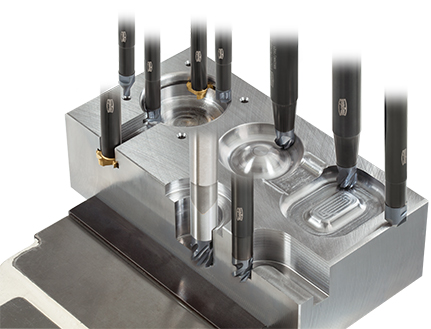

Endmill with exchangeable heads for reduced tool change time

Choose the best head-shank combination for your endmilling operation

Minimize setup time while maximizing your productivity

Applications & Features

Applications

Features

1. Wide range of geometries

• 45 kinds of geometries are available. The head indexing is easy and highly accurate with the precision thread.

2. Three kinds of shank material

• Users can choose the most suitable combination according to the machining parameters, length and application required.

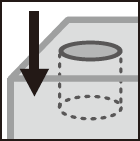

3. No setup time

Machine downtime is decreased considerably. Simplified setup since only the head is indexed.

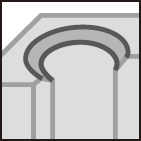

4. High accuracy and repeatability

Repeatability and accuracy are maintained due to full contact of both taper and face.

Heads & Grades

Inserts

Grades

AH725

![]()

![]()

![]()

![]()

- Nano-multilayered coating

- Priority on chipping and fracture resistance

AH715

![]()

![]()

![]()

![]()

![]()

- Nano-multilayered coating

- Excellent longer tool life than existing grade

GH130

![]()

![]()

![]()

- High chipping and fracture resistance

- Suitable for steel, stainless steel, and cast iron

GH730

![]()

![]()

![]()

![]()

![]()

- Good balance between wear and chipping resistance

- First choice for slotting of various materials

Tools

Shank Type

Straight neck and cylindrical shank

Straight shank and neck with coolant hole

Straight neck and weldon shank

High-rigidity shank

Straight shank and taper neck

Straight shank and taper neck with coolant hole

Practical examples

Example #1

| Part: | Gear |

| Material: | SCM420 / 18CrMo4 |

| Shank: | VSSD16L100S10-S (Steel, ø16 mm) |

| Head: | VEE160L12.0C60I04S10 (ø16 mm) |

| Grade: | AH715 |

| Cutting conditions: | Vc = 100 (m/min) fz = 0.09 (mm/t) ap = 10 (mm) ae = 0.1 (mm) Coolant: Wet |

Example #2

| Part: | Shaft |

| Material: | S45C / C45 |

| Shank: | VSSD10L075S06-S (Steel, ø10 mm) |

| Head: | VEH100L15.0R10I04S06 (ø10 mm) |

| Grade: | AH715 |

| Cutting conditions: | Vc = 100 (m/min) fz = 0.05 (mm/t) ap = 1 (mm) ae = 6 (mm) Coolant: Wet |

Example #3

| Part: | Rack |

| Material: | SCM440 / 42CrMo4 |

| Shank: | VSSD25L075S12-S (Steel, ø25 mm) |

| Head: | VEH200L30.0R05I04S12 (ø20 mm) |

| Grade: | AH715 |

| Cutting conditions: | Vc = 140 (m/min) fz = 0.08 (mm/t) ap = 24 (mm) ae = 5.5 (mm) Coolant: Wet |

Standard cutting conditions

Square - Shoulder milling

VEH, VEE: 3 flutes, VED / VEE: 4 flutes, VEE-A, VEE-I, VEE-R, VED-R, VEE-C

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Feed per tooth: fz (mm/t) | Depth of cut ap (mm) |

Width of cut ae(mm) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tool diameter: DC (mm) | ||||||||||||||

| 5 | 6 | 8 | 10 | 12 | 16 | 20 | 25 | 32 | ||||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 180 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 140 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 60 – 120 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 40 – 100 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 200 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 200 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

|

Aluminium alloys Si < 13% |

– | 200 – 700 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

| Aluminium alloys Si ≥ 13% |

– | 100 – 300 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.03 – 0.07 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.1 – 0.18 | 0.6 x DC | 0.25 x DC | |

VED / VEE: 6 flutes, VED / VEE: 8, 10 flutes, VED: 7, 9 flutes

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Feed per tooth: fz (mm/t) | Depth of cut ap (mm) |

Width of cut ae(mm) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tool diameter: DC (mm) | |||||||||||

| 8 | 10 | 12 | 16 | 20 | 25 | ||||||

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 60 – 120 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.6 x DC | 0.02 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 30 – 60 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.6 x DC | 0.02 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 80 – 160 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.6 x DC | 0.02 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 40 – 90 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 0.6 x DC | 0.02 x DC | |

Square - Slotting

VEH, VEE: 3 flutes, VED/VEE: 4 flutes, VEE-A, VEE-I, VEE-R, VEE-C

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Feed per tooth: fz (mm/t) | Depth of cut ap (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tool diameter: DC (mm) | |||||||||||||

| 5 | 6 | 8 | 10 | 12 | 16 | 20 | 25 | 32 | |||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 50 – 70 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 40 – 80 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 40 – 70 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 30 – 60 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 50 – 120 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 50 – 120 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

|

Aluminium alloys Si < 13% |

– | 130 – 400 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

| Aluminium alloys Si ≥ 13% |

– | 70 – 200 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 20 – 40 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 10 – 20 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 25 – 60 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 10 – 30 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.07 – 0.1 | 0.07 – 0.1 | 0.5 x DC | |

VED-RS

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Shoulder milling | Slotting | Depth of cut ap (mm) |

Width of cut ae (mm) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed per tooth: fz (mm/t) | |||||||||||

| Tool diameter: DC (mm) | |||||||||||

| 6 | 8 | 10 | 6 | 8 | 10 | ||||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 140 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 120 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 60 – 100 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 40 – 80 | 0.03 – 0.05 | 0.05 – 0.07 | 0.05 – 0.07 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.5 x DC | 0.15 x DC |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 140 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 140 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC | |

|

Aluminium alloys Si < 13% |

– | 200 – 500 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC |

| Aluminium alloys Si ≧ 13% |

– | 100 – 200 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | 0.5 x DC | 0.15 x DC | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 60 | 0.03 – 0.05 | 0.05 – 0.07 | 0.05 – 0.07 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.5 x DC | 0.15 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 30 | 0.03 – 0.05 | 0.05 – 0.07 | 0.05 – 0.07 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.5 x DC | 0.15 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 60 | 0.03 – 0.05 | 0.05 – 0.07 | 0.05 – 0.07 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.5 x DC | 0.15 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 40 | 0.03 – 0.05 | 0.03 – 0.05 | 0.05 – 0.07 | 0.03 – 0.04 | 0.03 – 0.04 | 0.03 – 0.04 | 0.5 x DC | 0.15 x DC | |

Face milling

VFM

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Feed per tooth: fz (mm/t) | Depth of cut ap (mm) | Width of cut ae(mm) | |||

|---|---|---|---|---|---|---|---|---|---|

| Tool diameter: DC (mm) | |||||||||

| 12 | 16 | 20 | 25 | ||||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 180 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 140 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 60 – 120 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 40 – 100 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 200 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 200 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

|

Aluminium alloys Si < 13% |

– | 200 – 700 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

| Aluminium alloys Si ≥ 13% |

– | 100 – 300 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.1 – 0.17 | 1 | 0.7 x DC | |

High feed milling

VFX: 2, 4, 6 flutes

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | ø10 | ø12 | ø16 | ø20 | Width of cut ae (mm) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed per tooth fz (mm/t) |

