Iwaki, Japan – October, 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungMeister series with the addition of a new torque wrench compatible with S04 size heads, ensuring consistent tightening and optimal tool performance with improved usability.

Challenges and Trends

TungMeister is a head-exchange end mill series used across a wide range of industries. In particular, industries such as automotive, construction machinery, aerospace, and heavy electrical and heavy industry have expressed a need to reduce variation in tool tightening torque due to concerns about its impact on machining quality. Furthermore, conventional torque wrenches only supported screw standards of S05 and larger, and could not accommodate tightening for the smaller S04 size. Demand is growing for new products that address these issues.

Product Overview

High-Efficiency Exchangeable-Head End Mill

TungMeister is a high-efficiency end mill system with a screw-on exchangeable head that allows for quick and easy tool changes. With over 45 head styles and a wide variety of shank materials, it meets a broad range of machining needs while delivering both high productivity and machining precision.

Benefits and Features

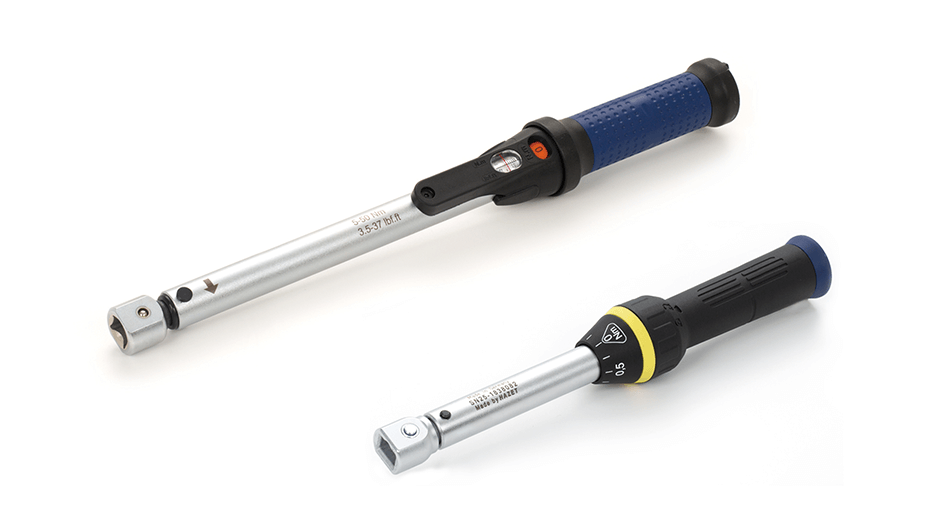

Feature 1: Torque Control Compatible with Screw Standards S04 to S08

– Newly compatible with S04 standard, enabling use with a wider range of head sizes

– Torque control ensures proper tightening torque, maximizing tool performance

– Reduces the risk of tool damage or machining defects caused by over-tightening or under-tightening

Feature 2: Excellent Operability with Compact Design

– Achieves a smaller and lighter design compared to conventional products

– Easy handling even in narrow spaces, improving work efficiency

– Reduces operator fatigue and supports stable torque management