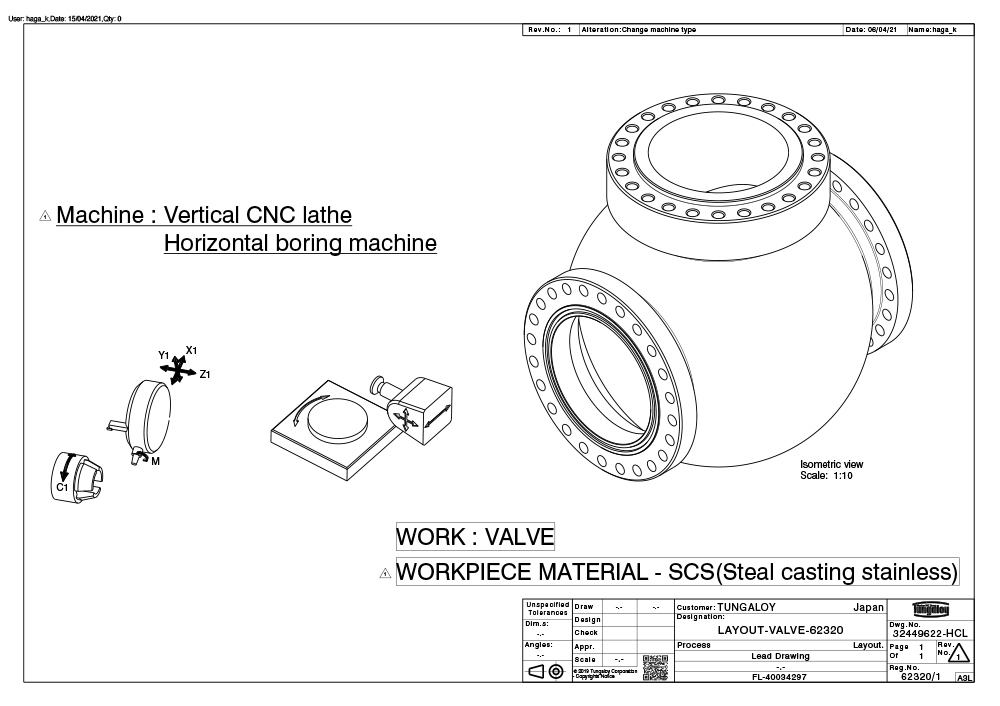

Oil & Gas – Valves

Industrial valves are used in many process industries to control fluids such as slurries, gases, and steam flowing piping systems.

Ball valves for the petroleum industry are used under severe operating conditions that require high corrosion resistance, heat resistance, pressure resistance, and oxidation resistance, so products are required to have higher durability and reliability. In order to meet these high-quality requirements, it is important to select tools that achieve stable and high accuracy machining.

Tungaloy offers advanced cutting tools and effective solutions to improve productivity that leads to stable machining and improved profitability for Industrial valves machining.

Tooling concepts

- Selection of tools that ensure stable tool life even when machining forged surfaces where insets are likely to chip

- Use of a boring tool that allows easy fine adjustment of the tool diameter even on the machine

- Applied thread cutting by thread mill. Achieves stable threading to prevent unexpected issues such as sudden tool breakage

- Highly efficient slotting that achieves stable chip creation and evacuation

- Tool selection that achieves high accuracy and reliability in large-diameter hole drilling

- Use of head exchangeable tools to reduce tool setup time, and tool management

Featured process

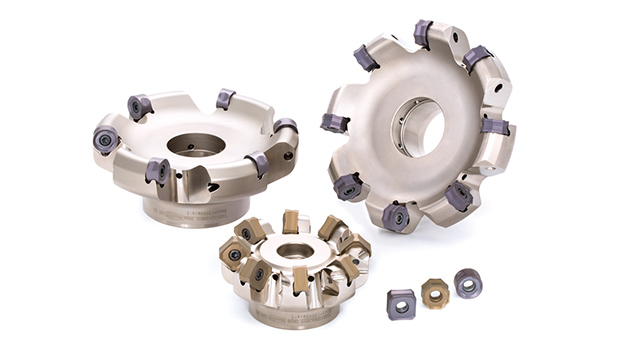

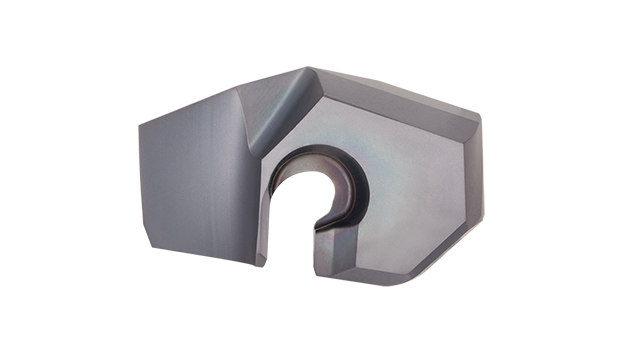

Process 1: Rough face milling

Benefits

- The dovetail insert clamping structure that strongly clamps the inserts achieves long tool life and stable machining even during heavy machining. Demonstrates high reliability in processing on forged surfaces where inserts are likely chip.

- The concave shape of the cutting edge produces barrel-shaped chips, enabling good chip control even for work materials such as stainless cast steel where chips tend to be long.

- Large rake angle reduces cutting force.

- The octagonal double-sided ONGU insert is highly economical with 16 cutting edges.

![]()

- Achieves excellent chipping resistance and fracture resistance due to the special laminated coating films.

- High-toughness substrate provides excellent thermal crack resistance.

- Prevents abnormal damage and achieves stable long tool life.