Depth of cut ap (mm) |

Feed per tooth fz (mm/t) |

Depth of cut ap (mm) |

Feed per tooth fz (mm/t) |

Depth of cut ap (mm) |

Feed per tooth fz (mm/t) |

Depth of cut ap (mm) |

|||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 100 – 200 | 0.3 – 0.7 | 0.5 | 0.4 – 0.8 | 0.5 | 0.5 – 0.9 | 0.75 | 0.6 – 1 | 1 | 0.6 x DC |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 80 – 180 | 0.2 – 0.6 | 0.5 | 0.3 – 0.7 | 0.5 | 0.4 – 0.8 | 0.75 | 0.5 – 0.9 | 1 | 0.6 x DC | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 80 – 160 | 0.2 – 0.5 | 0.4 | 0.2 – 0.5 | 0.4 | 0.3 – 0.6 | 0.5 | 0.3 – 0.6 | 0.75 | 0.6 x DC | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 60 – 100 | 0.2 – 0.6 | 0.4 | 0.2 – 0.6 | 0.4 | 0.3 – 0.7 | 0.5 | 0.3 – 0.7 | 0.75 | 0.6 x DC |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 100 – 220 | 0.3 – 0.7 | 0.5 | 0.4 – 0.8 | 0.75 | 0.5 – 0.9 | 0.75 | 0.6 – 1 | 1 | 0.6 x DC |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 100 – 220 | 0.2 – 0.6 | 0.5 | 0.3 – 0.7 | 0.75 | 0.4 – 0.8 | 0.75 | 0.5 – 0.9 | 1 | 0.6 x DC | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.2 – 0.5 | 0.4 | 0.2 – 0.5 | 0.4 | 0.2 – 0.6 | 0.5 | 0.2 – 0.6 | 0.5 | 0.25 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.1 – 0.3 | 0.3 | 0.1 – 0.3 | 0.3 | 0.1 – 0.3 | 0.4 | 0.1 – 0.3 | 0.4 | 0.25 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.2 – 0.4 | 0.3 | 0.2 – 0.4 | 0.3 | 0.3 – 0.5 | 0.4 | 0.3 – 0.5 | 0.4 | 0.45 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.1 – 0.2 | 0.2 | 0.1 – 0.2 | 0.2 | 0.1 – 0.3 | 0.3 | 0.1 – 0.3 | 0.3 | 0.25 x DC | |

Please note that the feed per tooth should not exceed the maximum feed per tooth for each product.

Ball - Profiling for roughing

VBB-BM / BG / SG, VBD-BG, VBE-BGA

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Feed per tooth: fz (mm/t) | Depth of cut ap (mm) | Pick feed Pf (mm) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tool diameter: DC (mm) | |||||||||||||

| 5 | 6 | 8 | 10 | 12 | 16 | 20 | 25 | ||||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 100 – 200 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 80 – 180 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 80 – 160 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 60 – 100 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 100 – 220 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 100 – 220 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC | |

|

Aluminium alloys Si < 13% |

– | 200 – 700 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC |

| Aluminium alloys Si ≥ 13% |

– | 100 – 300 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.4 x DC | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.2 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.2 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.2 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.03 – 0.07 | 0.03 – 0.07 | 0.04 – 0.08 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.08 – 0.15 | 0.08 – 0.15 | 0.3 x DC | 0.2 x DC | |

Ball - Profiling for semi-finishing and finishing

VBB-BM / BG / SG, VBD-BG, VBE-BGA

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Feed per tooth: fz (mm/t) | Depth of cut ap (mm) |

Pick feed Pf (mm) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tool diameter: DC (mm) | |||||||||||||

| 5 | 6 | 8 | 10 | 12 | 16 | 20 | 25 | ||||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 120 – 250 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 100 – 220 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 100 – 200 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 80 – 120 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 120 – 280 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 120 – 280 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC | |

|

Aluminium alloys Si < 13% |

– | 300 – 1000 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC |

| Aluminium alloys Si ≥ 13% |

– | 150 – 400 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.1 x DC | 0.15 x DC | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 50 – 100 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.08 x DC | 0.1 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 30 – 50 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.08 x DC | 0.1 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 50 – 100 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.08 x DC | 0.1 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 30 – 80 | 0.04 – 0.09 | 0.04 – 0.09 | 0.06 – 0.11 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.16 | 0.1 – 0.18 | 0.1 – 0.18 | 0.08 x DC | 0.1 x DC | |

Radius - Shoulder milling

VRB, VRC, VRD

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Feed per tooth: fz (mm/t) | Depth of cut ap (mm) |

Width of cut ae(mm) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Tool diameter: DC (mm) | ||||||||||

| 8 | 10 | 12 | 16 | 20 | ||||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 180 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 140 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 60 – 120 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 40 – 100 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 200 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 200 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

|

Aluminium alloys Si < 13% |

– | 200 – 700 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

| Aluminium alloys Si ≥ 13% |

– | 100 – 300 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.05 – 0.09 | 0.07 – 0.12 | 0.08 – 0.13 | 0.09 – 0.15 | 0.1 – 0.17 | 0.6 x DC | 0.25 x DC | |

Radius - Slotting

VRB, VRC, VRD

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Feed per tooth: fz (mm/t) | Depth of cut ap (mm) |

||||

|---|---|---|---|---|---|---|---|---|---|

| Tool diameter: DC (mm) | |||||||||

| 8 | 10 | 12 | 16 | 20 | |||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 50 – 70 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 40 – 80 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 40 – 70 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 30 – 60 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 50 – 120 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 50 – 120 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

|

Aluminium alloys Si < 13% |

– | 130 – 400 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

| Aluminium alloys Si ≥ 13% |

– | 70 – 200 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 20 – 40 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 10 – 20 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 25 – 60 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 10 – 30 | 0.03 – 0.04 | 0.04 – 0.05 | 0.05 – 0.06 | 0.06 – 0.08 | 0.07 – 0.1 | 0.5 x DC | |

Barrel, Bull nose, Lens - Profiling

VBO, VBN, VBL

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Feed per tooth: fz (mm/t) | Cusp height (mm) | ||

|---|---|---|---|---|---|---|---|

| Tool diameter: DC (mm) | |||||||

| 10 | 12 | 16 | |||||

|

Low carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 100 – 200 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

| High carbon steel SCM440, SCr415, etc. 42CrMo4, 15Cr3, etc. |

– 300 HB | 80 – 180 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 80 – 160 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 60 – 100 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc. |

150 – 250 HB | 100 – 220 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

| Ductile cast iron FCD400, etc. 400-15S, etc. |

150 – 250 HB | 100 – 220 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

|

Aluminium alloys Si < 13% |

– | 200 – 700 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

| Aluminium alloys Si ≥13% |

– | 100 – 300 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

| Heat-resistant alloys Inconel718, etc. |

– 40 HRC | 20 – 40 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

|

Hardened steel SKD61, SKT4, etc. X40CrMoV5-1, 55NiCrMoV6, etc. |

– | 40 – 80 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 |

| Hardened steel SKD11, SKH, etc. X153CrMoV12, HS18-0-1, etc. |

50 – 60 HRC | 20 – 60 | 0.05 – 0.1 | 0.06 – 0.11 | 0.07 – 0.13 | 0.1 | |

Chamfering and countersinking (Milling, Z-feed chamfering)

VCA, VCW, VCR

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 60 – 100 | 0.03 – 0.06 |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 50 – 80 | 0.03 – 0.06 | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 40 – 70 | 0.03 – 0.06 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 30 – 50 | 0.03 – 0.06 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 120 | 0.03 – 0.06 |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 120 | 0.03 – 0.06 | |

|

Aluminium alloys | – | 100 – 200 | 0.04 – 0.08 |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 30 – 50 | 0.025 – 0.05 |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.02 – 0.04 | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 30 – 50 | 0.025 – 0.05 |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 40 | 0.02 – 0.04 |

Spot drill

VCP, VDS

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

|---|---|---|---|---|

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 60 – 100 | 0.06 – 0.12 |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 50 – 80 | 0.06 – 0.12 | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 40 – 70 | 0.06 – 0.12 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 30 – 50 | 0.06 – 0.12 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 120 | 0.06 – 0.12 |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 120 | 0.06 – 0.12 | |

|

Aluminium alloys | – | 100 – 200 | 0.08 – 0.16 |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 30 – 50 | 0.05 – 0.1 |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.04 – 0.08 | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 30 – 50 | 0.05 – 0.1 |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 40 | 0.04 – 0.08 |

