Iwaki, Japan – October, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TetraMini-Cut series, now featuring a CBN insert with a 3D chipbreaker “TCX” for stable and precise machining of hardened steel components such as gears and shafts.

Challenges and Trends

In the machining of hardened steel components such as gears and shafts, achieving high accuracy and stability in shallow groove widening operations remains a significant challenge. In particular, when using tools with a long cutting depth extension, deflection can prevent grooves from being finished to the desired width, resulting in variations in quality. Additionally, conventional tools from other manufacturers often lack CBN inserts with chipbreaker options, making it easier for chip evacuation issues to occur and leading to machining troubles. These challenges highlight the need for new solutions to address such machining requirements.

Product Overview

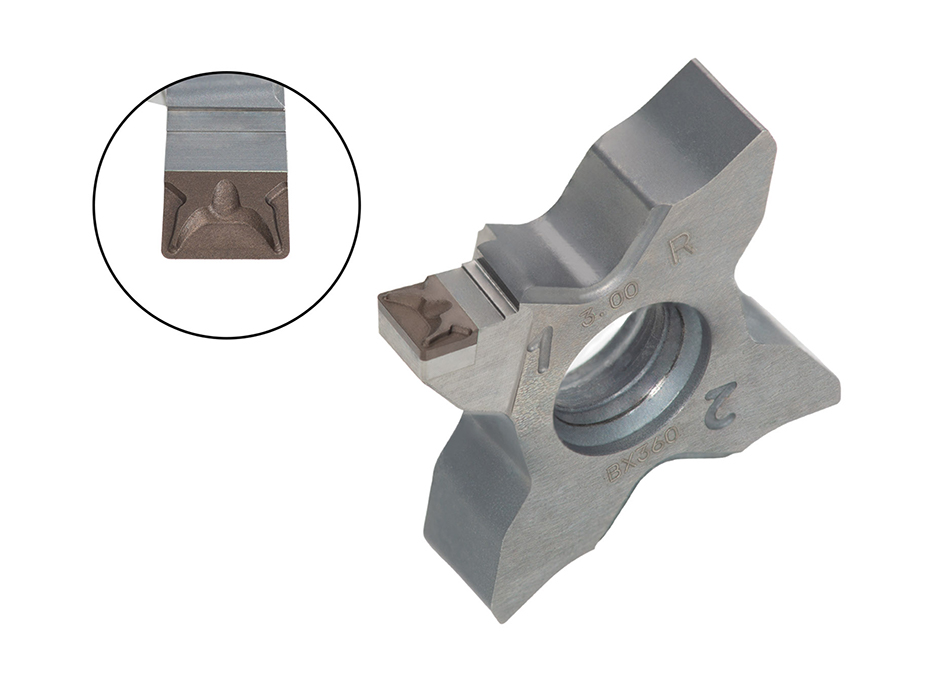

TetraMini-Cut and TetraForce-Cut are high-precision grooving and parting tools offered by Tungaloy. These tools accommodate a wide range of applications, from small components to deep groove machining. Featuring a four-corner insert design, they offer exceptional cost-efficiency while ensuring high productivity and stable machining performance.

Benefits and Features

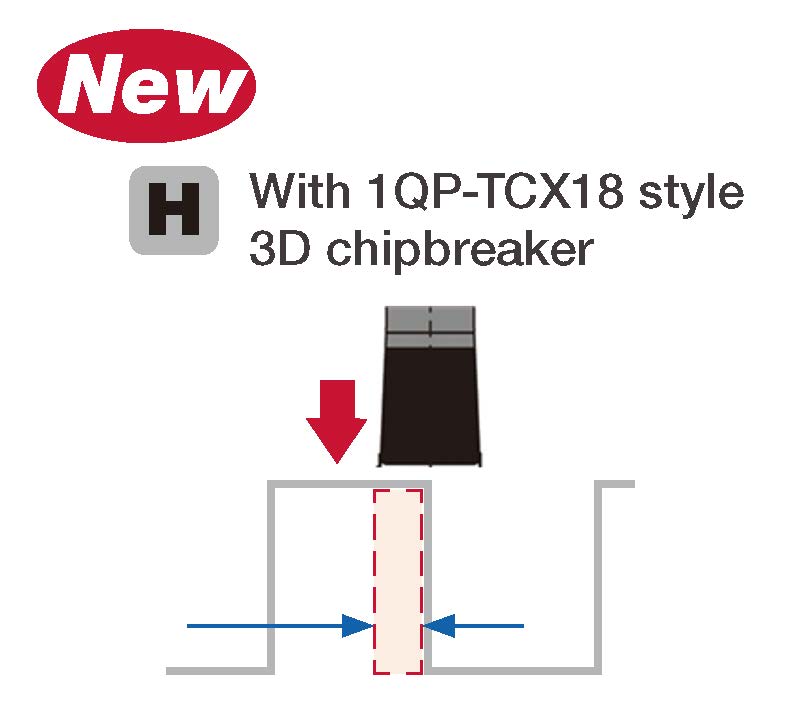

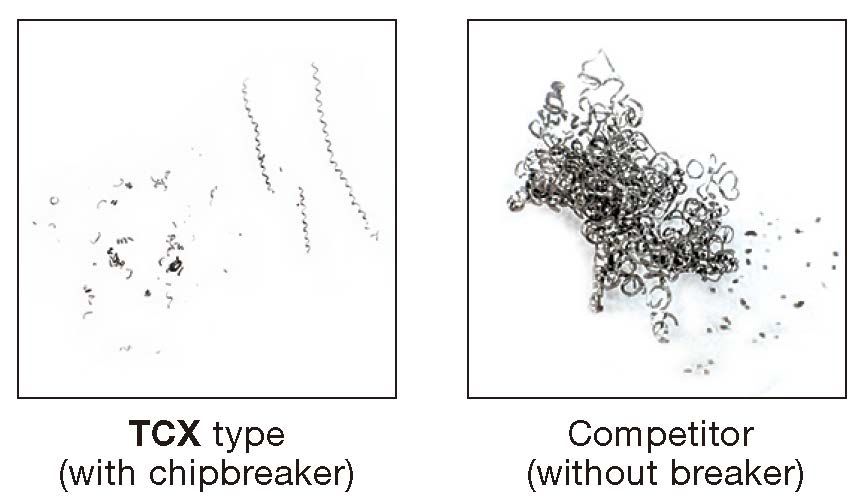

Improved Chip Evacuation with 3D Breaker

– Utilizes the same 3D chip breaker as the TungCut-CBN STX, significantly enhancing chip evacuation performance

– Prevents chip entanglement and clogging, reducing machining troubles

– Enables a stable cutting environment suitable for unmanned operation and automated production lines

High-Precision Machining through Reduced Tool Deflection

– Minimizes tool deflection during groove widening operations

– Improves cutting edge positioning accuracy, allowing for high dimensional precision

– Maintains stable machining quality even with hard-to-cut materials and high-hardness workpieces

Extensive Lineup and Unique Size Offerings

– Available in six sizes ranging from CW = 1 mm to 3 mm to meet diverse machining needs

– Introduces a unique CW = 1 mm size not offered by competitors, supporting ultra-fine grooving applications

– Covers narrow-width machining areas that were previously unsupported by TungCut, expanding the range of applications

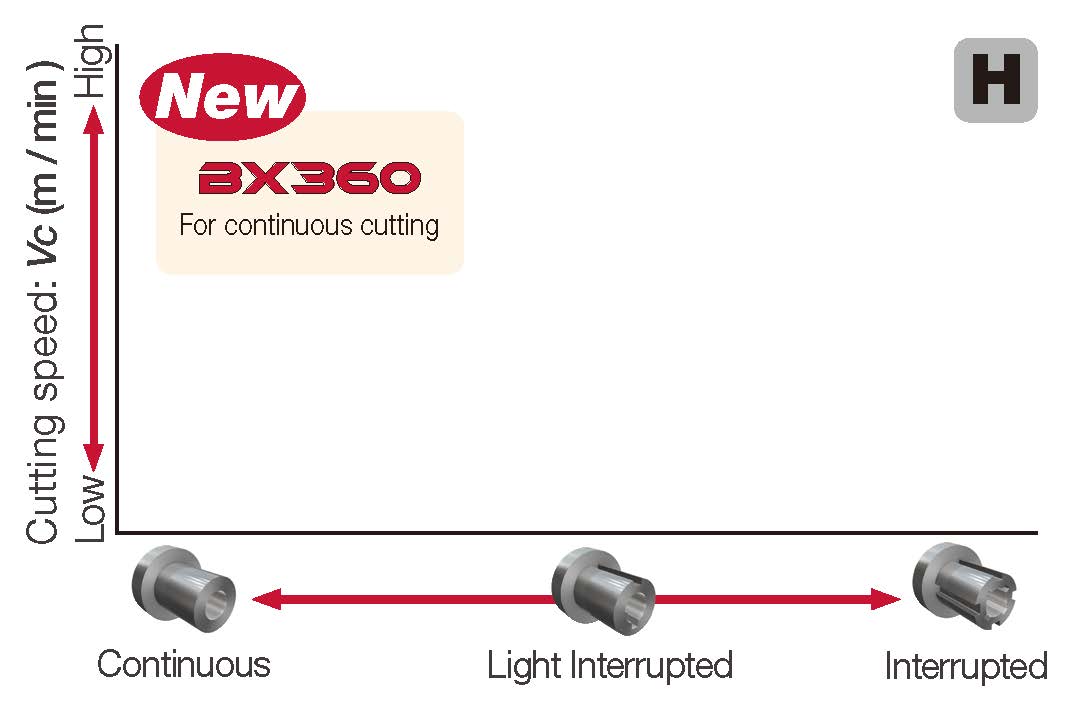

Cutting Performance

| Toolholder | STCL2525Z18 |

| Insert | 1QP-TCX18L200-020 BX360 |

| Workpiece material | SCM415H (61HRC) |

| Cutting speed | Vc = 100 m/min |

| Feed | f = 0.05 mm/rev |

| Depth of cut | ae = 0.2 mm |

| Groove depth | 3.5 mm |

| Machining | For widening external grooves |

| Coolant | Wet |