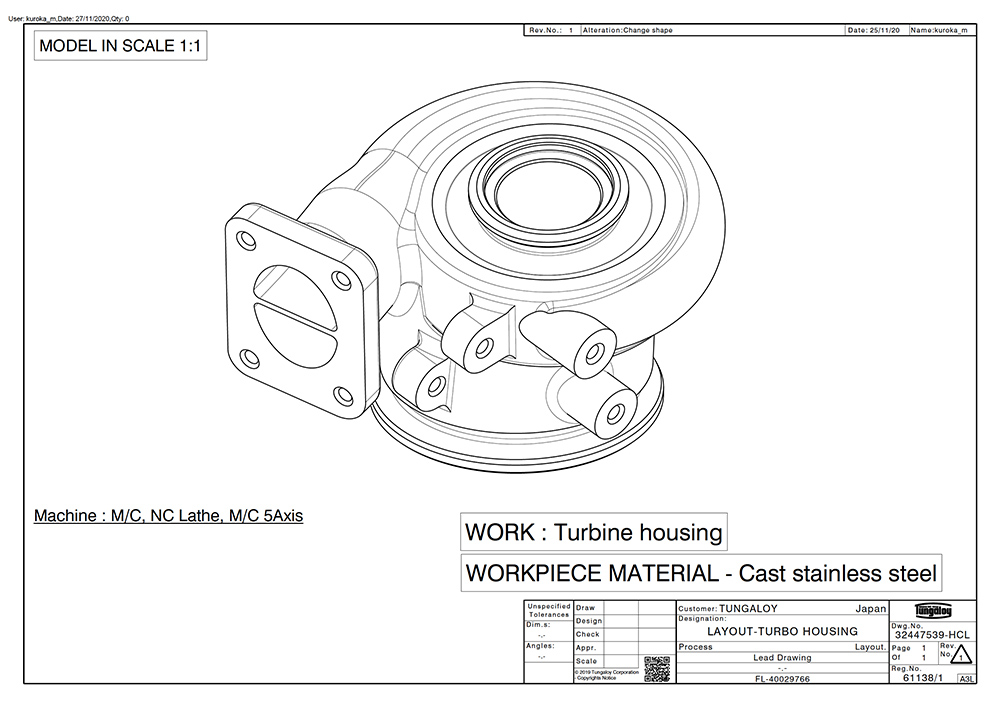

Automotive – Turbocharger Housing

Turbocharger improves an engine’s combustion efficiency to boost the power output and, due to the complex nature of the system, requires manufacturing precision. As most turbochargers are exhaust gas turbochargers, the turbine housing is manufactured from very abrasive, heat-resistant materials such as high silicon ductile iron, Ni-Resist cast iron, and heat-resistant cast steels. These materials pose a particular challenge for every machining tool.

Tungaloy’s advanced cutting tool technology provides turbocharger manufacturers with the latest solutions of cutting tool geometries and grades that maximize production efficiency in terms of improved cycle time and tool life.

General Challenges

- To improve cycle time and tool life predictability in machining abrasive difficult-to-cut materials

- To ensure stability for machining components with complex, thin-walled structure and with relatively weak fixturing

- To provide optimal solutions for every application and machine tool

- To maximize machine capacity, while minimizing downtime

Key Points

-

Low cutting forces for machining stability

- Designed with thin housing walls and complexity, turbocharger housing poses stability challenges during machining. DoForce-Tri face and shoulder mill line addresses this issue with six-edged triangular inserts with sharp cutting edges that generate light cutting action, providing stability when machining thin-walled components with poor stability. These cost-efficient inserts maintain cutting edge sharpness over an extended period of time for excellent surface finishing.

- DoQuad-Mill is designed with an optimal cutter entry angle that prevents chatter during machining and provides stability when machining walls and flanges of components. Double-sided eight-edged insert features a cutting edge with a large concavity on its rake face that helps create ideal barrel-shaped chips while cutting. The insert also has a built-in wiper for better surface results.

- TungTri is a variable pitch milling cutter for improved stability, cycle time, and cost efficiency. Its single-sided triangular inserts with three sharp cutting edges generate low cutting forces, while eliminating chatter. In combination with Tungaloy’s TungFlex modular tooling system, a greater flexibility in tooling is possible for TungTri to build an optimal assembly for a specific challenging application such as those in long-reach areas, using standard modular heads.