Center drill

VDP

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Feed : f (mm/rev) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VDP107 | VDP165 | VDP2 | VDP3 | VDP4 | VDP5 | VDP6 | ||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 40 – 80 | 0.02 – 0.04 | 0.025 – 0.05 | 0.025 – 0.05 | 0.04 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.06 – 0.12 |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 30 – 50 | 0.02 – 0.04 | 0.025 – 0.05 | 0.025 – 0.05 | 0.04 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.06 – 0.12 | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 20 – 30 | 0.02 – 0.04 | 0.025 – 0.05 | 0.025 – 0.05 | 0.04 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.06 – 0.12 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 15 – 25 | 0.015 – 0.03 | 0.02 – 0.04 | 0.02 – 0.04 | 0.04 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.06 – 0.12 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 60 – 100 | 0.02 – 0.04 | 0.025 – 0.05 | 0.025 – 0.05 | 0.05 -0.09 | 0.07 – 0.012 | 0.07 – 0.12 | 0.12 – 0.18 |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 60 – 100 | 0.02 – 0.04 | 0.025 – 0.05 | 0.025 – 0.05 | 0.04 – 0.08 | 0.05 – 0.1 | 0.05 – 0.1 | 0.1 – 0.15 | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 15 – 25 | 0.01 – 0.02 | 0.01 – 0.02 | 0.015 – 0.03 | 0.04 – 0.07 | 0.04 – 0.07 | 0.04 – 0.07 | 0.04 – 0.07 |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 10 – 20 | 0.01 – 0.02 | 0.01 – 0.02 | 0.015 – 0.03 | 0.03 – 0.06 | 0.03 – 0.06 | 0.03 – 0.06 | 0.03 – 0.06 | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 15 – 25 | – | – | – | 0.04 – 0.07 | 0.04 – 0.07 | 0.04 – 0.07 | 0.04 – 0.07 |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 10 – 20 | – | – | – | 0.03 – 0.06 | 0.03 – 0.06 | 0.03 – 0.06 | 0.03 – 0.06 | |

—0.03 – 0.060.03 – 0.060.03 – 0.060.03 – 0.06

Counterboring

VGC

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|---|---|---|---|---|

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 40 – 80 | 0.04 – 0.08 |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 30 – 50 | 0.04 – 0.08 | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 20 – 30 | 0.04 – 0.08 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 15 – 25 | 0.04 – 0.08 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 60 – 100 | 0.05 – 0.09 |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 60 – 100 | 0.04 – 0.08 | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 15 – 25 | 0.04 – 0.07 |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 10 – 20 | 0.03 – 0.06 | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 15 – 25 | 0.04 – 0.07 |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 10 – 20 | 0.03 – 0.06 |

When drilling, pecking operation should be applied with the depth of 0.3 – 0.5 mm per step.

Apply the same cutting conditions as the VEE type head when conducting shoulder milling or slotting operations.

Slotting

| ISO | Workpiece material | Hardness | VST | VTB | ||

|---|---|---|---|---|---|---|

| Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

Cutting speed Vc (m/min) |

Feed per tooth fz (mm/t) |

|||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 180 | 0.05 – 0.15 | 80 – 180 | 0.08 – 0.18 |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 120 | 0.04 – 0.12 | 60 – 120 | 0.05 – 0.15 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 50 – 120 | 0.04 – 0.12 | 50 – 120 | 0.05 – 0.15 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 100 – 200 | 0.05 – 0.15 | 100 – 200 | 0.08 – 0.18 |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 100 – 200 | 0.04 – 0.12 | 100 – 200 | 0.05 – 0.15 | |

|

Aluminium alloys Si < 13% |

– | 200 – 600 | 0.05 – 0.15 | 200 – 600 | 0.08 – 0.18 |

| Aluminium alloys Si ≥ 13% |

– | 100 – 300 | 0.03 – 0.13 | 100 – 300 | 0.05 – 0.15 | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 60 | 0.04 – 0.12 | 40 – 60 | 0.05 – 0.15 |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 15 – 35 | 0.02 – 0.1 | 15 – 35 | 0.02 – 0.1 | |

Indexable modular head

HPAV06-S

| ISO | Workpiece materials | Hardness | Priority | Grades | Cutting speed Vc (m/min) | Feed per tooth fz (mm/t) |

|

|---|---|---|---|---|---|---|---|

|

Low carbon steel S15C / C15E4, SS400 / E275A, etc. |

– 200 HB | First choice | AH3225 | 230 – 430 | 0.07 – 0.12 | |

| Carbon steel and alloy steel S55C / C55, SCM440 / 42CrMo4, etc. |

– 300 HB | First choice | AH3225 | 150 – 350 | 0.07 – 0.12 | ||

| Prehardend steel NAK80, PX5, etc. |

30 – 40 HRC | First choice | AH3225 | 100 – 230 | 0.07 – 0.12 | ||

|

Stainless steel SUS304 / X5CrNi18-9, SUS316 / X5CrNiMo17-12-3, etc. |

– | First choice | AH3135 | 150 – 220 | 0.06 – 0.1 | |

|

Grey cast iron FC250 / 250, FC300 / 300, etc. |

150 – 250 HB | First choice | AH120 | 200 – 330 | 0.07 – 0.12 | |

| Ductile cast iron FCD400, FCD600 / 600-3, etc. |

150 – 250 HB | First choice | AH120 | 150 – 240 | 0.07 – 0.12 | ||

|

Aluminium alloys Si < 13% |

– | First choice | KS05F | 650 – 1000 | 0.07 – 0.12 | |

| Aluminium alloys Si ≥ 13% |

– | First choice | KS05F | 100 – 230 | 0.04 – 0.12 | ||

|

Titanium alloys Ti-6AI-4V, etc. |

– 40 HRC | First choice | AH130 | 40 – 90 | 0.04 – 0.1 | |

| Superalloys Inconel718, etc. |

– 40 HRC | First choice | AH130 | 45 – 65 | 0.04 – 0.09 | ||

|

Hardened steel | SKD61 / X40CrMoV5-1, etc. |

40 – 50 HRC | First choice | AH120 | 45 – 70 | 0.04 – 0.08 |

| SKD11 / X153CrMoV12, etc. |

50 – 60 HRC | First choice | AH120 | 40 – 65 | 0.04 – 0.06 | ||

Threading

VMT, VTR

| ISO | Material | Condition | Tensile strength [N/mm2] | Hardness | Cutting speed (m/min) |

Tool dia. (mm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Feed (mm/t) | ||||||||||

| AH725 | ø10 | ø12 | ø15.4, ø15.7, ø16 | ø21.7 | ||||||

|

Non-alloy steel and cast steel, free cutting steel | < 0.25 %C | Annealed | 420 | 125 HB | 100 – 250 | 0.08 | 0.09 | 0.12 | 0.15 |

| ≥ 0.25 %C | Annealed | 650 | 190 HB | 80 – 210 | 0.08 | 0.09 | 0.12 | 0.15 | ||

| < 0.55 %C | Quenched and tempered | 850 | 250 HB | 65 – 170 | ||||||

| ≥ 0.55 %C | Annealed | 750 | 220 HB | 110 – 180 | 0.07 | 0.08 | 0.1 | 0.12 | ||

| Quenched and tempered | 1000 | 300 HB | 95 – 160 | 0.07 | 0.08 | 0.1 | 0.12 | |||

| Low alloy steel and cast steel (less than 5% of alloying elements) |

Annealed | 600 | 200 HB | 90 – 160 | 0.05 | 0.05 | 0.07 | 0.08 | ||

| Quenched and tempered | 930 | 275 HB | 65 – 200 | 0.05 | 0.05 | 0.07 | 0.08 | |||

| 1000 | 300 HB | 70 – 210 | 0.05 | 0.05 | 0.07 | 0.08 | ||||

| 1200 | 350 HB | 95 – 160 | 0.05 | 0.05 | 0.07 | 0.08 | ||||

| High alloyed steel, cast steel, and tool steel | Annealed | 680 | 200 HB | 130 – 170 | 0.05 | 0.05 | 0.07 | 0.08 | ||

| Quenched and tempered | 1100 | 325 HB | 75 – 100 | 0.05 | 0.05 | 0.07 | 0.08 | |||

| Stainless steel and cast steel | Ferritic/martensitic | 680 | 200 HB | 110 – 170 | 0.05 | 0.05 | 0.07 | 0.08 | ||

| Martensitic | 820 | 240 HB | 70 – 155 | 0.05 | 0.05 | 0.07 | 0.08 | |||

|

Stainless steel | Annealed | 600 | 180 HB | 85 – 100 | 0.05 | 0.05 | 0.07 | 0.08 | |

|

Cast iron nodular (GGG) | Ferritic/martensitic | 180 HB | 120 – 160 | 0.08 | 0.09 | 0.12 | 0.15 | ||

| Pearlitic | 260 HB | 75 – 160 | 0.08 | 0.09 | 0.12 | 0.15 | ||||

| Grey cast iron (GG) | Ferritic | 160 HB | 70 – 150 | 0.08 | 0.09 | 0.12 | 0.15 | |||

| Pearlitic | 250 HB | 110 – 140 | 0.08 | 0.09 | 0.12 | 0.15 | ||||

| Malleable cast iron | Ferritic | 130 HB | 120 – 160 | 0.08 | 0.09 | 0.12 | 0.15 | |||

