Significantly Reduce Setup Time! The New Standard “TungMeister” Surpassing HSS Centers in High-Speed Machining and Long Tool Life

For many years, machining sites have been using high-speed steel (HSS) center tools. Indeed, inexpensive and widely available HSS center drills have been a standard in many machining facilities. However, are you troubled by slow machining speeds, increased setup time due to frequent tool changes, and the burden placed on operators due to labor shortages?

Additionally, each time you regrind the tool, the tool length changes, and having to re-preset or make offsets becomes a significant burden.

Now that there is a demand for higher efficiency at the worksite, traditional methods may feel limiting. The new solution to these challenges is the TungMeister center drill head.

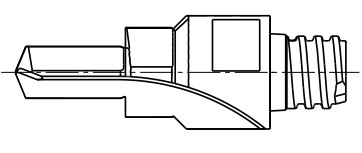

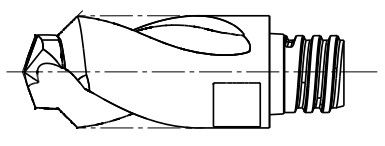

What is TungMeister? An Innovative Tool Expanding the Possibilities of Cutting

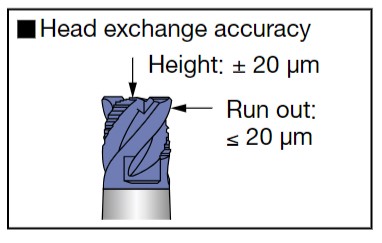

TungMeister is a head exchangeable endmill series developed by Tungaloy. Featuring flexibility through head exchange and high productivity, it can meet a wide range of machining needs.

This next-generation cutting solution provides consistently stable machining accuracy while minimizing downtime with easy tool changeovers. That’s TungMeister.

Approach to Solving Issues

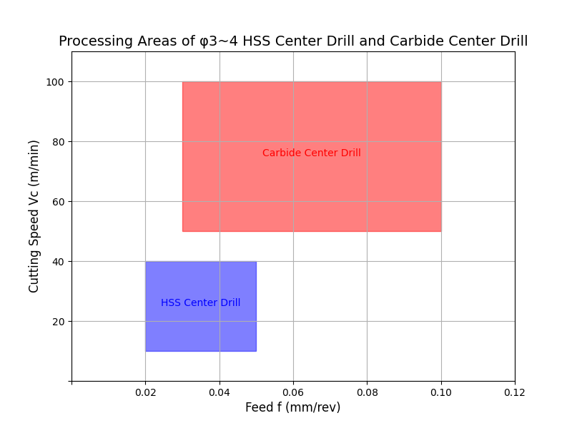

Issue 1: Slow Machining Speed

- The TungMeister center drill head, featuring a carbide coating, achieves higher cutting speeds than HSS tools. It shortens machining time and improves productivity.

Issue 2: Short Tool Life and Frequent Replacements

- The high-durability carbide coating significantly extends tool life. By reducing replacement frequency, setup time is minimized.

Issue 3: Tedious Tool Offsets Due to Regrinding

-

- Its throwaway-style head design eliminates the need for regrinding, keeping tool length constant at all times. This simplifies offset tasks and streamlines setup.