-

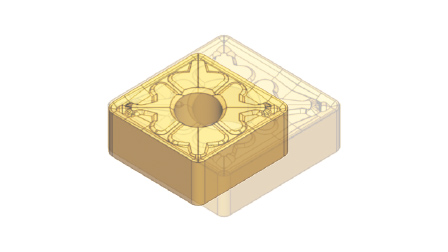

Tool reliability through long and predictable tool life

- AH8000 grade series is PVD-coated carbide grades consisting of AlTiN nano-multilayer coating with high aluminum content that are developed specifically for machining heat-resistant alloy parts: AH8015 is the first-choice grade that provides a good combination of wear resistance and fracture toughness; while AH8005 boasts superior wear resistance during machining of heat-resistant materials at elevated cutting speeds, while eliminating built-up edge.

- TungTurn-Jet through-coolant toolholder system provides precision coolant delivery to the optimal positions–close to the cutting point. This enables effective chip removal and drastically increased cutting parameters to be applied, while allowing longer tool life. The system improves insert performance and part quality, as well as prevention of built-up edge formation typical in heat-resistant part machining.

Machining Solutions

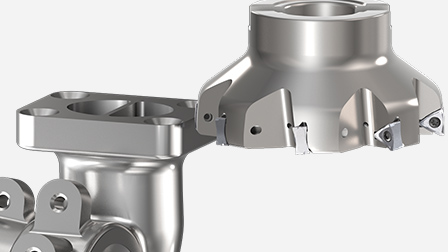

Face Milling

DoTriple-Mill

- Versatile face mill cutter with rigid insert clamping provides process security in various machining conditions from removing of abrasive scales to finish milling process

- Cost-efficient double-sided negative inserts

- Inserts are available in an array of grades and geometries for extensive application coverage

- Sets of round, square, or octagonal inserts can be fit on the single cutter body

TungForce-Rec

- Small diameter indexable end mill line featuring small inserts with strong cutting edge design

- High stability and high efficiency milling enabled by sharp cutting edges combined with close-pitch cutter configuration

- Innovative insert-pocket interface design offers rigid insert clamping for secure slot milling or pocketing process

TungQuad

- Features small-sized square inserts

- Close pitch design for high efficiency machining

- Offers shoulder and chamfer cutter bodies

Slot Milling

SlotMill series – TungUniversalSlot

- Cost-efficient side milling cutter line for high metal removal rates

- Provides superior chip evacuation and machining stability at greater slotting depths

- Economical six-edged inserts with light cutting geometry

- Cutter widths ranging from 10 mm to 16 mm

Chamfering

TungMeister

- Exchangeable head end mill series offering an extensive range of milling head profiles

- Excellent repeatability for high part precision

- No setup time – tool changes can be done without removing the shank from the spindle

TungQuad

- Features small-sized square inserts

- Close pitch design for high efficiency machining

- Offers shoulder and chamfer cutter bodies

Thread Milling

ThreadMilling

- Offers solid, exchangeable head, and indexable insert styles

- Allows full threads close to the bottom of the hole

- Broken tool can easily be changed creating zero part scraps

Hole Making

DrillMeister – specials

- Exchangeable-head drill series offering a variety of drill head profiles and shank sizes for a wide range of drilling needs

- No setup time – tool changes can be done without removing the entire tool from the machine. Hidden costs such as for tool inventory and management can significantly be reduced

- In addition to our extensive standard offer, DrillMeister also delivers customized hole making tool solutions tailored to your specific hole making needs

TungDrill-Twisted

- Large-diameter indexable drill line offering a range of insert geometries that optimize chip forms for improved process security and efficiency

- Insert grades are available for all material groups

End Milling

SolidMeister

- Solid end mill series offering a wide range of cutting edge designs in grades covering all material groups

- Sophisticated FinishMeister-VariablePitch can perform roughing and finishing operations at the same time with excellent surface finishing, while its variable-pitch variable-helix design provide process security

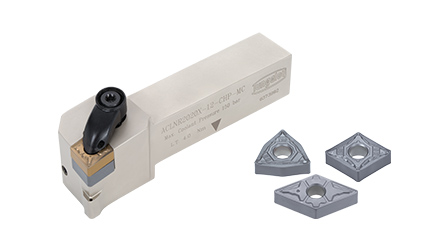

Turning

TungTurn-Jet system + AH8000s

- A combination of through-coolant turning toolholder system and dedicated insert grade for heat-resistant alloys provides process security and long tool life

- Offers highly rigid insert clamping and precision coolant delivery

- Latest PVD coating technology improves machining performance of heat-resistant alloys

ISO-EcoTurn

- Turning tool system offering downsized inserts for economy without compromising insert performance

- Helps avoid human-errors: In any process involving two almost-identical inserts, use one ISO-EcoTurn insert in place of standard ISO insert to avoid mixing up inserts and creating scrap piles

Grooving and Profiling

TungCut + TungTurn-Jet + ModularSystem

- Latest modular tooling offers highly rigid insert clamping design for extra stability and accuracy

- High-pressure through-coolant system for effective chip control and process security

- Inserts are available in a variety of geometries and grades for high efficiency machining