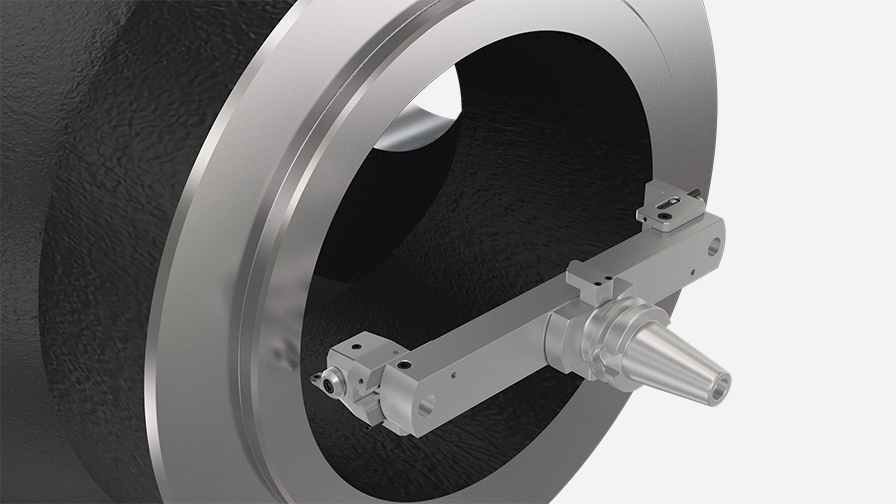

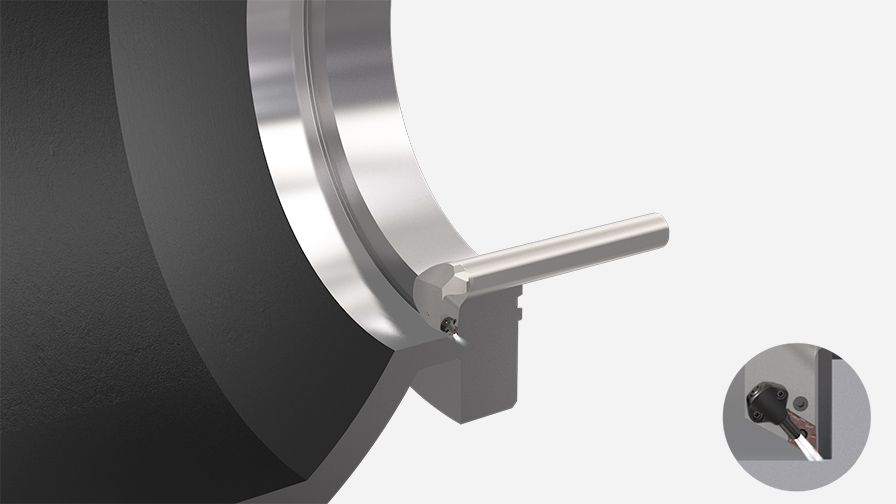

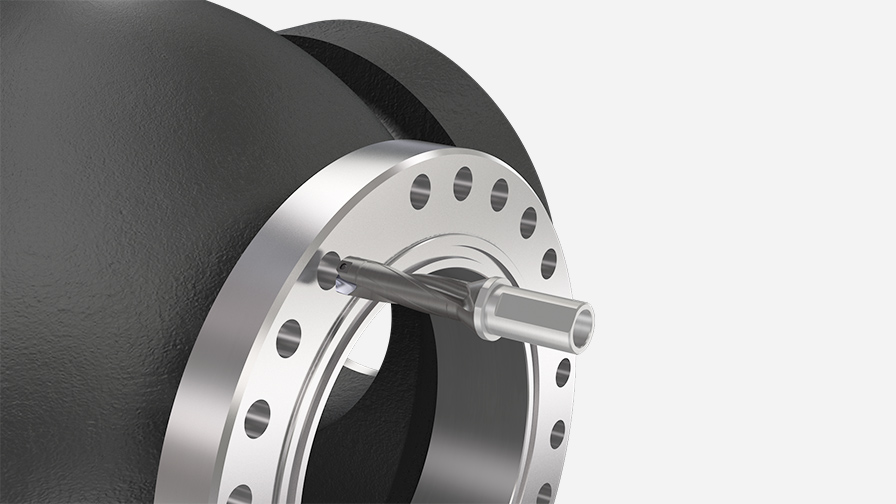

Process 2: Fine boring

Benefits

- The adoption of a digital counter enables diameter adjustment in units of 1 μm.

- The tool diameter can be checked digitally by simply inserting the digital unit into the specified location on the main body, making it easy to adjust the diameter on the machine.

- Eliminates chip control problems with internal coolant supply.

![]()

- Ideal PVD grade for finish boring with a coating film that maintains a sharp cutting edge.

- Carbide substrate with excellent balance of wear and fracture resistance.

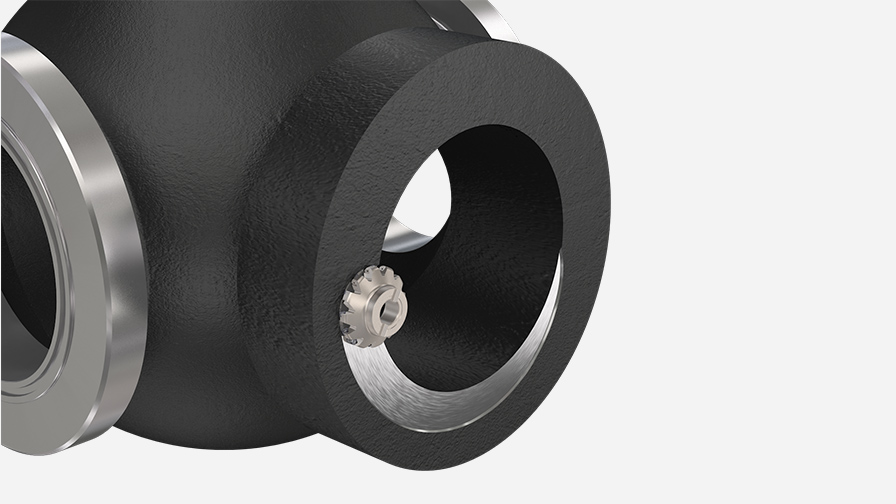

Process 3: Thread milling

Benefits

- Use thread milling for good chip control, even with stainless cast steel where chip control is difficult..

- Since the contact area of the cutting edge with the work material is smaller than that of a tap, the spindle load can be reduced. Achieves stable machining by preventing spindle stoppage due to tap breakage and torque overload.

- Achieves high productivity by using thread mill tools capable of multi-stage threading.

![]()

- Ideal for threading process with a coating film that maintains a sharp cutting edge.

