20 and ø25 small-diameter shank versions

Suitable for compact machine tools and narrow machining areas

Greatly broadens applicability by flexibly accommodating diverse machining environments

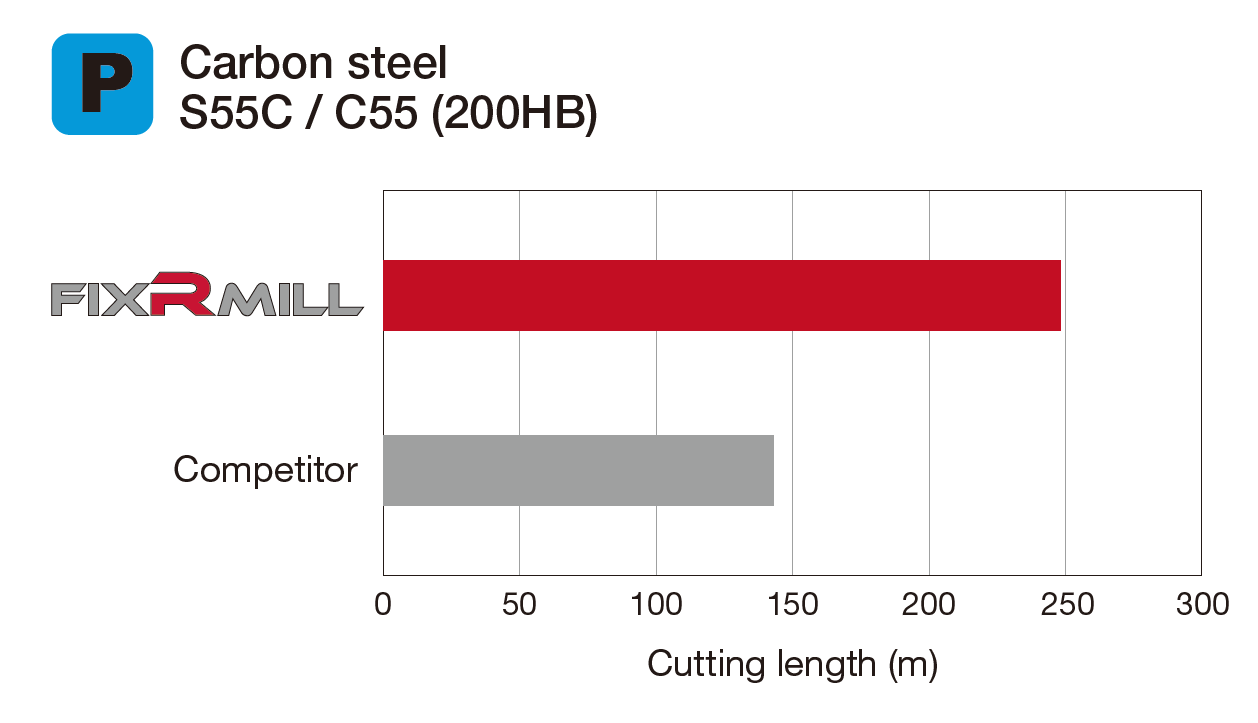

Tool Life Comparison

| Insert | RQMT10T3ENC8-MM AH3135 |

| Cutting speed | Vc = 150 m/min |

| Feed per tooth | fz = 0.6 mm/t |

| Depth of cut | ap = 1.2 mm |

| Width of cut | ap = 1.2 mm |

| Coolant | Dry |

| Overhang length | 70 mm |

| Machine | Vertical M/C, BT40 |

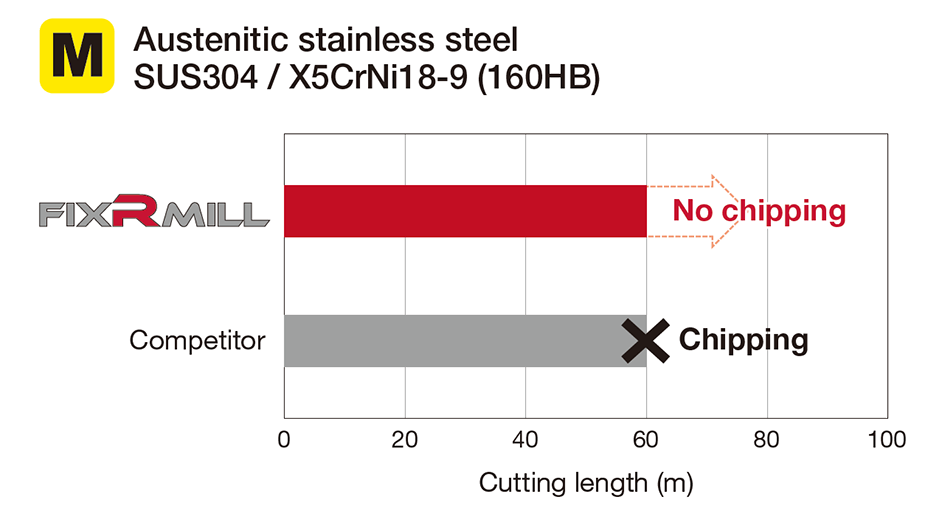

| Insert | RQMT1204ENC8-MM AH3135 |

| Cutting speed | Vc = 75 m/min |

| Feed per tooth | fz = 0.3 mm/t |

| Depth of cut | ap = 1 mm |

| Width of cut | ae = 3 mm |

| Coolant | Dry |

| Overhang length | 150 mm |

| Machine | Vertical M/C, HSK100 |

Success Stories

IMPROVED TOOL LIFE

AH3135 grade inserts featuring excellent fracture resistance achieved by nano-multi layered coating and tough substrate, new FixRMill completed one workpiece without edge chipping. In addition, the productivity increased by 1.25 times over the competitor due to increased number of cutting edges.

| Industry | Die & Mold |

| Component | Mold |

| Material ISO code | |

| Work material | C45 |

| Machine(Spindletype) | Vertical Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Toolcategory | Profiling |

| Product name | FixRMill |

| TSR No. | 1696M |