Iwaki, Japan – November 2024 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its MillQuadFeed series to include flat-top inserts with enhanced edge strength. These new inserts come in two variations: the Z-type for versatile use and the U-type for small entry angles, offering improved durability and stable performance in challenging machining environments, such as interrupted cutting and machining of hardened materials.

Challenges and Trends

In recent years, manufacturers involved in the machining of hot forging dies, large plastic molds, and die-casting molds have been facing increasingly challenging market conditions. Particularly, during pocketing and roughing processes on workpieces where cooling holes have been pre-machined, interrupted cutting tends to occur, placing significant stress on the tools. Additionally, reworking the surfaces of forging dies for reuse requires stable machining of nitrided or work-hardened surfaces, which have become harder, further increasing the demands on the tools. To achieve stable machining under such harsh conditions, tools with high chipping resistance and superior edge strength are required. Specifically, there is a growing demand for inserts that combine high cutting performance and stability, while minimizing chipping and breakage. As a result, users are increasingly turning to high-feed cutters with heightened expectations.

Product Overview

MillQuadFeed is a cutting tool that combines low cutting resistance with high rigidity through its hybrid design, delivering exceptional reliability even in heavy-duty machining. It features a unique insert geometry that reduces cutting resistance by up to 20%, enhancing machining efficiency. Suitable for a wide range of applications such as shoulder milling and plunging, MillQuadFeed also offers double the tool life compared to conventional tools.

Benefits and Features

Feature 1: Superior Chipping Resistance with Flat-Top Inserts

– The flat-top design enhances the cutting edge, improving chipping resistance.

– Optimized negative land width and angle provide stable cutting performance.

– Reinforced corner radius ensures high durability, even in high-load machining environments such as pocket milling.

Feature 2: Inserts with Varying Entry Angles to Suit Different Applications

– By adopting the optimized insert concept of the MillQuadFeed series, the tool is flexible and adaptable to various machining operations.

– The Z type is suitable for machining where cutting depth is critical, achieving a cutting depth of APMX 1.5mm for the 09 size and APMX 2.5mm for the 15 size.

– The U type, with its small entry angle, excels in suppressing vibration during long overhang machining and extends tool life when machining high-hardness materials.

Cutting Performance

Excellent defect resistance

| Cutter | TXSW15M080B27.0R05 (ø80 mm) |

| Insert | SWMW1506USR AH3225 |

| Workpiece material | NAK80 (43.5HRC) |

| Cutting speed | Vc = 80 m/min |

| Feed per tooth | fz = 1.5 mm/t |

| Depth of cut | ap = 1.5 mm |

| Depth of width | ae = 50 mm |

| Overhang length | L/D = 3.3 |

| Number of teeth | 1 |

| Coolant | Dry |

| Machine | Vertical M/C, BT50 |

Tool life increased by 5 times during

heavy interrupted cutting of pre-hardened steel

| Cutter | TXSW15M080B27.0R05 (ø80 mm) |

| Insert | SWMW1506USR AH3225 |

| Workpiece material | SCM440 / 42CrMo4 (270HB) |

| Cutting speed | Vc = 150 m/min |

| Feed per tooth | fz = 1.5 mm/t |

| Depth of cut | ap = 1.5 mm |

| Depth of width | ae = 50 mm |

| Overhang length | L/D = 3.3 |

| Number of teeth | 1 |

| Coolant | Dry |

| Machine | Vertical M/C, BT50 |

Minimizes chip entrapment in wall processing, achieving 1.6 times longer tool life than competitors.

Success Stories

IMPROVED TOOL LIFE

The conventional product experienced breakage during processing, preventing continuation of machining. The flat-top inserts prevent chipping, achieving extended tool life.

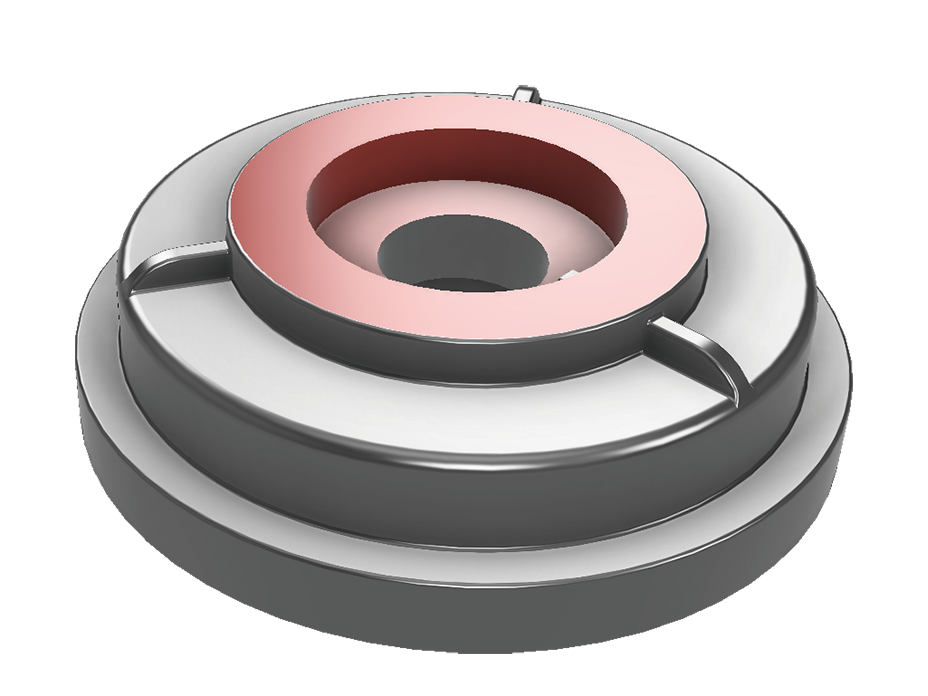

| Industry | Die & Mold |

| Component | Die casting mold |

| Material ISO code | |

| Work material | DAC(HRC40) |

| Machine(Spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | Pocketing |

| Product name | MillQuadFeed |

| TSR No. | 5064M |

IMPROVED TOOL LIFE

For machining rough, uneven cast surfaces, the flat-top inserts with high cutting edge strength achieved 1.3 times the tool life compared to conventional products. While the conventional product ended due to breakage, the flat-top inserts maintained normal wear.

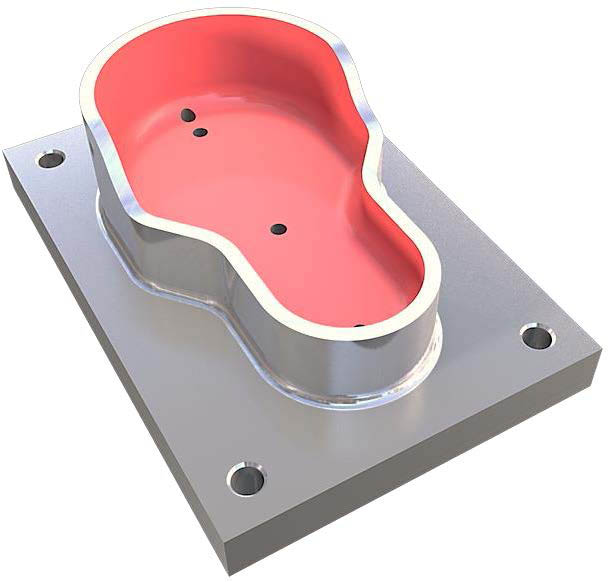

| Industry | Heavy |

| Component | Housing |

| Material ISO code | |

| Work material | FCD500 |

| Machine(Spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | Helical interpolation |

| Product name | MillQuadFeed |

| TSR No. | 5065M |