- Maintains a sharp cutting edge and ensures stable screw accuracy.

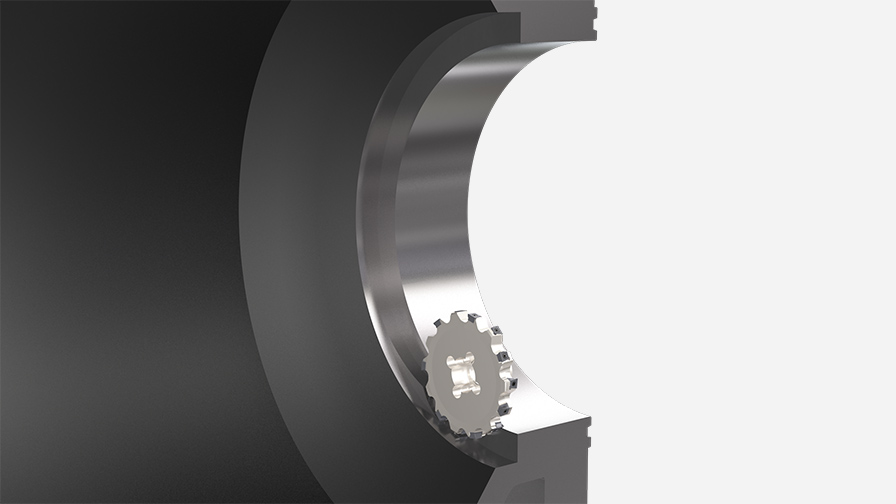

Process 4: Slotting

Benefits

- Large pocket and optimized chip breaker design provide compact chips and smooth chip evacuation. Achieves stable slotting process.

- Adoption of vertical insert with high reliability prevents sudden insert breakage and achieves stable and high-efficiency slotting.

- Inclination and large rake angle reduce cutting force.

- Double sided 4 corners insert with left and right hand provides economical solution and easy tool management.

![]()

- Achieves excellent chipping resistance and fracture resistance due to the special laminated coating films.

- High-toughness substrate provides excellent thermal crack resistance.

- Prevents abnormal damage and achieves stable long-life.

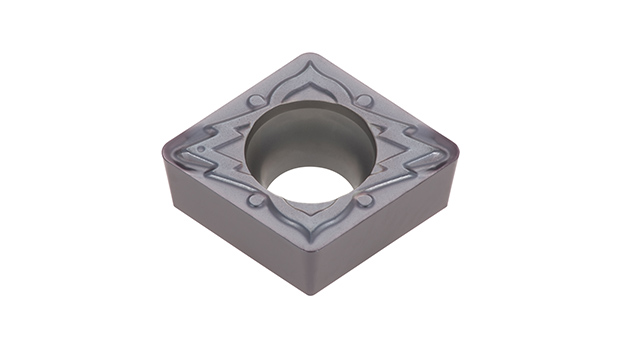

Process 5: Finish Internal turning

Benefits

- Coolant is supplied from a nozzle located near the cutting point, even when machining hard-to-reach places for coolant, and achieves stable machining by improving chip control and evacuation.

- Coolant can be supplied from both the rake face and the flank face. Accelerates the cooling effect of the cutting edge to achieve longer tool life.

![]()

- First choice grade for stainless steel in turning.

- The outer layer of the coating film uses a newly developed titanium-rich nano-layered film. Excellent wear resistance due to high hardness and dense fine-grained structure.

- Uses a dedicated substrate with excellent chipping resistance and high thermal conductivity. Quickly disperses the cutting heat generated during machining and prevents the temperature rise of the cutting edge. Significantly reduces plastic deformation.

Process 6: Drilling

Benefits

- Provides high productivity and reliability drilling by applying a 2-flute drill.

- Flute design with excellent balance between chip evacuation and rigidity.

- The wide contact surface of the drill head and body achieves high drilling accuracy and reliability in large-diameter drilling.

![]()

SMP head

- By increasing the smoothness of the coating surface, AH725 reduces adhesion to the cutting edge and improves chipping resistance.

- The adoption of R-shape edge preparation improves the adhesion of the coating film.