Shoulder milling cutter with strong and smooth cutting edges

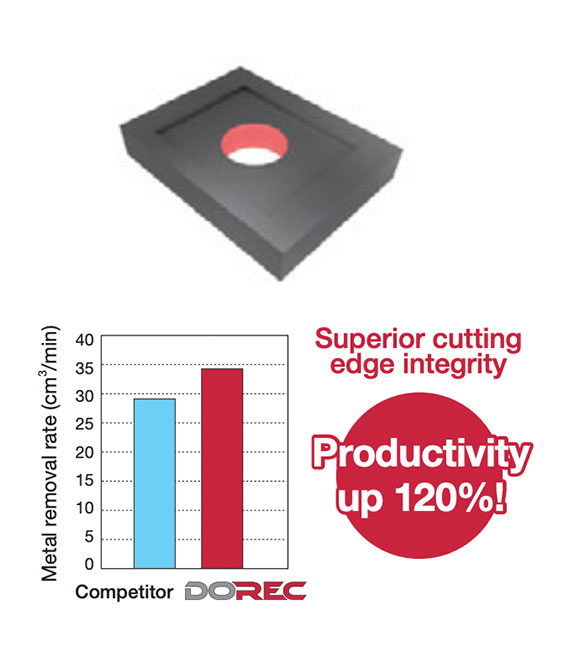

Optimized cutting edge integrity for maximum productivity and tool reliability

Applications & Features

Applications

Features

1. Broad range of economical double-sided inserts with 4 edges

2. 2 types inserts are available

• LQMU11-E-MJ for 3D machining

• LQMU11/18-MJ for general shoulder milling

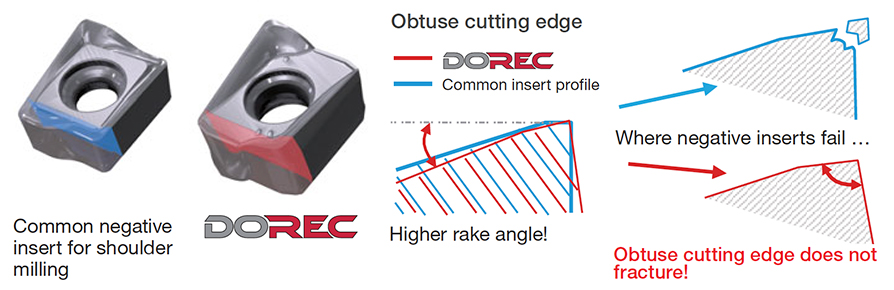

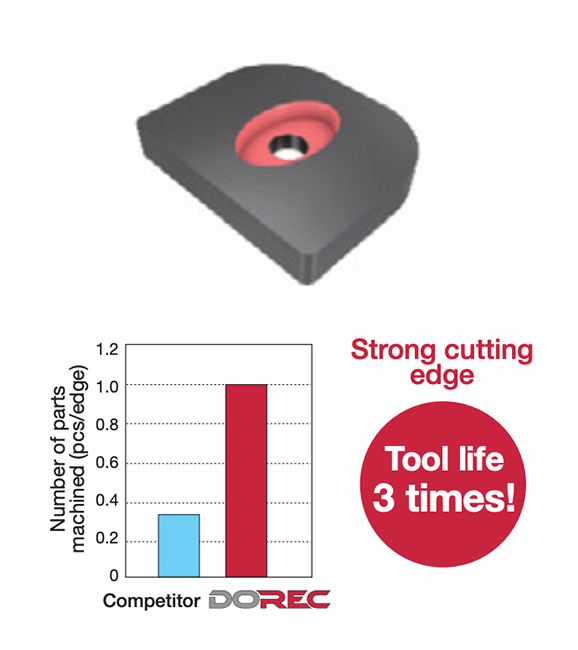

3. Superior cutting edge integrity

4. Higher feed-per-tooth capability

Inserts & Grades

Inserts

LQMU11-X

- Maximum depth of cut = 9 mm

- Unique clearance design enables 3D milling

LQMU11/18-MJ

- Maximum depth of cut

– LQMU11-MJ: 9 mm

– LQMU18-MJ: 16 mm - Universal geometry for superior surface finish

LQMU11/18-ML

- Maximum depth of cut

– LQMU11-ML: 9 mm

– LQMU18-ML: 16 mm - Light cutting geometry

Main Grades

AH3225

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for steel and stainless steel

AH3135

![]()

![]()

- High fracture resistance

- Suitable for machining steel and stainless steel under general cutting conditions

AH8015

![]()

![]()

![]()

![]()

![]()

-

Good balance between wear and fracture resistance

-

First choice for machining heat-resistant alloy under general cutting conditions

T1215

![]()

- Good balance between wear and chipping resistance

- Suitable for milling cast iron

AH120

![]()

![]()

![]()

![]()

- Good balance between wear and fracture resistance

- Suitable for machining steel, stainless steel, and cast iron under general cutting conditions

AH140

![]()

- High fracture resistance

- Suitable for milling stainless steel

AH725

![]()

![]()

![]()

![]()

