Iwaki, Japan – September, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungForce-Rec series, now including R1 corner radius inserts to meet growing machining demands with enhanced flexibility and high process reliability.

Challenges and Trends

In recent years, design requirements for the corners of components in fields such as power generation equipment, molds, automotive, and general machinery parts have been changing. In particular, alongside the previously common R0.8 and R1.6 specifications, there has been a sharp increase in demand for R1, requiring more flexible responses. As a result, there is a growing need for solutions that enable highly precise and stable R1 machining with cutting tools, making the improvement of on-site productivity and quality assurance key challenges under the current “Challenges and Market Conditions.”

Product Overview

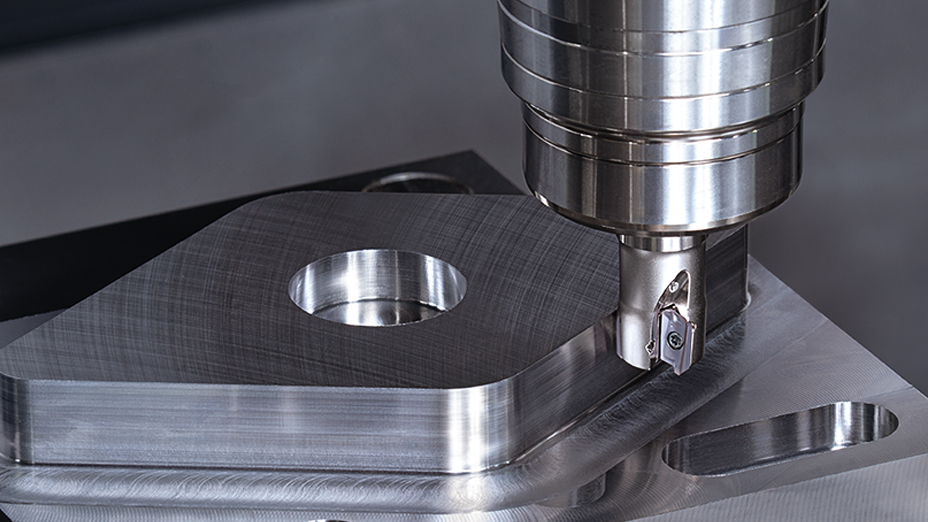

TungForce-Rec is a 90-degree shoulder milling cutter that features a unique V-bottom insert and a high-rigidity body. It delivers stable, high-efficiency machining even in small-diameter applications, offering excellent machining accuracy and productivity.

Benefits and Features

Enhanced machining versatility through the expansion of corner radius R1 inserts

– Supports multiple R sizes (R0.4, R0.8, R1, R1.2, R1.6, R2* and R3*) with the same tool body

– Allows selection of the optimal R size according to machining requirements, enabling flexible process design

– Reduces tool changeover time and contributes to shorter setup times

* Additional machining is required on the cutter body.

Improved reliability through reduced risk of insert chipping

– In cutting conditions prone to chipping with R0.8, switching to R1 provides an effective countermeasure

– A larger corner radius helps distribute cutting load, enhancing insert durability

– Maintains stable machining quality and contributes to lower defect rates