| Pearlitic | 230 HB | 110 – 140 | 0.08 | 0.09 | 0.21 | 0.15 | ||||

|

Aluminium-wrought alloy | Not cureable | 60 HB | 160 – 300 | 0.08 | 0.09 | 0.12 | 0.15 | ||

| Cured | 100 HB | |||||||||

| Aluminium-cast, alloyed | ≤12% Si | Not cureable | 75 HB | 150 – 350 | 0.08 | 0.09 | 0.12 | 0.15 | ||

| Cured | 90 HB | |||||||||

| >12% Si | High temperature | 130 HB | 100 – 250 | 0.05 | 0.05 | 0.07 | 0.08 | |||

| Copper alloys | >1% Pb | Free cutting | 110 HB | |||||||

| Brass | 90 HB | |||||||||

| Electrolitic copper | 100 HB | |||||||||

| Non-metallic | Duroplastics, fiber plastics | 100 – 400 | 0.11 | 0.12 | 0.15 | 0.18 | ||||

| Hard rubber | ||||||||||

|

High temp. alloys | Fe based | Annealed | 200 HB | ||||||

| Cured | 280 HB | |||||||||

| Ni or Co based | Annealed | 250 HB | 20 – 80 | 0.03 | 0.03 | 0.04 | 0.04 | |||

| Cured | 350 HB | |||||||||

| Cast | 320 HB | |||||||||

| Titanium Ti alloys | RM 400 | |||||||||

| Alpha+beta alloys cured | RM 1050 | 20 – 80 | 0.03 | 0.03 | 0.04 | 0.04 | ||||

|

Hardened steel | Hardened | 55 HRC | 55 – 65 | ||||||

| Hardened | 60 HRC | 45 – 55 | ||||||||

| Chilled cast iron | Cast | 400 HB | 90 – 105 | |||||||

| Cast iron | Hardened | 55 HRC | 55 – 65 | |||||||

Multi Functional

VVFH

| ISO | Workpiece material | Hardness | Cutting speed Vc (m/min) | Drilling | Shoulder milling | Slotting | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Feed per revolution: f (mm/rev) | Feed per tooth: fz (mm/t) | |||||||||

| Tool diameter: DC (mm) | ||||||||||

| 6 | 8 | 10 | 6 | 8 | 10 | |||||

|

Carbon steel S45C, S55C, etc. C45, C55, etc. |

– 300 HB | 80 – 180 | 0.12 – 0.18 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

| Alloy steel SCM440, SCr420, etc. 42CrMo4, 20Cr4, etc. |

– 300 HB | 60 – 140 | 0.12 – 0.18 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | |

| Prehardened steel PX5, NAK80, etc. |

30 – 40 HRC | 60 – 120 | 0.12 – 0.18 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | |

|

Stainless steel SUS304, SUS316, etc. X5CrNi18-9, X5CrNiMo17-12-2, etc. |

– 200 HB | 40 – 100 | 0.09 – 0.15 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

|

Grey cast iron FC250, FC300, etc. 250, 300, etc., GG250, GG300, etc. |

150 – 250 HB | 80 – 200 | 0.12 – 0.18 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

| Ductile cast iron FCD450, etc. 450-10S, etc., GGG450, etc. |

150 – 250 HB | 80 – 200 | 0.12 – 0.18 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | |

|

Aluminium alloys Si < 13% |

– | 200 – 700 | 0.09 – 0.15 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

| Aluminium alloys Si ≧ 13% |

– | 100 – 300 | 0.09 – 0.15 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | |

|

Titanium alloys Ti-6Al-4V, etc. |

– 40 HRC | 40 – 80 | 0.02 – 0.05 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

| Heat-resistant alloys Inconel 718, etc. |

– 40 HRC | 20 – 40 | 0.02 – 0.05 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 | |

|

Hardened steel SKD6, SKT4, etc. 55NiCrMoV7, etc. |

40 – 50 HRC | 40 – 80 | 0.06 – 0.09 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.03 – 0.04 | 0.03 – 0.04 | 0.04 – 0.05 |

| Hardened steel SKD11, SKH51, etc. HS6-5-2, etc. |

50 – 60 HRC | 20 – 60 | 0.06 – 0.09 | 0.03 – 0.07 | 0.05 – 0.09 | 0.07 – 0.12 | 0.04 – 0.05 | 0.04 – 0.05 | 0.04 – 0.05 | |

For more information about this product, visit our online e-catalog or download the product report: