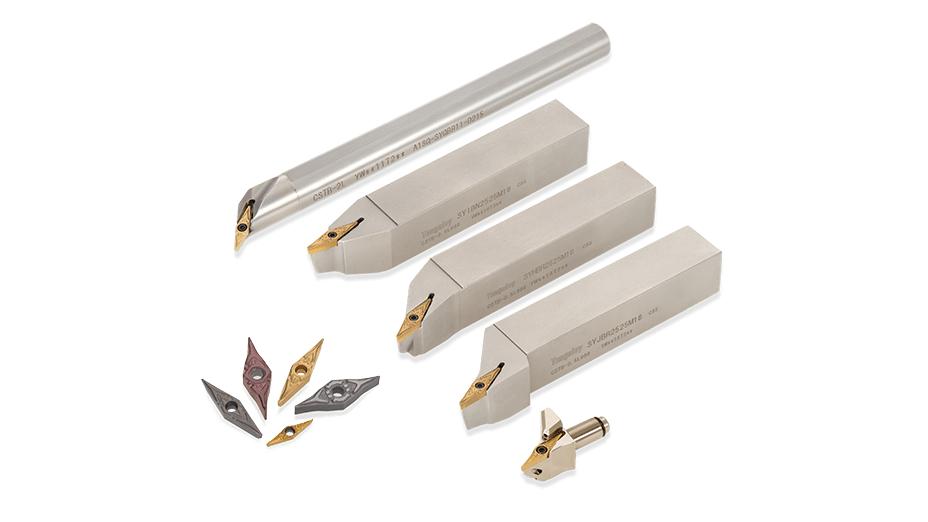

Iwaki, Japan – November 2025 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its Y-Pro Series with the addition of precision-ground YCGT inserts featuring a 25° corner angle for enhanced profiling and undercutting performance.

Challenges and Trends

In the field of small parts machining, where high-precision taper machining, profiling, and undercutting are required, improved machining accuracy and consistent surface quality are essential. This is especially true for applications such as fitting components on automatic lathes, medical implants, and shafts, where there is a growing demand for high-precision inserts with a 25° corner angle. However, suitable ground inserts optimized for this field have been limited, posing challenges in ensuring machining stability and quality under the current Challenges and Market Conditions.

Product Overview

Benefits and Features

Feature 1: Ground Insert Ideal for High-Precision Machining

– YCGT inserts deliver dimensional accuracy and edge quality comparable to grinding processes

– The 25° corner angle design enables precise machining of intricate shapes and small components

– Ensures stable machining with minimal dimensional variation in high-precision finishing operations

Feature 2: Excellent Chip Control with JS Breaker

– Unique 3D breaker geometry optimizes chip breaking and evacuation

– Performs effectively across a wide range of applications, from finishing to deep cutting

– Reduces chip entanglement and interference with the workpiece, enhancing productivity and safety

Feature 3: Stable Machining and Superior Surface Finish with SH7025 Grade

– SH7025 grade offers an ideal balance of wear resistance and toughness

– Ensures consistent tool life even during extended continuous machining

– Produces excellent surface gloss and smoothness, minimizing the need for secondary operations

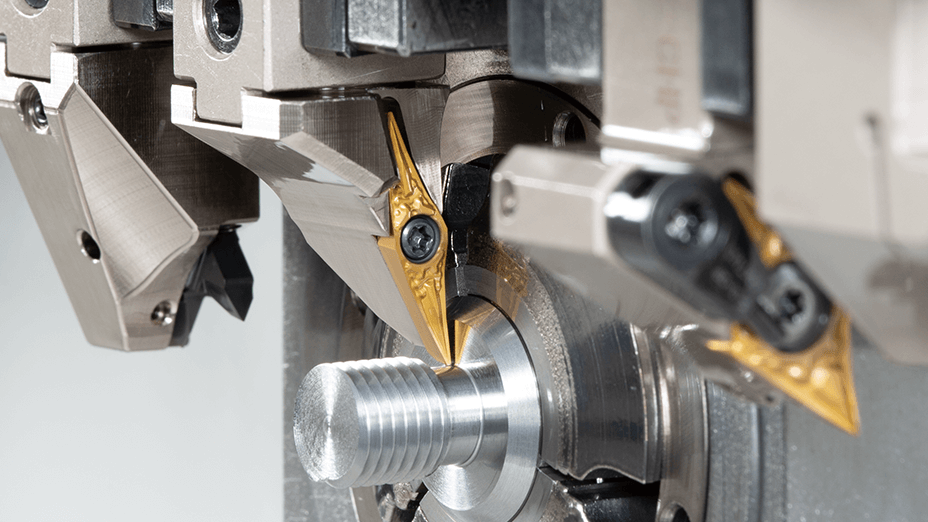

Success Stories

IMPROVED TOOL LIFE

Traditionally, machining the thread-end taper requires a dedicated insert shape. YCGT performs this operation while delivering 1.75 times longer tool life.

| Industry | Engineering |

| Component | Fitting |

| Material ISO code | |

| Work material | SUS304/X5CrNi18-10 |

| Machine(Spindletype) | CNC Lathe |

| Tool family | Turning |

| Toolcategory | External turning |

| Product name | Y-Pro Series |

| TSR No. | 5446T |

PROCESS INTEGRATION

Conventionally, two dif ferent tools were required for external turning and profiling. YCGT integrates both functions into a single tool.

| Industry | Engineering |

| Component | Shaft |

| Material ISO code | |

| Work material | S45C/C45 |

| Machine(Spindletype) | CNC Lathe |

| Tool family | Turning |

| Toolcategory | External turning |

| Product name | Y-Pro Series |

| TSR No. | 5447T |