Multifunctional counterboring tool with enriched tool diameter line up

Enriched tool diameter lineup for various hole making operations

Applications & Features

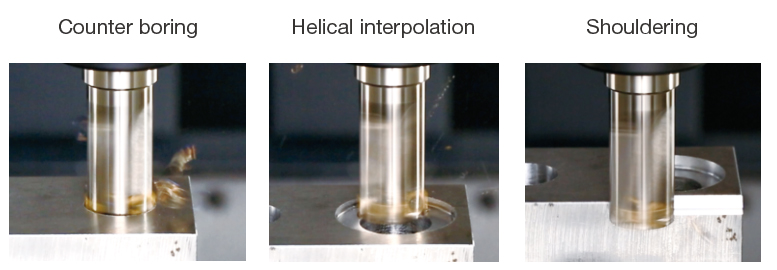

Applications

Features

1. Wide variety of tools for various counterboring operations

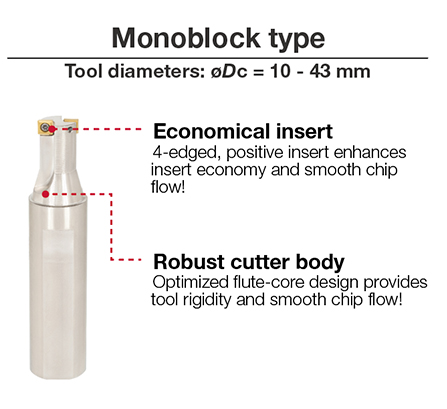

2. 2 types of endmills available

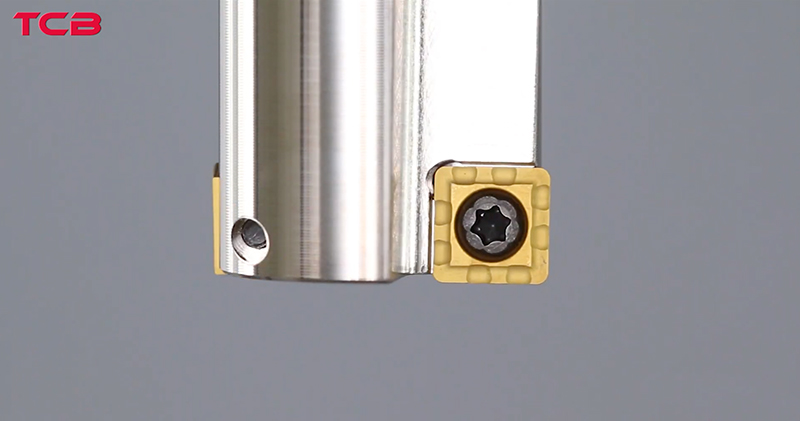

• Mono-block type: ø10 – ø43mm

• Cartridge type: ø26 – ø59mm, Diameter adjustable with shims

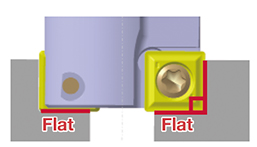

3. Provides a 90° flat surface

4. Multi-functionality

Inserts & Grades

Inserts

Grades

AH6225

![]()

![]()

- P20 – P30 / M20 – M30

- First choice for stainless steel

- Excellent versatility for stainless steel machining, demonstrates a good combination of wear and fracture resistance

T313W

![]()

![]()

![]()

![]()

![]()

Cutter bodies

Practical examples

Example #1

Automotive Industry

| Part: | Con-rods |

| Material: | S55C / C55 |

| Drill: | TCB170F25 |

| Insert: | SPMP831DS |

| Grade: | T313W |

| Cutting conditions: | Vc = 160 (m/min) f = 0.2 (mm/rev) Vf = 600 (mm/min) H = 24 (mm) Application: Boring Coolant: Wet Machine: Dedicated machine |

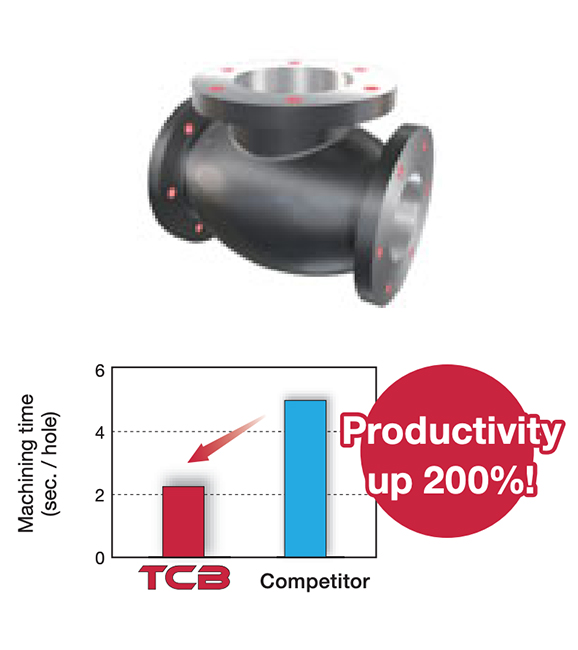

Example #2

General Engineering

| Part: | Valve |

| Material: | FC250 / GG25 / 250 |

| Drill: | TCB240F25 |

| Insert: | SPMP042ERD |

| Grade: | T313W |

| Cutting conditions: | Vc= 180 (m/min) f= 0.3 (mm/rev) Vf= 720 (mm/min) H= 30 (mm) Application: Boring Coolant: Wet Machine: Horizontal M/C, BT50 |

Example #3

General Engineering

| Part: | Bearing |

| Material: | S45C / C45 |

| Drill: | TCB-320 |

| Insert: | SPMM322ERD |

| Grade: | T313W |

| Cutting conditions: | Vc= 150 (m/min) f= 0.25 (mm/rev) Vf= 375 (mm/min) H= 40 (mm) Application: Boring Coolant: Wet Machine: NC lathe |

Standard cutting conditions

Counter boring

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Feed : f (mm/rev) | |

|---|---|---|---|---|---|

| ø10 – 12 (z = 1) | ø13 – 59 (z = 2) | ||||

|

Carbon steel | – 300 HB | 80 – 200 | 0.03 – 0.08 | 0.1 – 0.3 |

|

Stainless steel | – 200 HB | 80 – 150 | 0.03 – 0.05 | 0.06 – 0.15 |

|

Grey cast iron | 150 – 250 HB | 80 – 200 | 0.05 – 0.1 | 0.1 – 0.4 |

|

Non-ferrous | – | 100 – 300 | 0.05 – 0.2 | 0.1 – 0.4 |

|

Superalloys | – 40 HRC | 50 – 80 | 0.03 – 0.05 | 0.06 – 0.15 |

|

Hard materials | – 50 HRC | 50 – 80 | 0.03 – 0.05 | 0.06 – 0.15 |

Milling

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|

|

Carbon steel | – 300 HB | 80 – 200 | 0.05 – 0.15 |

|

Stainless steel | – 200 HB | 80 – 150 | 0.05 – 0.1 |

|

Grey cast iron | 150 – 250 HB | 80 – 200 | 0.05 – 0.2 |

|

Non-ferrous | – | 100 – 300 | 0.1 – 0.2 |

|

Superalloys | – 40 HRC | 50 – 80 | 0.05 – 0.08 |

|

Hard materials | – 50 HRC | 50 – 80 | 0.05 – 0.08 |

Internal boring (With one cutting edge)

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Depth of cut ap (mm) |

Feed fz (mm/t) |

|---|---|---|---|---|---|

|

Carbon steel | – 300 HB | 80 – 200 | 0.5 – | 0.05 – 0.15 |

|

Stainless steel | – 200 HB | 80 – 150 | 0.5 – | 0.05 – 0.1 |

|

Grey cast iron | 150 – 250 HB | 80 – 200 | 0.5 – | 0.05 – 0.2 |

|

Non-ferrous | – | 100 – 300 | 0.5 – | 0.1 – 0.2 |

|

Superalloys | – 40 HRC | 50 – 80 | 0.5 – | 0.05 – 0.08 |

|

Hard materials | – 50 HRC | 50 – 80 | 0.5 – | 0.05 – 0.08 |

For more information about this product, visit our online e-catalog or download the product report: