A new generation of high-feed milling cutter with versatility and long life

The unique insert design allows for changing entry angles.

The optimal depth of cut (D.O.C.) can be selected when machining various work materials.

Applications & Features

Applications

Features

1. 2 types of inserts can fit one cutter body providing two different entry angles

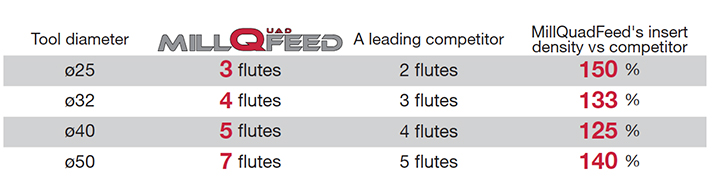

2. Close-pitch design for high efficiency

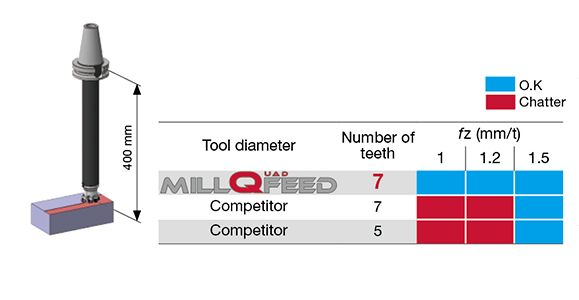

3. Superior chatter stability

Inserts & Grades

Inserts

SWMT09/15**ZER

- Max. depth of cut

– SWMT09**ZER: 1.5 mm

– SWMT15**ZER: 2.5 mm - Insert with larger cutting edge angle on the cutter body

SWMT09/15**UER

- Max. depth of cut

– SWMT09**UER: 1 mm

– SWMT15**UER: 2 mm - Insert with smaller cutting edge angle on the cutter body

- Chip thinning effect ideal for machining stainless steel and other difficult-to-cut materials

- Minimizes chatter in long overhang

SWMW**ZSR/USR

-

- Max. depth of cut

– SWMW0904ZSR: 1.5 mm

– SWMW0904USR: 1 mm

– SWMW1506USR: 2 mm

- Max. depth of cut

Main Grades

AH8015

![]()

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- First choice for machining heat-resistant alloy under general cutting conditions

AH3225

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for steel and stainless steel

AH120

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

Cutter bodies

Modular type

HXSW09 (ø22 – ø32 mm)

Modular head (TungFlex) for radius or high-feed milling

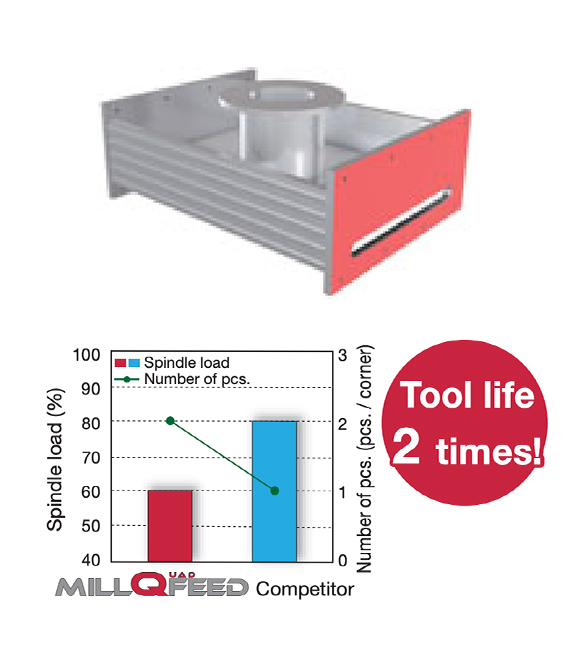

Practical examples

Example #1

Aerospace Industry

| Part: | Rod end bearing part |

| Material: | 17-4PH (PH stainless steel, 38HRC) |

| Cutter: | EXSW09M032C32.0R04 (ø32, z=4) |

| Insert: | SWMT0904UER-MM |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 200 (m/min) fz = 0.75 (mm/t) ap = 0.6 (mm) ae = 13 (mm) Application: Face milling Coolant: Wet Machine: Multi task machine |

Example #2

General Engineering

| Part: | Magnetic chuck |

| Material: | SS400 / E275A |

| Cutter: | EXSW09M025C25.0R03 (ø25, z=3) |

| Insert: | SWMT0904UER-MM |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 274 (m/min) fz = 0.83 (mm/t) ap = 0.7 (mm) ae = 25 (mm) Application: Grooving Coolant: Wet Machine: Horizontal M/C, BT50 |

Example #3

General Engineering

| Part: | Chamber |

| Material: | SUS304 / X5CrNi18-9 |

| Cutter: | TXSW15J160B50.8R08 (ø160, z=8) |

| Insert: | SWMT1506ZER-MM |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 150 (m/min) fz = 1 (mm/t) ap = 1 (mm) ae = 130 (mm) Application: Face milling Coolant: Dry Machine: Horizontal M/C, BT50, 22kW |

Standard cutting conditions

09 type

| ISO | Workpiece material | Hardness | Priority | Insert type | Grade | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|---|

| Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 300 | 0.5 – 1.5 | ||||

| Wear resistance | UER | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | ||||

| Alloy steel SCM440, etc. 42CrMo4, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.5 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.5 | ||||

| Wear resistance | UER | AH3225 | MM | 100 – 200 | 0.5 – 1.5 | ||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.2 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.2 | ||||

| Wear resistance | USR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.2 | ||||

| Austenitic stainless steel SUS304, etc. X5CrNi18-9, etc. |

– 200HB | First choice | UER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||

| Fracture resistance | UER | AH130 | MM | 100 – 150 | 0.5 – 1.2 | ||||

| Low cutting force | ZER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||||

| Precipitation hardening stainless steel SUS630, etc. X20CrNiCuNb-16-4, etc. |

28HRC – (H1150) |

First choice | UER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||

| Fracture resistance | UER | AH130 | MM | 80 – 150 | 0.3 – 1.2 | ||||

| Low cutting force | ZER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||||

| 40HRC – (H900) |

First choice | UER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | |||

| Fracture resistance | UER | AH130 | MM | 80 – 120 | 0.3 – 0.8 | ||||

| Low cutting force | ZER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | ||||

| Gray cast iron FC250, FC300, etc., 250, 300, etc. |

150 – 250HB | First choice | ZSR | AH8015 | Flat top | 100 – 300 | 0.5 – 2 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 100 – 300 | 0.5 – 2 | ||||

| Ductile cast iron FCD600, etc., 600-3, etc. |

150 – 250HB | First choice | ZSR | AH8015 | Flat top | 80 – 200 | 0.5 – 2 | ||

| Fracture resistance | ZSR | AH3225 | Flat top | 80 – 200 | 0.5 – 2 | ||||

| Titanium alloys Ti-6Al-4V, etc. |

– 40HRC | First choice | UER | AH130 | MM | 30 – 60 | 0.3 – 0.7 | ||

| Wear resistance | UER | AH8015 | MM | 30 – 60 | 0.3 – 0.7 | ||||

| Low cutting force | ZER | AH130 | MM | 30 – 60 | 0.3 – 0.7 | ||||

| Heat-resistant alloys Inconel, Hastelloy, etc. |

– 40HRC | First choice | UER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||

| Fracture resistance | USR | AH8015 | Flat top | 20 – 50 | 0.1 – 0.3 | ||||

| Low cutting force | ZER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||||

| Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | USR | AH8015 | Flat top | 80 – 130 | 0.1 – 0.3 | |

| Fracture resistance | USR | AH3225 | Flat top | 80 – 130 | 0.1 – 0.3 | ||||

| Low cutting force | ZSR | AH8015 | Flat top | 80 – 130 | 0.1 – 0.3 | ||||

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | USR | AH8015 | Flat top | 50 – 70 | 0.05 – 0.2 | ||

15 type

| ISO | Workpiece material | Hardness | Priority | Insert type | Grade | Chipbreaker | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|---|

| Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 300 | 0.5 – 1.5 | ||

| Wear resistance | ZER | AH8015 | MM | 100 – 300 | 0.5 – 1.5 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 300 | 0.5 – 2 | ||||

| Alloy steel SCM440, etc. 42CrMo4, etc. |

– 300HB | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.5 | ||

| Wear resistance | ZER | AH8015 | MM | 100 – 200 | 0.5 – 1.5 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 200 | 0.5 – 2 | ||||

| Prehardened steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | ZER | AH3225 | MM | 100 – 200 | 0.5 – 1.2 | ||

| Wear resistance | ZER | AH8015 | MM | 100 – 200 | 0.5 – 1.2 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 200 | 0.5 – 1.5 | ||||

| Austenitic stainless steel SUS304, etc., X5CrNi18-9, etc. |

– 200HB | First choice | UER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||

| Low cutting force | ZER | AH3135 | MM | 100 – 150 | 0.5 – 1.2 | ||||

| Precipitation hardening stainless steel SUS630, etc. X20CrNiCuNb-16-4, etc. |

28HRC – (H1150) |

First choice | UER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||

| Low cutting force | ZER | AH3135 | MM | 80 – 150 | 0.3 – 1.2 | ||||

| 40HRC – (H900) |

First choice | UER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | |||

| Low cutting force | ZER | AH3135 | MM | 80 – 120 | 0.3 – 0.8 | ||||

| Gray cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250HB | First choice | ZER | AH8015 | MT | 100 – 300 | 0.5 – 2 | ||

| Fracture resistance | USR | AH3225 | Flat top | 100 – 300 | 0.5 – 2 | ||||

| Low cutting force | ZER | AH8015 | MM | 100 – 300 | 0.5 – 1.5 | ||||

| Ductile cast iron FCD600, etc. 600-3, etc. |

150 – 250HB | First choice | ZER | AH8015 | MT | 80 – 200 | 0.5 – 2 | ||

| Fracture resistance | USR | AH3225 | Flat top | 80 – 200 | 0.5 – 2 | ||||

| Low cutting force | ZER | AH8015 | MM | 80 – 200 | 0.5 – 1.5 | ||||

| Titanium alloys Ti-6Al-4V, etc. |

– 40HRC | First choice | UER | AH3135 | MM | 30 – 60 | 0.3 – 0.7 | ||

| Low cutting force | ZER | AH3135 | MM | 30 – 60 | 0.3 – 0.7 | ||||

| Fracture resistance | USR | AH3225 | Flat top | 30 – 60 | 0.3 – 0.7 | ||||

| Heat-resistant alloys Inconel, Hastelloy, etc. |

– 40HRC | First choice | UER | AH3135 | MM | 20 – 50 | 0.1 – 0.3 | ||

| Wear resistance | ZER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||||

| Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50HRC | First choice | USR | AH3225 | Flat top | 80 – 130 | 0.1 – 0.3 | |

| Wear resistance | ZER | AH8015 | MM | 20 – 50 | 0.1 – 0.3 | ||||

| SKD11, etc. X153CrMoV12, etc. |

50 – 60HRC | First choice | USR | AH8015 | Flat top | 50 – 70 | 0.05 – 0.2 | ||

For more information about this product, visit our online e-catalog or download the product report: