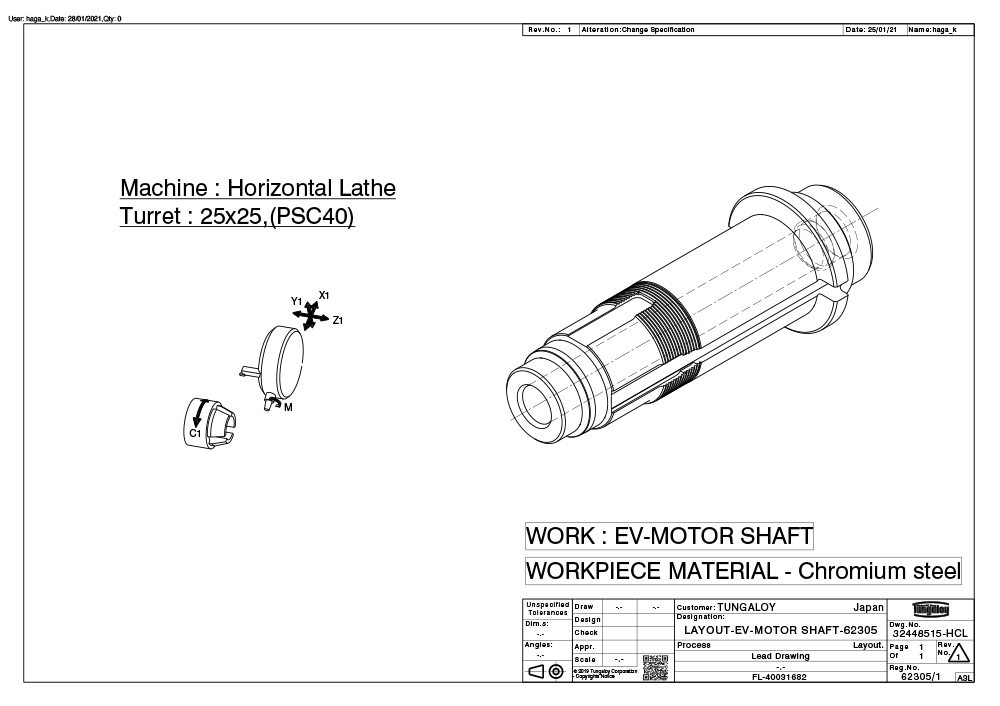

Automotive – EV Motor shaft

EV driving motors are required to have output characteristics that can exhibit performance over an entire range from low-speed to high-speed rotation, and the development of lightweight shafts with excellent dynamic balance have been developed in recent years.

Shafts are becoming hollow to reduce their weight, and it is becoming necessary to handle deep hole drilling in recent shaft operations.

Automobile shafts are made of low carbon steel, which has many chip control problems in production.

Machining process after hardening is also required in shafts, so how to achieve highly efficient and economical use of CBN inserts is also an important factor.

Tungaloy‘s unique technology provides comprehensive solutions for deep hole drilling, improving chip control and efficient use of CBN inserts.

Tooling concepts

- Provide deep hole drilling solutions with high productivity and reliability

- Improve chip control by applying holders with internal coolant

- Applying hard turning and removing grinding processes after hardening

- Minimize machine down time by applying TungCap tooling

Featured process

![]()

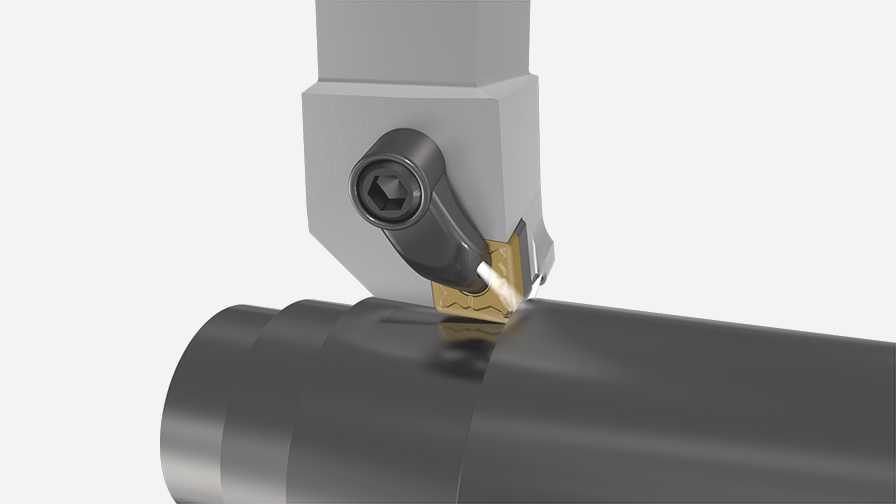

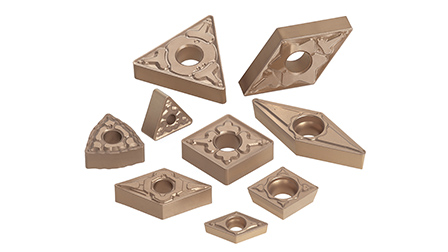

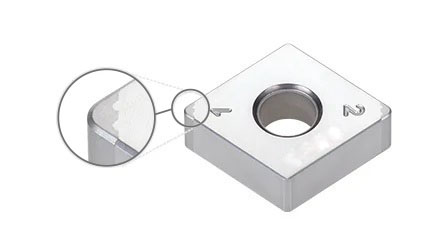

- Latest CVD coating layer provides excellent wear resistance and excellent fracture resistance

- Excellent fracture resistance, due to a new improved surface coating treatment

![]()

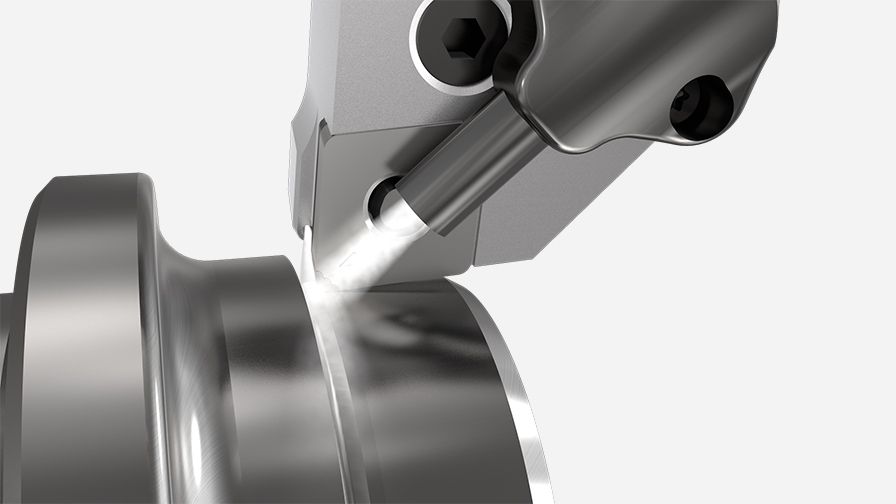

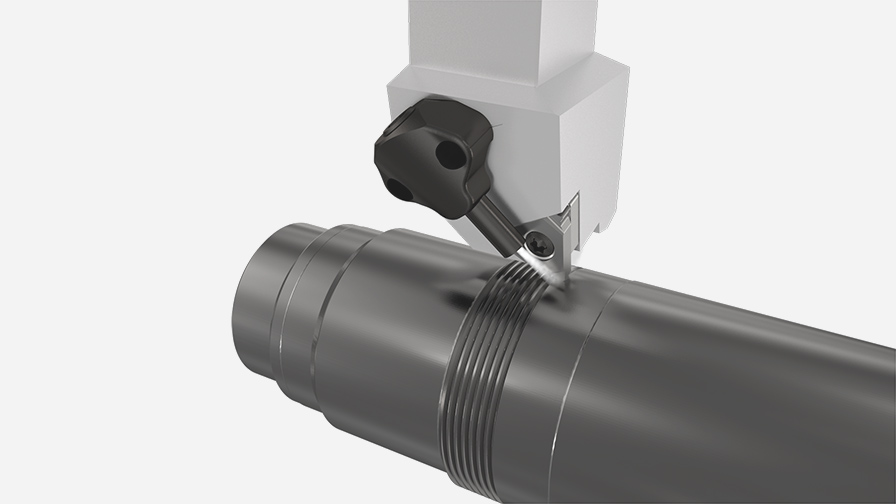

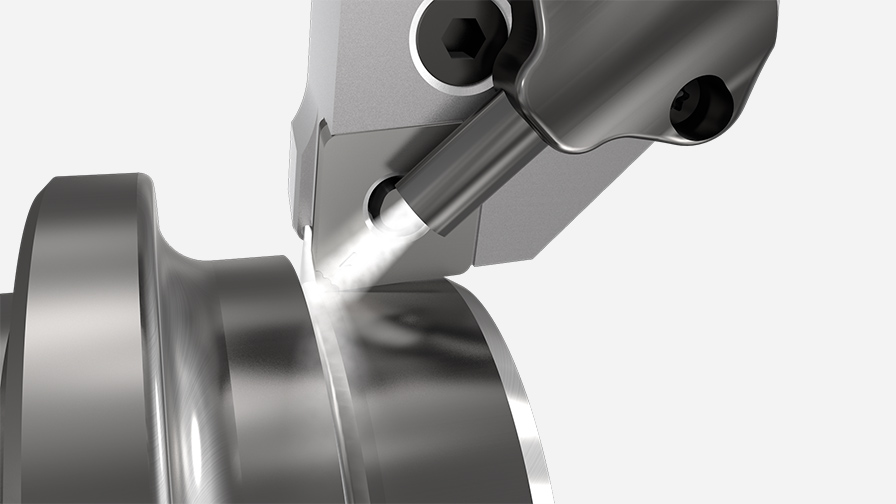

- Internal coolant toolholder series

- Optimized two streams of coolant jets to maximize productivity

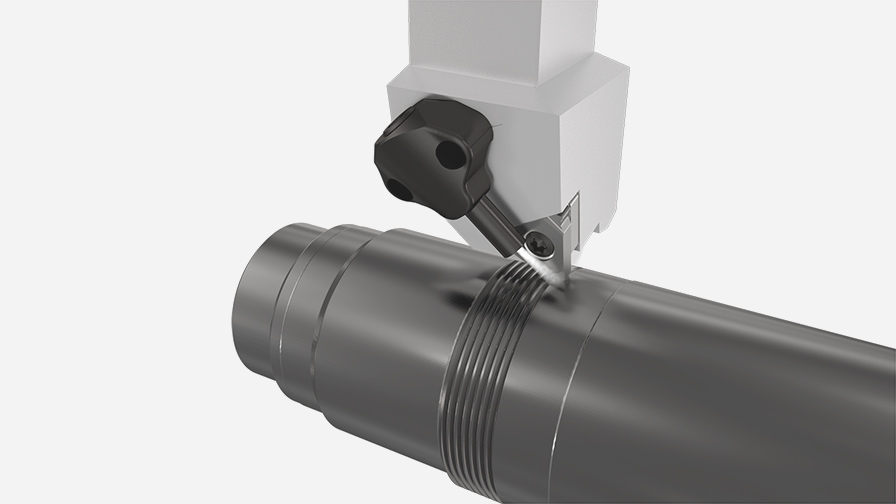

Process 2: External threading

Benefits

- TungTurn-Jet holder improves chip control by suppling coolant directly to the cutting edge, even in thread turning, which is difficult to control chips

- Prevents insert wear by enhancing the cooling effect on the cutting edge with TungTurn-Jet, and helps to maintain thread shape during machining

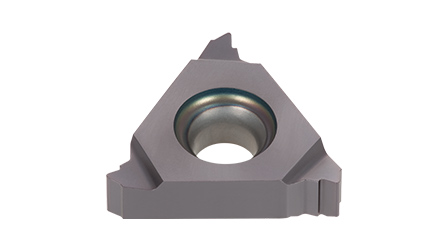

- High precision ground inserts for secure thread accuracy

- M class threading insert with chip breaker improves chip control and cost efficiency

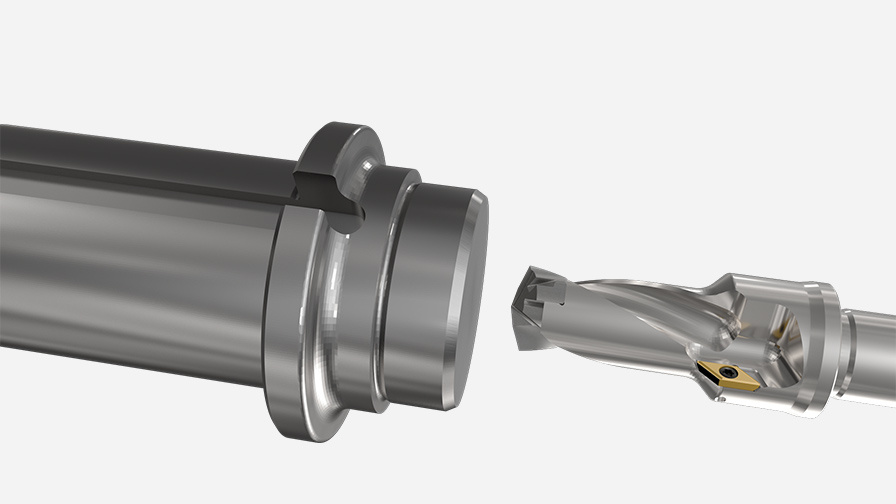

DMP drill head

- Smooth radius edge honing provides low cutting force

- Latest AH9130 grade ensures long tool life in low carbon steel

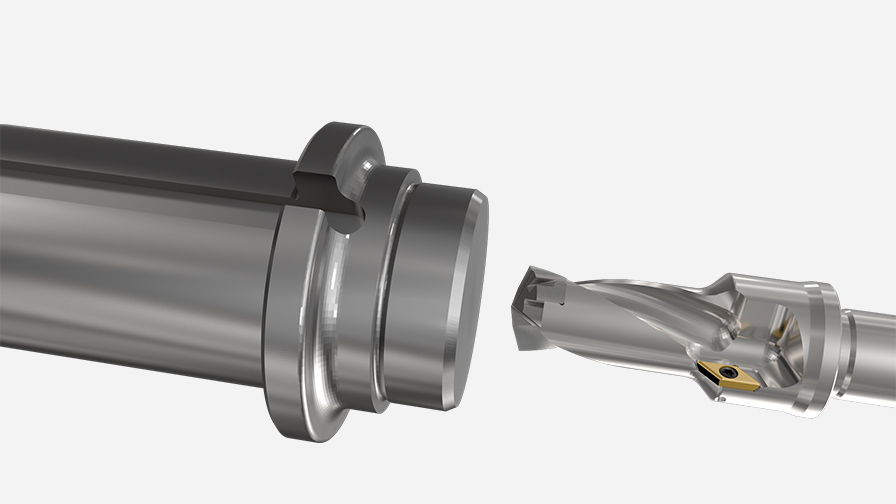

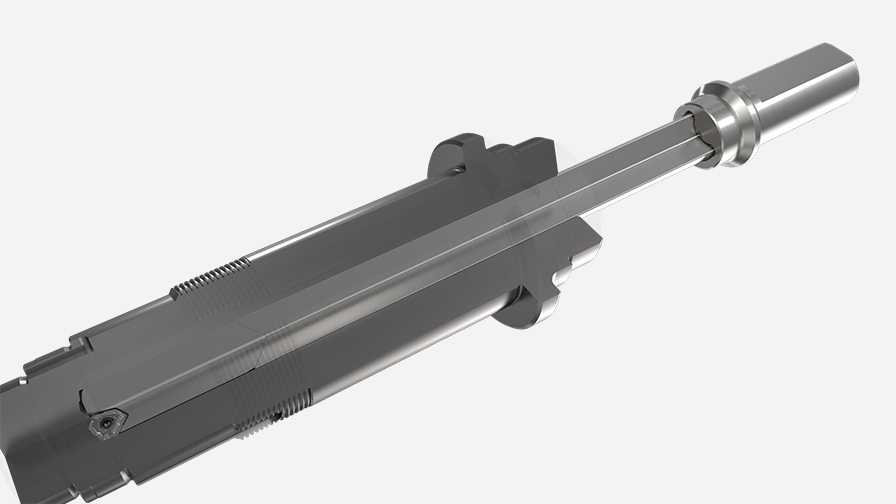

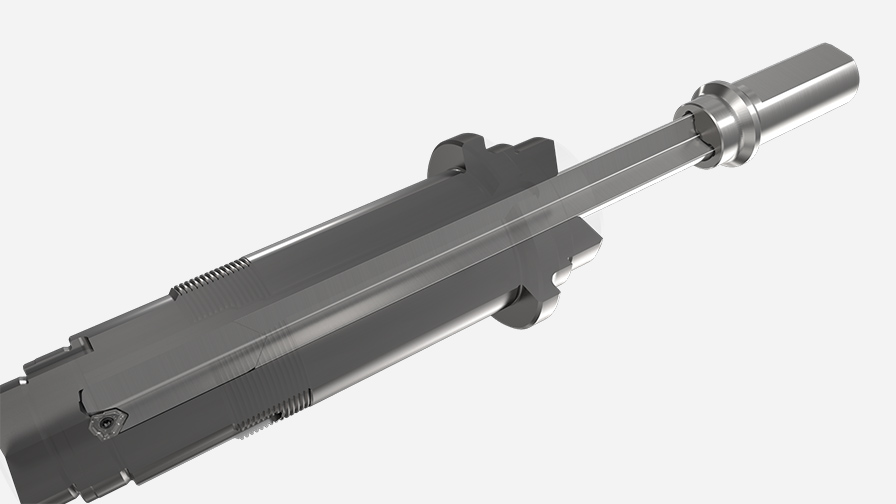

Process 4: Deep drilling

Benefits

- Apply gun drilling method in order to achieve the high dynamic balance requirement of the shaft. Gun drilling is a drilling method to get the highest straightness

- DeepTri-Drill indexable insert gun drill provides remarkably higher productivity than conventional brazed gun drills. In addition, it eliminates re-grinding operations and provides easy tool management

- Chip splitter on the insert splits the chips into small segments and creates small chips. Small chips are easily evacuated from the hole even with common coolant pressure on normal milling machines and lathes

- Chip splitter on the insert creates small chips to evacuate them easily

- High rake angle insert reduces the cutting force and allows high feed rate

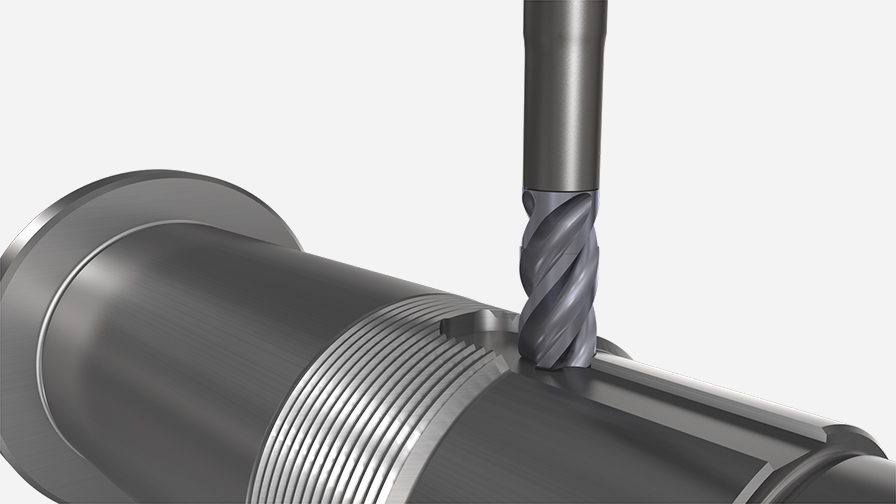

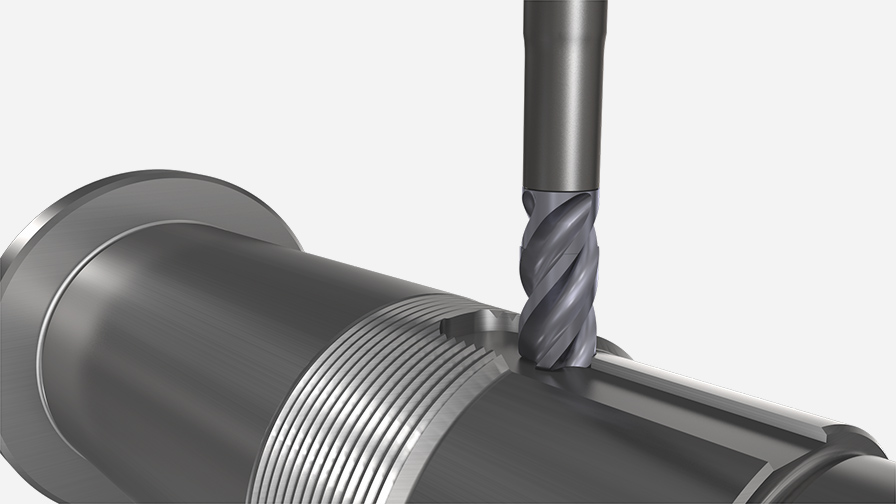

VEH head

- Variable helix, Variable pitch prevents chattering

- Latest AH715 grade extend tool life in low carbon steel

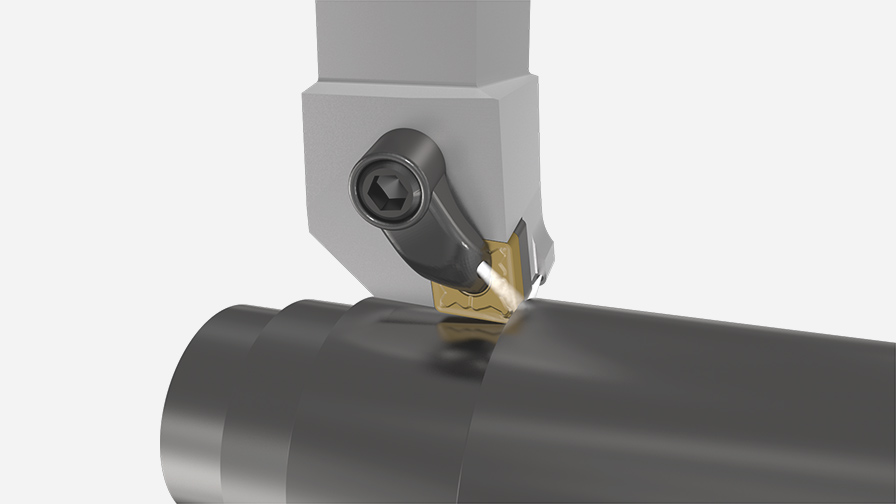

Process 6: Hard turning

Benefits

- WavyJoint insert with has large brazing area effectively dissipates the heat generated at the cutting edge during machining. It reduces cutting edge temperature and helps to reduce crater wear

- The cutting edge temperature is further reduced with the cooling effect of the TungTurn-Jet holder. The combination of the insert and the holder greatly improves tool life

- WavyJoint insert with large brazing area has strong brazing stiffness and provides high reliability even in interrupted machining area

![]()

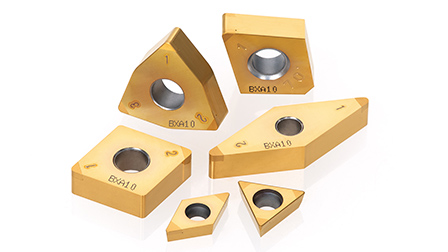

- Incredible reliability in hardened steel turning

- First choice for continuous to light interrupted cuts in hardened steel turning

![]()

- CBN insert with new brazing technology for high efficiency hardened steel machining

- Robust as ever! For outstanding performance in hard turning applications