Iwaki, October 2020 — Tungaloy has expanded its ISO-EcoTurn economical turning insert and holder series by adding toolholders for VNMG1204 inserts for manufacturers seeking both cost efficiency and performance with Swiss-style machining.

ISO-EcoTurn inserts, while downsized for cost efficiency, feature the identical chipbreaker geometry and thickness of regular-sized inserts to maintain the same cutting performance at a depth of cut up to 3.0 mm (.118″). In addition, toolholders with high pressure through-coolant capability are available for high-temperature alloy and other difficult-to-cut material applications where chip control is typically challenging.

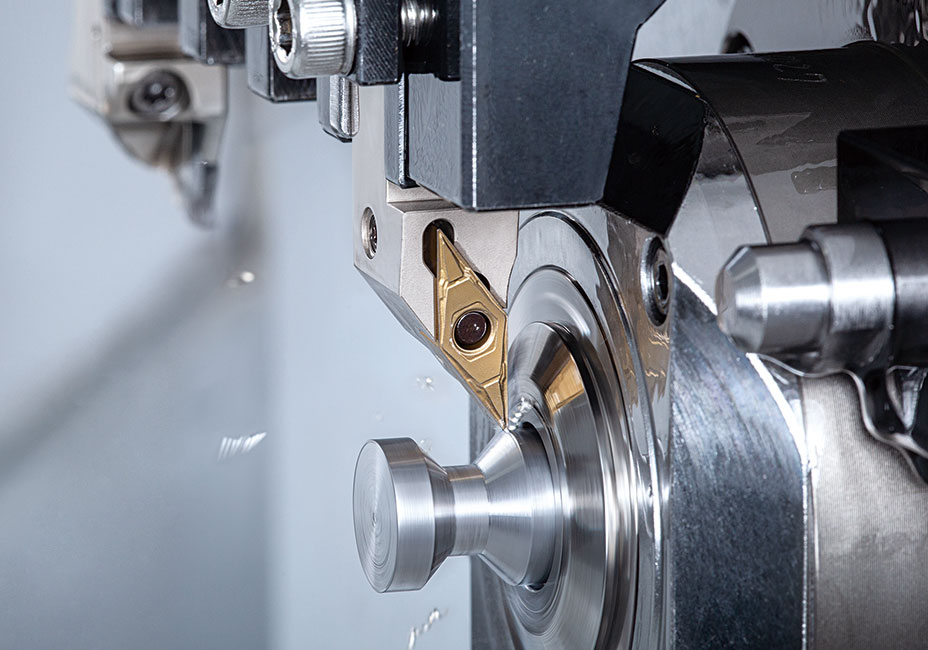

The latest ISO-EcoTurn toolholder for VNMG1204 insert is developed for the use on Swiss machines: its lever lock clamp screw is located on the side of the holder, enabling better accessibility for easy insert replacements while the holder is still on the machine’s tool post. The shank is available in either 12×12 (1/2″) or 16×16 (5/8″) size and can be used on various machine models. In addition, 16×16 shank holders are also available in an offset-style version for the use on standard CNC lathes and turning centers.