- Good balance between wear and chipping resistance

- Suitable for machining steel and stainless steel under general cutting conditions

Cutter bodies

Practical examples

Example #1

General Engineering

| Part: | Flange sheet |

| Material: | Martensitic stainless steel |

| Cutter: | TPQ11R080M27.0E10 (ø80, z = 10) |

| Insert: | LQMU110708PXER-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 180 (m/min) fz = 0.15 (mm/t) Vf = 1074 (mm/min) ap = 1.0 (at 1.0 mm helix pitch) (mm) ae = 50 (mm) Application: Hole enlargement by helical interpolation Coolant: Dry Machine: Vertical M/C, BT50 |

Example #2

General Engineering

| Part: | Machine parts |

| Material: | S55C / C55 |

| Cutter: | TPQ11R050M22.0E06 (ø50, z = 6) |

| Insert: | LQMU110708PXER-MJ |

| Grade: | AH3135 |

| Cutting conditions: | Vc = 180 (m/min) fz = 0.15 (mm/t) Vf = 1035 (mm/min) ap = 9 (competitor’s ap = 8) (mm) ae = 26 (mm) Application: Shoulder milling Coolant: External supply Machine: Vertical M/C, BT50 |

Example #3

General Engineering

| Part: | Base plate |

| Material: | SS400 / E275A |

| Cutter: | TPQ11R040M16.0E04 (ø40, z = 4) |

| Insert: | LQMU110708PXER-MJ |

| Grade: | AH120 |

| Cutting conditions: | Vc = 176 (m/min) fz = 0.15(Competitor: fz = 0.12) (mm/t) Vf = 860(Competitor: Vf = 720) (mm/min) ap = 4 (0.38ºramp approach) (mm) ae = 10 (mm) Application: Hole enlargement, helical interpolation Coolant: External supply Machine: Vertical M/C, BT50 |

Standard cutting conditions

| ISO | Workpiece material | Hardness | Priority | Chipbreaker | Grade | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|---|

|

Low carbon steel S15C, etc. C15E4, etc. |

– 200 HB | First Choice | MJ | AH3225 | 100 – 250 | 0.1 – 0.25 | |

| Low cutting force | ML | AH3225 | 100 – 250 | 0.1 – 0.25 | ||||

| High carbon steel S45C, S55C, etc. C45, C55, etc. |

200 – 300 HB | First Choice | MJ | AH3225 | 100 – 230 | 0.1 – 0.2 | ||

| Low cutting force | ML | AH3225 | 100 – 230 | 0.1 – 0.2 | ||||

| Alloy steel SCM440, SCr415, etc. 42CrMo4, etc. |

– 300 HB | First Choice | MJ | AH3225 | 100 – 230 | 0.1 – 0.2 | ||

| Low cutting force | ML | AH3225 | 100 – 230 | 0.1 – 0.2 | ||||

| Tool steel SKD11, etc. X153CrMoV12, etc. |

30 – 40 HRC | First Choice | MJ | AH3225 | 100 – 180 | 0.1 – 0.2 | ||

| Low cutting force | ML | AH3225 | 100 – 180 | 0.1 – 0.2 | ||||

|

Stainless steel SUS304, etc. X5CrNi18-9, etc. |

– 200 HB | First choice | ML | AH3135 | 90 – 180 | 0.1 – 0.25 | |

| Fracture resistance | MJ | AH3135 | 90 – 180 | 0.1 – 0.25 | ||||

|

Grey cast iron FC250, etc. 250, etc. |

150 – 250 HB | First choice | MJ | AH8015 | 140 – 250 | 0.1 – 0.25 | |

| Low cutting force | ML | AH8015 | 140 – 250 | 0.1 – 0.25 | ||||

| Wear resistance | MJ | T1215 | 200 – 400 | 0.1 – 0.25 | ||||

| Ductile cast iron FCD400, etc. 450-10S, etc. |

150 – 250 HB | First choice | MJ | AH8015 | 110 – 200 | 0.1 – 0.25 | ||

| Low cutting force | ML | AH8015 | 110 – 200 | 0.1 – 0.25 | ||||

| Wear resistance | MJ | T1215 | 150 – 300 | 0.1 – 0.25 | ||||

|

Titanium alloy Ti-6Al-4V, etc. |

– | First choice | ML | AH3135 | 30 – 60 | 0.08 – 0.2 | |

| Fracture resistance | MJ | AH3135 | 30 – 60 | 0.08 – 0.2 | ||||

| Superalloys Inconel 718, etc. |

– | First choice | ML | AH8015 | 20 – 50 | 0.06 – 0.15 | ||

| Fracture resistance | MJ | AH8015 | 20 – 50 | 0.06 – 0.15 | ||||

|

Hardened steel | SKD61, etc. X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | MJ | AH8015 | 45 – 70 | 0.08 – 0.15 |

| SKD11, etc. X153CrMoV12, etc. |

50 – 60 HRC | First choice | MJ | AH8015 | 40 – 65 | 0.06 – 0.1 | ||

For more information about this product, visit our online e-catalog or download the product report: