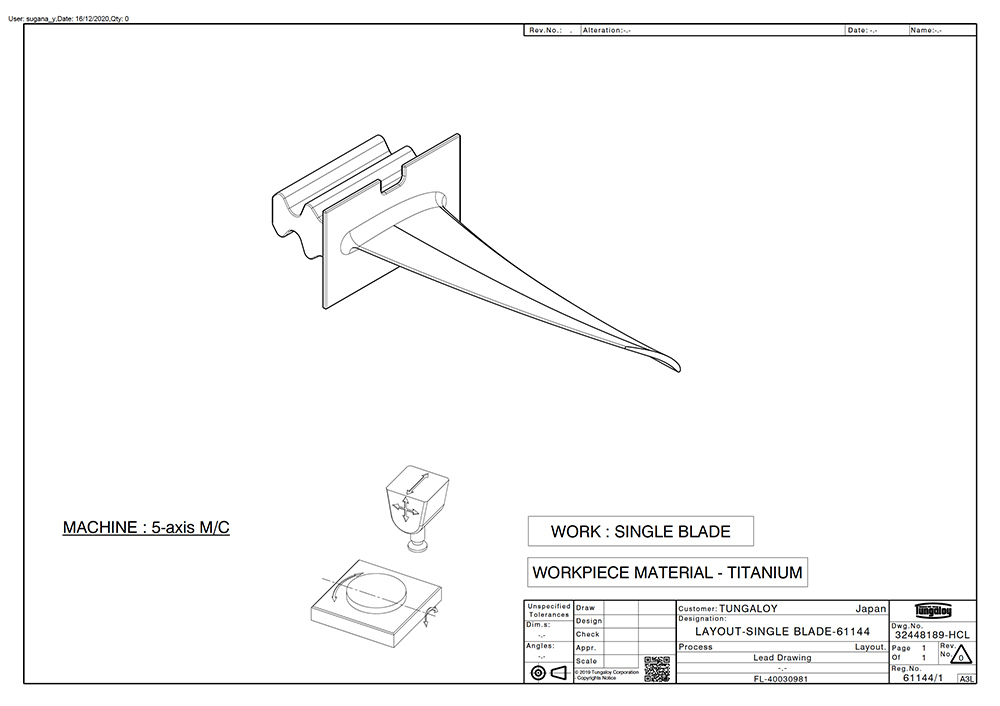

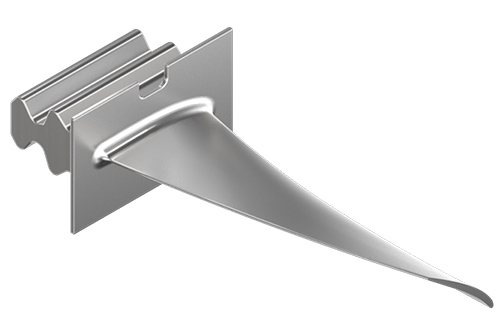

Aerospace – Turbine Blade

A jet engine turbine blade is the individual component that makes up the turbine section of an aircraft engine. The turbine blades are exposed to the harshest environment in terms of pressure and temperature, while rotating at extremely high speed. The materials of turbine blades are, therefore, difficult to machine, heat-resistant superalloys (HRSAs) with high creep strength, high temperature fatigue strength, and high temperature corrosion resistance. Nickel-based HRSAs such as Inconel and Waspaloy have high thermal properties but, in turn, substantially increases the stresses imposed on cutting tool edges during machining.

Tungaloy’s advanced lines of cutting tools offer unique machining solutions that are effective for not only HRSAs but also unique aluminum-lithium alloys and intermetallic compounds such as titanium aluminide (TiAl).

General Challenges

- To improve machining efficiency and chatter of thin-walled sections

- To reduce cutting forces when high-feed milling the blade surface in the axial direction for improved machining efficiency

- High-performing cutting tools that maximize 5-axis machines

- To maintain high part precision

Key Points

-

High surface finish milling of blade surfaces with improved cycle time on 5-axis machines

- TungMeister-Barrel head offers longer tool life, shorter cycle time, and smoother surfaces, compared with traditional ball nose mills. The cutter’s peripheral cutting edges feature a large curvature radius that facilitates a much greater engagement area between cutter and workpiece than typical ball nose counterparts. Greater engagement area, in turn, enables larger stepovers, which improve metal removal rates and surface finish with less tool wear.

Barrel milling heads are available in three profiles: VBO-short for semi-finishing of general parts, VBO-long for pre-finishing and finishing of die mold parts, and VBN for pre-finishing and finishing of turbine blade surfaces and roots, impellers, blisks, other aerospace parts

Machining Solutions

Milling

DoTwist-Ball

- Extremely productive indexable profile milling cutter with helically twisted inserts for high tool stability

- Economical insert with four cutting edges

- Offer two types of inserts that are interchangeable: round inserts or high feed inserts

- Provides excellent chip control and cost efficiency

- Available in various insert grades for wide material coverage

DoFeed

- Indexable high feed milling cutter with close-pitched insert alignment enabling efficient removal of large stock

- Reduced cycle time for roughing operation

- Double-sided insert geometry brings benefits in tool economy and productivity

- Negative inserts generate low cutting force eliminating vibration

- A wide range of tool lineup for expanded application coverage

SolidMeister-VariableMeister

- Highly productive solid carbide end mill line with sophisticated variable pitch variable helix design for anti-vibration

- Designed for large stock removal, while producing excellent surface finish and reduced machining time

TungForceFeed

- Small-diameter high feed milling cutter with high-density insert design and excellent chip evacuation

- Optimized insert geometry for higher feed rate and greater d.o.c.

- Two styles of inserts are interchangeable: radius or high feed insert

SolidMeister-FeedMeister

- Solid carbide end mill line with large radius cutting edges for greatly increased feed rates

- Suited for materials such as hardened steel up to 65 HRc, titanium alloys, and high-temp alloys

TungMeister

- Exchangeable-head end mill series offering a variety of head profiles, geometries, and sizes are available in grades that work in all material groups

- No setup time, allowing insert changes without removing the entire tool from the spindle.

- Reduced inventory and production cost

- Variable-pitch, variable-helix geometry eliminates chatter

- Offers a variety of head profiles

TungForce-Rec

- Indexable miniature end milling cutter with versatility

- Unique insert design allows high density cutter design and light cutting for high productivity and process security

- Provides excellent wall accuracy

Specials – profiling

- Tungaloy’s customized tooling solutions tailored to customer’s specific needs for high surface integrity and part precision in finish profiling operations.