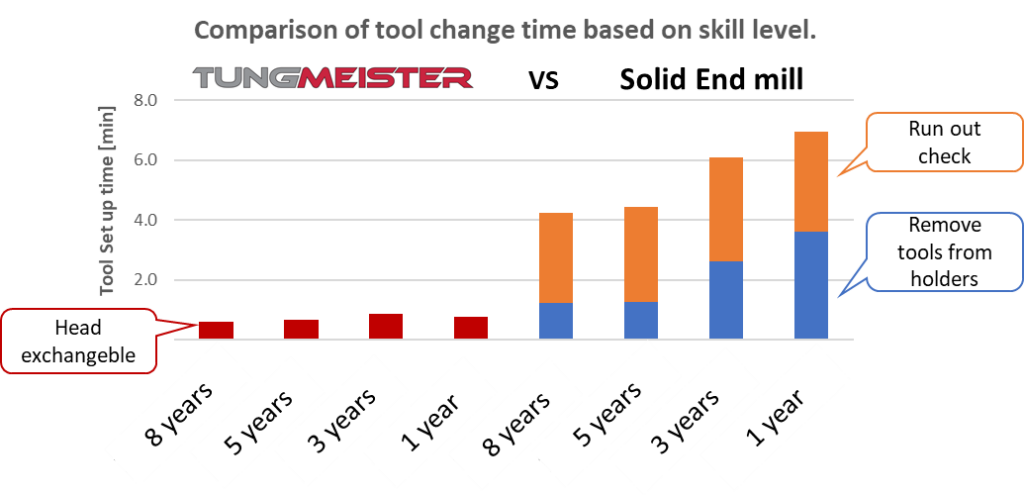

Issue 4: Burden on Operators Due to Labor Shortages

-

- Easy and quick tool changes reduce operator burden. Even with fewer personnel, you can maintain a high operating rate.

Tungaloy delivers proven custom solutions for special shapes and challenging applications.

TungMeister’s center drill heads can also accommodate special machining conditions and materials. We have already provided various custom solutions for different industries and conditions.

Proven Performance: TungMeister Success Cases on the Shop Floor

Improving Productivity

A high-speed steel (HSS) center drill currently used for center drilling on motor shafts, a type of automotive part, had the issue of slow machining time.

For new startup parts (motor shafts), we proposed and tested TungMeister.

By increasing cutting speed and feed rate, machining efficiency was improved by 4.7 times, successfully addressing the challenge of reducing machining time.

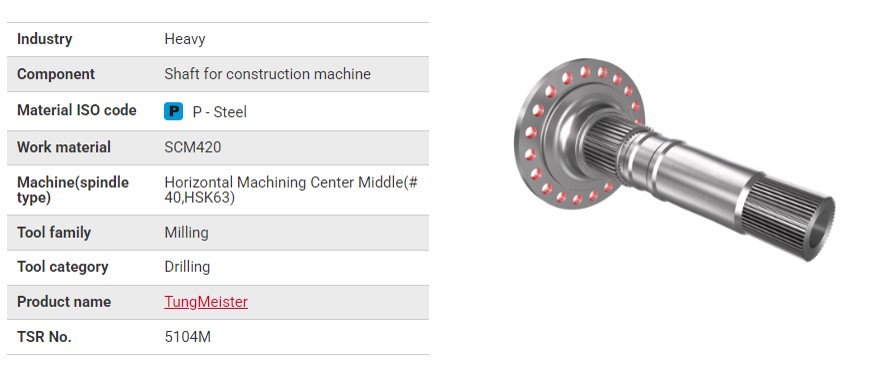

Improving Tool Life

Using the VDP head of TungMeister extended the tool life to 4.8 times that of the conventional tool.

In addition, the head-exchangeable design drastically reduced the time and effort required for tool changes.

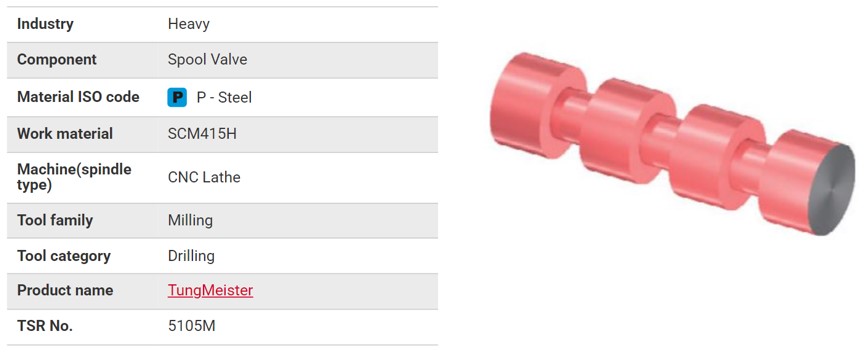

Enhancing Productivity and Tool Life

By introducing TungMeister, the conventional tool life of 100 pieces x 4 holes jumped to 600 pieces x 4 holes.

Moreover, tool change time was drastically reduced from 150 seconds for HSS to just 30 seconds for TungMeister.

Machining efficiency increased 1.3 times, making TungMeister the optimal solution.

Final Thoughts

The TungMeister center drill head solves on-site issues by improving machining speed, extending tool life, and streamlining setup.

Its design, which eliminates the need for regrinding and maintains a constant tool length, reduces operator workload and maximizes productivity.

Why not move beyond conventional HSS tools and achieve both efficiency and quality with this next-generation machining solution?

Learn more about TungMeister