New DLC coating grade for Turning & Threading

Excellent built-up edge resistance and high surface quality

Applications & Features

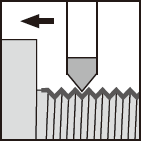

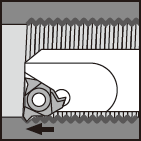

Applications

Features

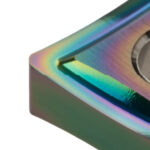

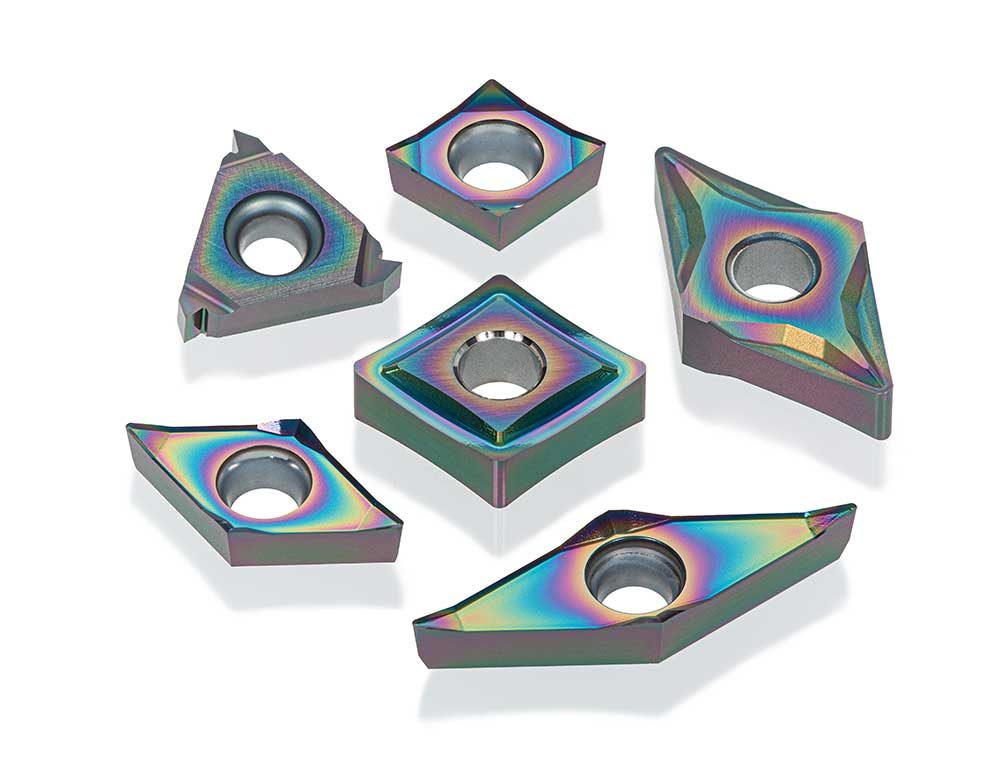

DLC coated inserts

Tungaloy original DLC coating grade for non-ferrous alloys

- Excellent built-up edge resistance achieves high quality glossy machined surface.

- The coating with high hardness and excellent heat resistance reduce wear.

- Outstanding coating adhesion technology provides stable and reliable machining.

Excellent built-up edge resistance and high surface quality

Excellent built-up edge resistance achieves high quality glossy machined surface.

Excellent wear resistance

The coating with high hardness and excellent heat resistance reduce wear progress.

Stable and reliable machining

Outstanding coating adhesion technology provides stable and reliable machining.

Grades

DS2005

![]()

- Excellent wear resistance ensures stable long life in high-speed machining of non-ferrous metals.

DS2015

![]()

- Well balanced wear and chipping resistance perform stable and reliable machining in a wide range of machining applications.

Practical examples

Example #1

| Workpiece type: | Vacuum pump part |

| Workpiece material: | A6061 / AlMg1SiCu |

| Insert: | CNGG120404-28 |

| Grade: | DS2005 |

| Cutting conditions: | Vc = 330 (m/min) f = 0.35 (mm/rev) ap = 0.2 (mm) Coolant: Wet |

Example #2

| Workpiece type: | Machine part |

| Workpiece material: | C1011 / Copper |

| Insert: | CNGG120408-28 |

| Grade: | DS2005 |

| Cutting conditions: | Vc = 270 (m/min) f = 0.15 (mm/rev) ap = 1 (mm) Coolant: Wet |

Example #3

| Workpiece type: | Shaft |

| Workpiece material: | A5052 / ALMg2.5 |

| Insert: | 16IRA60 |

| Grade: | DS2015 |

| Cutting conditions: | Vc = 150 (m/min) Pitch = 1 Coolant: Wet |

Standard cutting conditions

| ISO | Workpiece materials | Chipbreaker | Grade | Cutting speed Vc (m/min) |

Feed f (mm/rev) |

Depth of cut ap (mm) |

|---|---|---|---|---|---|---|

|

Aluminum alloys (Si ≤ 12%) |

AL | DS2005 | 100 – 1200 | 0.1 – 0.5 | 0.5 – 5 |

| 28 | DS2005 | 100 – 1200 | 0.1 – 0.5 | 0.5 – 3 | ||

| Aluminum alloys (Si ≥ 12%) |

AL | DS2005 | 100 – 300 | 0.1 – 0.5 | 0.5 – 5 | |

| 28 | DS2005 | 100 – 300 | 0.1 – 0.5 | 0.5 – 3 | ||

| Copper and copper alloys | AL | DS2005 | 100 – 300 | 0.1 – 0.5 | 0.5 – 5 | |

| 28 | DS2005 | 100 – 300 | 0.1 – 0.5 | 0.5 – 3 |

| ISO | Workpiece materials | Grade | Cutting speed Vc (m/min) |

|---|---|---|---|

|

Non-ferrous metal | DS2015 | 100 – 500 |

For more information about this product, visit our online e-catalog or download the product report: