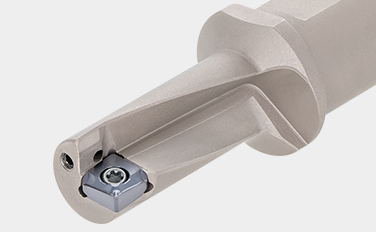

Multifunctional tool for drilling and turning

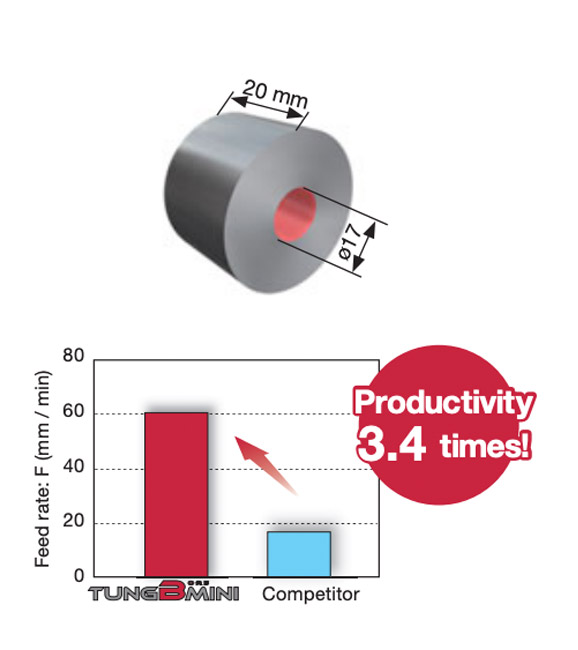

Multifunctional tool for improved productivity

Applications & Features

Applications

Features

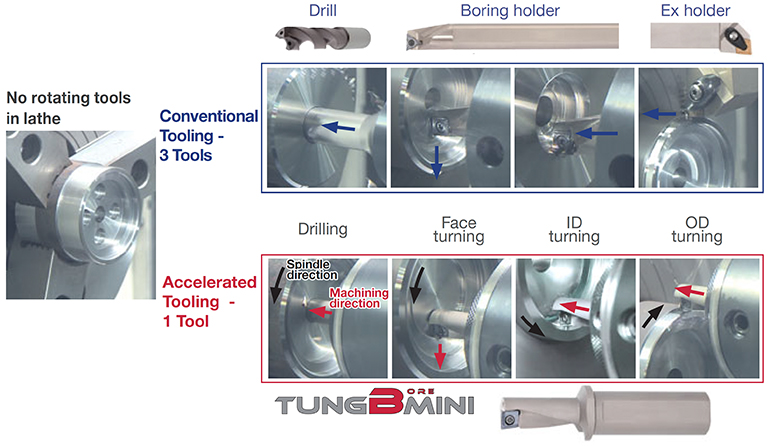

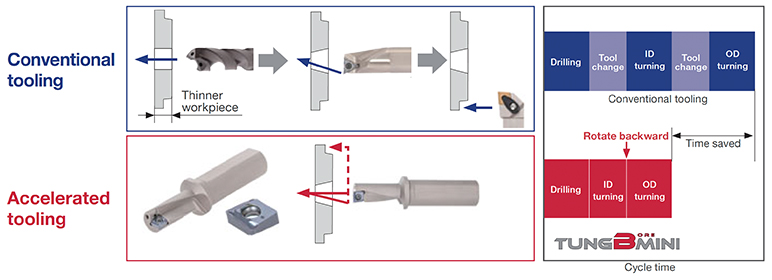

1. Minimum number of tools for maximum productivity

• A single TungBoreMini tool can handle multiple operations such as ID turning after drilling without exchanging the tools.

• Allows drilling and hole enlargement on various materials, instead of using a drill and turning tool.

• Can be used just like a standard ISO turning tool for ID, OD, and/or face turning application.

2. Reduced machine downtime

Multifunctional TungBoreMini eliminates tool changeover time, resulting in significantly reduced cycle time – this is especially effective in applications where individual processing time is short and quick, resulting in tremendous improvement in cycle time.

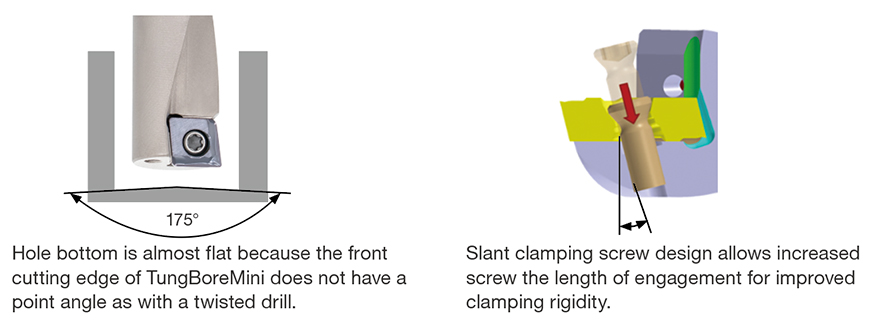

3. Features

Inserts & Grades

Inserts

Grades

AH725

![]()

![]()

![]()

![]()

- P15 – P30 / M15 – M30 / K25 – K30 / S15 – S25

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

Toolholders

External turning, Internal turning, Face turning, Hole-making

TungBoreMini Toolholders

Multifunctional tool for drilling and turning

Practical examples

Example #1

General Engineering

| Part: | Machine parts |

| Material: | SUS440 |

| Holder: | TBM12R/LF16-2.25 |

| Insert: | XOMU06H204-PS |

| Grade: | AH725 |

| Cutting conditions: | Vc = 80 (m/min) f = 0.15 (mm/rev) ap = 2.5 (mm) Coolant: Wet |

Example #2

General Engineering

| Part: | Machine parts |

| Material: | SUS304 / X5CrNi18-9 |

| Holder: | TBM12R/LF16-2.25 |

| Insert: | XOMU06H204-PS |

| Grade: | AH725 |

| Cutting conditions: | Vc = 100 (m/min) f = Drilling: 0.03, Internal turning:0.1 – 0.15 (mm/rev) ap = 0.5 (mm) Coolant: Wet |

Standard cutting conditions

Drilling

| ISO | Workpiece materials | Cutting speed Vc (m/min) | Minimum bore diameter: DMIN (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ø8 | ø10 | ø12 | ø14 | ø16 | ø18 | ø20 | ø25 | ø32 | |||

|

|

Low carbon steel Carbon steel |

50 – 180 | 0.02 – 0.05 | 0.02 – 0.05 | 0.02 – 0.07 | 0.01 – 0.075 | 0.01 – 0.08 | 0.05 – 0.13 | 0.05 – 0.13 | 0.05 – 0.14 | 0.05 – 0.14 |

|

|

Stainless steel | 50 – 160 | 0.02 – 0.05 | 0.02 – 0.05 | 0.02 – 0.07 | 0.01 – 0.075 | 0.01 – 0.08 | 0.05 – 0.13 | 0.05 – 0.13 | 0.05 – 0.14 | 0.05 – 0.14 |

|

|

Cast iron | 50 – 180 | 0.02 – 0.05 | 0.02 – 0.05 | 0.02 – 0.07 | 0.01 – 0.075 | 0.01 – 0.08 | 0.05 – 0.13 | 0.05 – 0.13 | 0.05 – 0.14 | 0.05 – 0.14 |

|

|

Aluminium alloys | 100 – 300 | 0.02 – 0.05 | 0.02 – 0.05 | 0.02 – 0.07 | 0.01 – 0.075 | 0.01 – 0.08 | 0.05 – 0.13 | 0.05 – 0.13 | 0.05 – 0.14 | 0.05 – 0.14 |

Internal turning

| ISO | Workpiece materials | Cutting speed Vc (m/min) | Minimum bore diameter: DMIN (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ø8 | ø10 | ø12 | ø14 | ø16 | ø18 | ø20 | ø25 | ø32 | |||

| Depth of cut: ap (mm) | |||||||||||

|

|

Low carbon steel Carbon steel |

50 – 180 | 0.2 – 2.5 | 0.5 – 3 | 0.5 – 3.5 | 0.5 – 4.5 | 0.5 – 5 | 0.5 – 5.5 | 0.5 – 6 | 0.5 – 6.5 | 0.5 – 7 |

| Feed: f (mm/rev) | |||||||||||

| 0.02 – 0.12 | 0.05 – 0.2 | 0.05 – 0.2 | 0.05 – 0.2 | 0.05 – 0.2 | 0.1 – 0.3 | 0.1 – 0.3 | 0.1 – 0.3 | 0.1 – 0.4 | |||

| ISO | Workpiece materials | Cutting speed Vc (m/min) | Minimum bore diameter: DMIN (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ø8 | ø10 | ø12 | ø14 | ø16 | ø18 | ø20 | ø25 | ø32 | |||

| Depth of cut: ap (mm) | |||||||||||

|

|

Stainless steel | 50 – 160 | 0.2 – 2.5 | 0.5 – 3 | 0.5 – 3.5 | 0.5 – 4.5 | 0.5 – 5 | 0.5 – 5.5 | 0.5 – 6 | 0.5 – 6.5 | 0.5 – 7 |

| Feed: f (mm/rev) | |||||||||||

| 0.02 – 0.12 | 0.05 – 0.2 | 0.05 – 0.2 | 0.05 – 0.2 | 0.05 – 0.2 | 0.1 – 0.3 | 0.1 – 0.3 | 0.1 – 0.3 | 0.1 – 0.4 | |||

| ISO | Workpiece materials | Cutting speed Vc (m/min) | Minimum bore diameter: DMIN (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ø8 | ø10 | ø12 | ø14 | ø16 | ø18 | ø20 | ø25 | ø32 | |||

| Depth of cut: ap (mm) | |||||||||||

|

|

Cast iron | 50 – 180 | 0.2 – 2.5 | 0.5 – 3 | 0.5 – 3.5 | 0.5 – 4.5 | 0.5 – 5 | 0.5 – 5.5 | 0.5 – 6 | 0.5 – 6.5 | 0.5 – 7 |

| Feed: f (mm/rev) | |||||||||||

| 0.02 – 0.12 | 0.05 – 0.2 | 0.05 – 0.2 | 0.05 – 0.2 | 0.05 – 0.2 | 0.1 – 0.3 | 0.1 – 0.3 | 0.1 – 0.3 | 0.1 – 0.4 | |||

| ISO | Workpiece materials | Cutting speed Vc (m/min) | Minimum bore diameter: DMIN (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ø8 | ø10 | ø12 | ø14 | ø16 | ø18 | ø20 | ø25 | ø32 | |||

| Depth of cut: ap (mm) | |||||||||||

|

|

Aluminium alloys | 100 – 300 | 0.2 – 2.5 | 0.5 – 3 | 0.5 – 3.5 | 0.5 – 4.5 | 0.5 – 5 | 0.5 – 5.5 | 0.5 – 6 | 0.5 – 6.5 | 0.5 – 7 |

| Feed: f (mm/rev) | |||||||||||

| 0.02 – 0.12 | 0.05 – 0.2 | 0.05 – 0.2 | 0.05 – 0.2 | 0.05 – 0.2 | 0.1 – 0.3 | 0.1 – 0.3 | 0.1 – 0.3 | 0.1 – 0.4 | |||

For more information about this product, visit our online e-catalog or download the product report: