High speed face milling cutter for finishing aluminum

Super high density PCD cutter with innovative insert clamp design for quick and easy insert setting

Applications & Features

Applications

Features

Super high density cutter for efficient finishing of aluminum

• Extremely high number of PCD cutting edges.

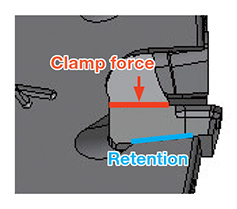

• Safety insert lock against centrifugal force for high speed milling.

CamAdjust system

• innovative insert axial adjusting mechanism.

Inserts & Grades

Inserts

YDEN0603PDF/SR-D

- Maximum depth of cut: 4.5 mm

- Standard insert with built-in deburrer

YDEN0603PDFR-BD/WD

- BD: Deburring insert, WD: Wiper insert for surface finishing

- Use with standard inserts

YDEN0603PDCR-LD

-

Long edged insert

- Maximum depth of cut: 9.5mm

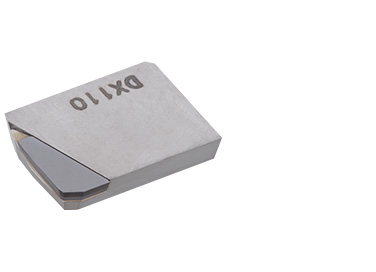

Grades

DX110

![]()

- Excellent sharpness for high surface quality

- Suitable for finishing non-ferrous metal and nonmetal

Cutter bodies

Practical examples

Example #1

Automotive Industry

| Part: | Hoist body part |

| Material: | High pressure aluminum die cast (ADC12) |

| Cutter: | TPYD06J080B25.4R16 (ø80 mm, z = 16) |

| Insert: | YDEN0603PDFR-D |

| Grade: | DX110 |

| Cutting conditions: | Vc = 2011 (m/min) fz = 0.1 (mm/t) Vf = 12800 (mm/min) ap = 4/1 (mm) ae = 5 – 20 (mm) Application: Face milling Coolant: Wet (External) Machine: Vertical M/C, BT50 |

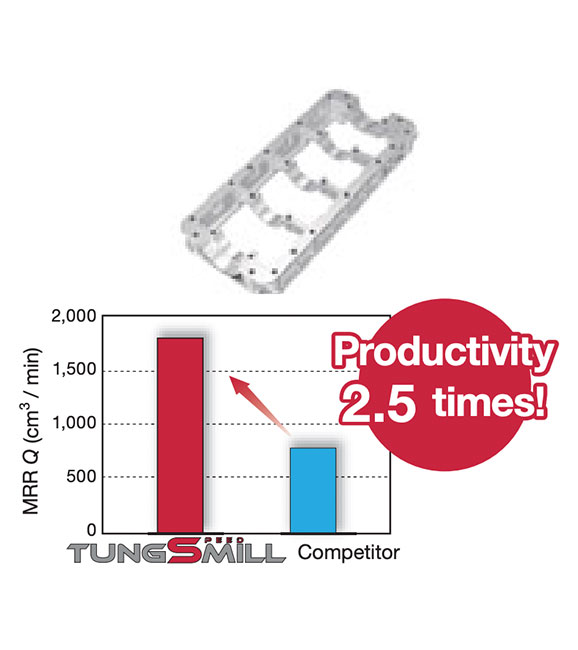

Example #2

Automotive Industry

| Part: | Crank casing |

| Material: | High pressure aluminum die cast (ADC12) |

| Cutter: | TPYD06J100B31.7R22 (ø100 mm, z = 22) |

| Insert: | YDEN0603PDFR-D |

| Grade: | DX110 |

| Cutting conditions: | Vc = 3142 (m/min) fz = 0.09 (mm/t) Vf = 20,000 (mm/min) ap = 4.5/1.5 (mm) ae = 10 – 70 (mm) Application: Face milling Coolant: Wet (Internal) Machine: Vertical M/C, BT40 |

Example #3

Automotive Industry

| Part: | Cam housing |

| Material: | High pressure aluminum die cast (ADC12) |

| Cutter: | Special TPYD06 body (ø61 mm, z = 10) |

| Insert: | YDEN0603PDSR-D |

| Grade: | DX110 |

| Cutting conditions: | Vc = 1916 (m/min) fz = 0.11 (mm/t) Vf = 11400 (m/min) ap = 0.5 (mm) ae = – 5 (mm) Application: Face milling Coolant: Wet (Internal) Machine: Vertical M/C, BT30 |

Standard cutting conditions

| ISO | Workpiece materials | Grades | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|

| Cast aluminum alloy / Die-cast (Si < 13%) |

DX110 | 500 – 4,000 | 0.05 – 0.2 | |

| Cast aluminum alloy / Die-cast (Si ≥ 13%) |

DX110 | 200 – 800 | 0.05 – 0.2 | |

| Aluminum alloy (1000 – 7000 series) |

DX110 | 500 – 4,000 | 0.05 – 0.2 | |

| Copper alloy | DX110 | 200 – 500 | 0.05 – 0.2 |

- The values in the above list are of standard recommendations and may require adjustments in consideration with cutting depths and/or workpiece/machine rigidity.

- Use wiper inserts (-WD) for better surface requirements and deburring inserts (-BD) to remove burrs.

- Always use wet cutting (emulsion coolant) for machining aluminum or copper alloys.

For more information about this product, visit our online e-catalog or download the product report: