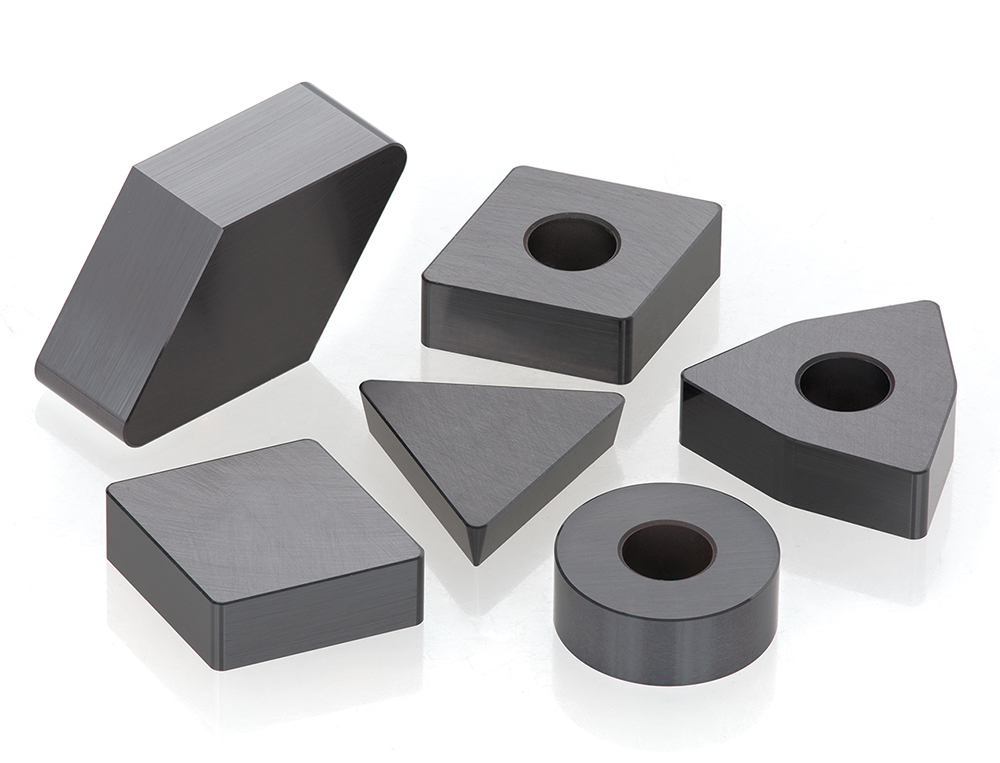

Ceramic inserts for hardened steel machining

Expanded ceramic insert range for continuous cuts of hardened steel parts

Applications & Features

Applications

Features

1. Application range for hardened steel machining

- Suitable for medium speed continuous machining

- Surface quality < Rz 6.3 μm at various depths of cut

- Higher wear resistance than CBN for part hardness less than 55 HRC

Grades

Practical examples

Example #1

General Engineering

| Part: | Guide pin |

| Material: | D2 tool steel (60 HRC) |

| Insert: | DNGA150408 |

| Grade: | LX10 |

| Toolholder: | ADJNR2525M15 |

| Cutting conditions: | Vc = 120 (m/min) f = 0.2 (mm/rev) ap = 1 (mm) Application: External turning Coolant: Wet |

Example #2

General Engineering

| Part: | Housing |

| Material: | 16MnCr5 (54 HRC) |

| Insert: | TNGA160412 |

| Grade: | LX10 |

| Toolholder: | A32S-ATFNL16-D400 |

| Cutting conditions: | Vc = 80 (m/min) f = 0.2 (mm/rev) ap = 0.3(mm) Application: Internal turning Coolant: Wet |

Standard cutting conditions

| ISO | Grade | Workpiece materials |

Cutting mode | Coolant | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

|---|---|---|---|---|---|---|---|

| LX10 | Hardened steel | Continuous | Wet | 50 – 150 | 0.05 – 0.2 | 0.05 – 2 |

For more information about this product, visit our online e-catalog or download the product report: