TungThread Expansion of AH8015 grade threading inserts with chipbreaker!

Iwaki, Japan – September, 2024 – Tungaloy Corporation (President: Satoshi Kinoshita, Head Office: Iwaki City, Fukushima Prefecture) announces the expansion of its TungThread series, now featuring new thread turning inserts with a 3D chipbreaker and the latest AH8015 grade. The AH8015 grade delivers superior wear and chipping resistance, enabling high precision in a variety of threading applications, including ISO metric, UN, and NPT threads, while ensuring enhanced chip control and extended tool life.

Challenges and Trends

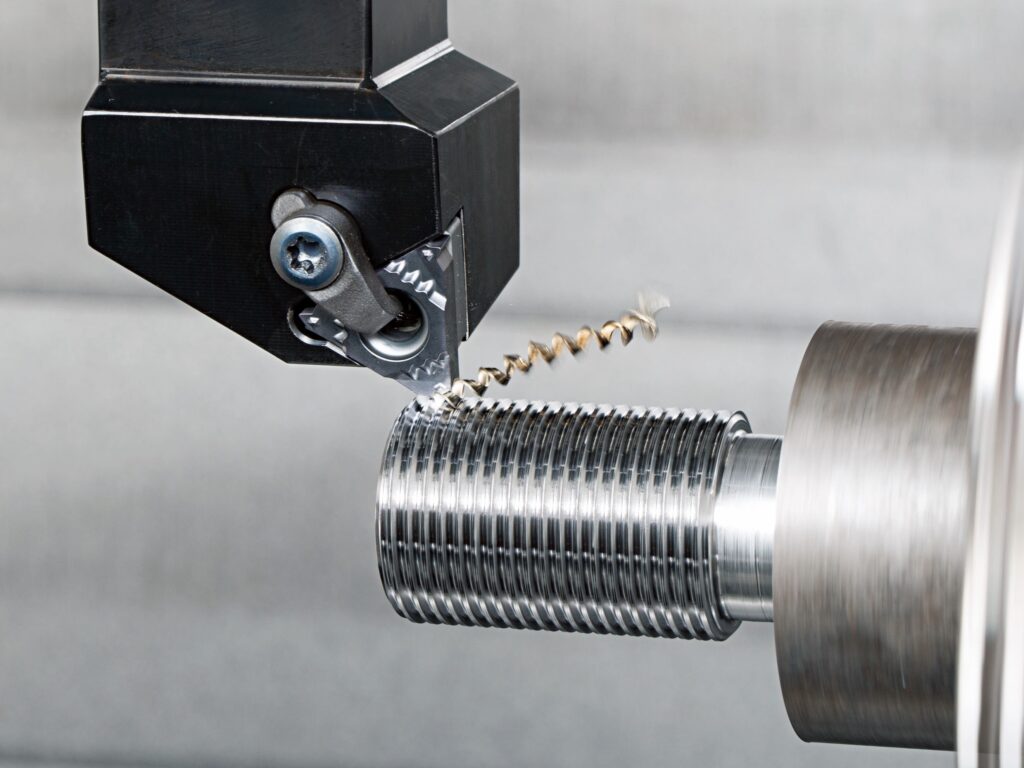

Thread turning is an essential process in a wide range of industries, including automotive, aerospace, and industrial machinery. However, one of the major challenges faced in this process is chip control.

Chips can become entangled with the workpiece, leading to insert breakage or scratching of the workpiece surface, which frequently occurs. Additionally, in thread turning, unlike other cutting processes, it is difficult to make significant changes to the cutting parameters, making it challenging to improve chip control solely by adjusting the machining conditions.

As a result, many users have no choice but to rely on the performance of the cutting tools themselves. Furthermore, thread turning requires high dimensional accuracy, making it essential to extend the life of the insert while maintaining both sharpness and wear resistance. At the same time, the tool must have sufficient toughness to withstand the impact during cutting, which necessitates high chipping resistance. Users are seeking solutions that can address these complex machining demands.

Product Overview

TungThread series is a high-performance threading tool offered by Tungaloy. It is compatible with a wide range of machines such as NC lathes, automatic lathes, and large lathes, and it demonstrates exceptional performance particularly in threading for API-standard oil pipes.

The series accommodates a variety of thread shapes, providing a reliable solution that meets the diverse needs of manufacturers.

Benefits and Features

Feature 1: Improved Chip Control with 3D Chipbreaker

– The optimized positioning of the chip breaker protrusions significantly enhances chip control.

– Even in challenging situations like radial infeed, stable curled chips can be obtained, ensuring smooth chip evacuation.

– This reduces chip entanglement and surface finish issues, leading to improved productivity and extended tool life.

Feature 2: High Wear and Chipping Resistance with AH8015 Grade

– The latest AH8015 grade features an Al-rich coating, improving coating hardness by 20% compared to conventional products, ensuring long tool life even under severe cutting conditions.

– Layering technology in the coating suppresses the progression of microcracks, enhancing chipping resistance.

– The enhanced adhesion strength of the coating effectively prevents boundary damage, which is especially common in machining heat-resistant alloys.

– Capable of handling various thread types such as ISO metric threads, Unified threads, and NPT threads, it offers high versatility across a wide range of work materials.

Cutting Performance

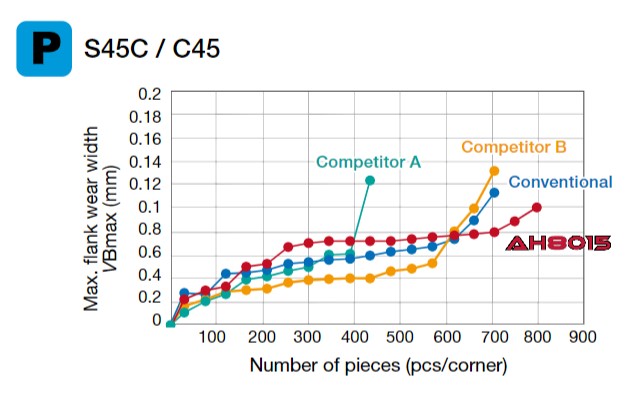

Tool Life Comparison

| Insert | 16ER15IS |

| Cutting speed | Vc = 80 m/min |

| Pitch | p = 1.5 mm |

| Machining | External threading |

| Infeed method | Radial infeed |

| Coolant | Wet |

AH8015 provided good wear resistance for threading stainless steel parts.

| Insert | 16ER15IS |

| Cutting speed | Vc = 150 m/min |

| Pitch | p = 1.5 mm |

| Machining | External threading |

| Infeed method | Radial infeed |

| Coolant | Wet |

AH8015 provided good wear resistance for threading steel parts.

Success Stories

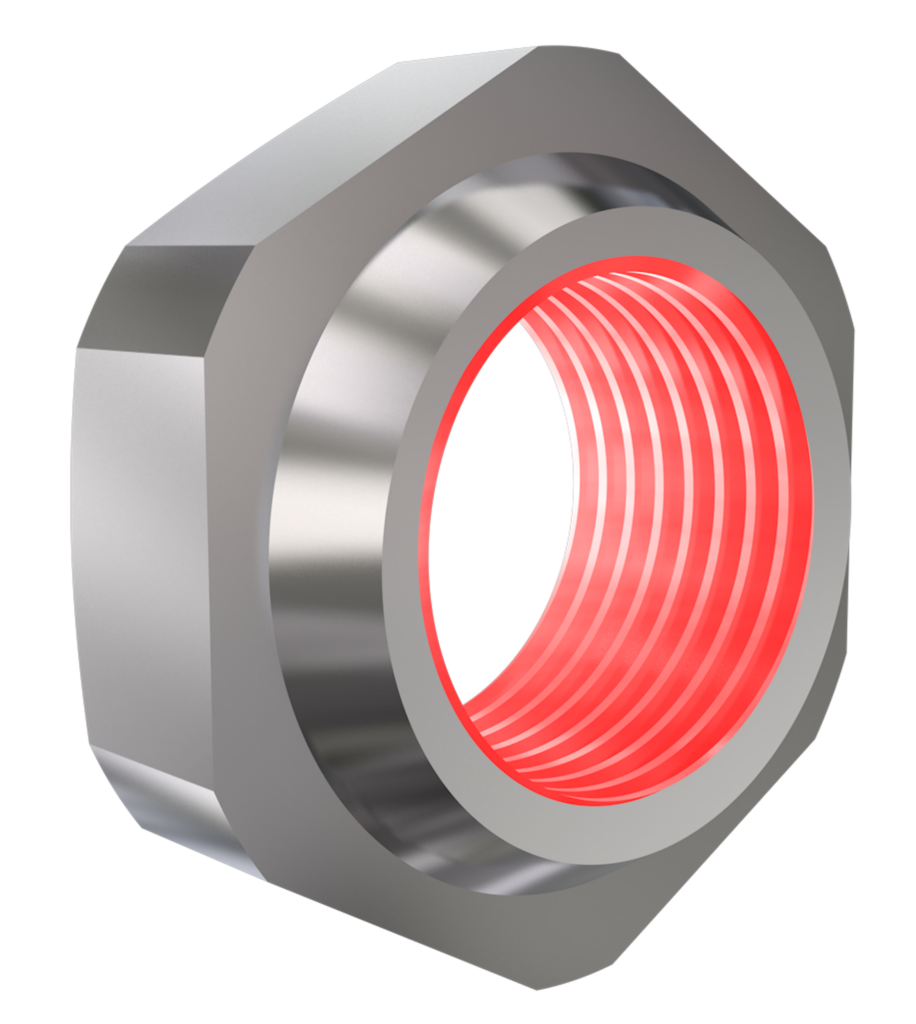

IMPROVED TOOL LIFE

With the wear- and chipping-resistant AH8015 grade, the TungThread threading insert provides double the tool life. The pressed 3D chipbreaker helps improve chip control and productivity.

| Industry | Engineering |

| Component | Union nut |

| Material ISO code | |

| Work material | SUS304/X5CrNi18-10 |

| Machine(Spindletype) | CNC Lathe |

| Tool family | Turning |

| Toolcategory | Internal threading |

| Product name | TungThread |

| TSR No. | 5060T |

IMPROVED TOOL LIFE AND PRODUCTIVITY

With the wear-resistant AH8015 grade, combined with a 3D chipbreaker for better chip control, the TungThread threading insert provided a 1.7-times increase in productivity and a 1.3-times increase in tool life.

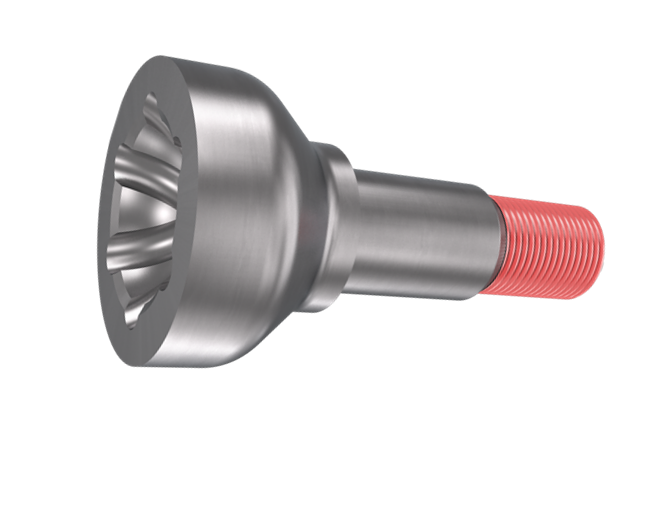

| Industry | Automotive |

| Component | CVJ outer race |

| Material ISO code | |

| Work material | S53C |

| Machine(Spindletype) | CNC Lathe |

| Tool family | Turning |

| Toolcategory | External threading |

| Product name | TungThread |

| TSR No. | 5061T |