Resolving Long Overhang Drill Processing Issues! Maximizing Tool Rigidity with Modular Bodies

In long overhang drill processing, the lack of tool rigidity has been a common concern in many workplaces. The necessity of using excessively long drills to avoid tool interference leads to issues such as reduced hole diameter accuracy, decreased roundness, shortened tool life, and sudden tool breakage. To mitigate these troubles, setting low cutting conditions and using high-stability HSS drills have been unavoidable, resulting in decreased productivity.

Many engineers have compromised with this situation due to the lack of alternatives.

However, with the advent of the DrillMeister modular body, a new solution is now available. This innovative solution, which maximizes tool rigidity and enhances productivity, resolves workplace concerns and opens new possibilities for machining.

Introduction to DrillMeister Modular Bodies

The DrillMeister modular body is an innovative solution for workplaces that use long drills to avoid tool interference. This modular body is compatible with commonly sold M-thread shank fastenings and can adapt to various machining conditions. By having a minimal groove length of L/D=2,3, it maximizes tool rigidity while maintaining the necessary overhang length and avoiding interference.

Tool Rigidity Maximization Solutions Using Modular Bodies

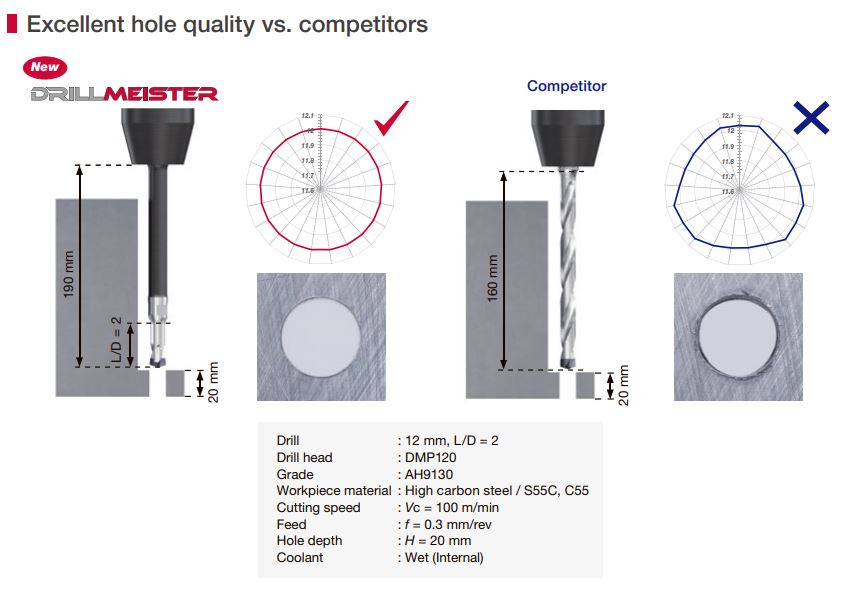

Drills require flutes to discharge chips, but these flutes can cause a reduction in tool rigidity. Therefore, in the ideal drill design, the length of the flutes should be as close as possible to the depth of the hole, and the remaining part of the tool should be a fully cylindrical section with high rigidity. This design maximizes tool rigidity, thereby improving machining accuracy and tool life. The DrillMeister modular body is designed based on this theory, making it possible to achieve maximum tool rigidity.

.

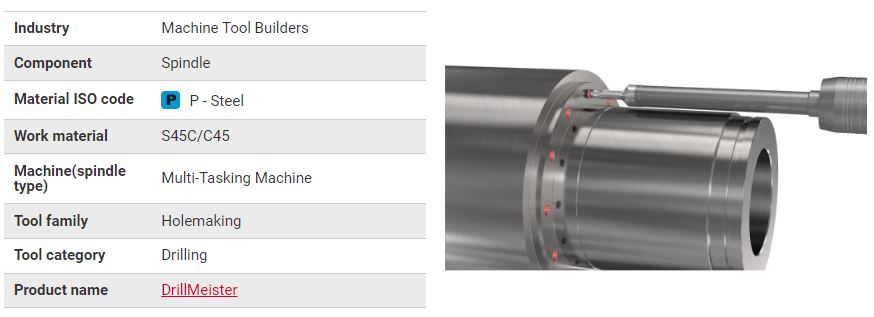

Success Story in Machine Tool Spindles

Conventional tools used HSS long drills with 20xD overhangs, but the long overhang length made machining unstable, requiring low cutting conditions.

Aiming to improve productivity, we combined the DrillMeister modular body with a 200mm carbide shank, enhancing tool rigidity while avoiding interference. As a result, machining stabilized and achieved 10 times increase in processing efficiency.

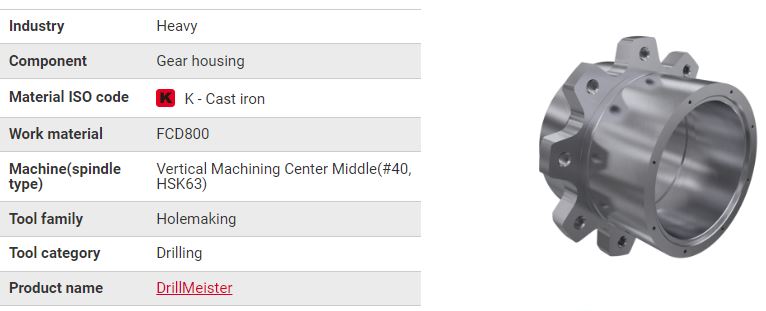

Success Story in Gear Housing

In machining bolt through-holes in cast iron gearboxes, conventional tools used a 5xD interchangeable head drill from another manufacturer, with long tools to avoid interference, which caused tool life issues. To improve machining stability and extend tool life, we proposed combining the DrillMeister modular head with a Φ20 steel shank to enhance tool rigidity. As a result,tool life extended by 1.7 times.

Conclusion

The DrillMeister modular body is an innovative solution for resolving tool rigidity issues in long overhang drill processing. By maximizing tool rigidity and enhancing machining accuracy and tool life, it significantly boosts productivity. Consider the DrillMeister modular body to resolve workplace troubles and achieve more efficient machining.