TungCap Cost Saving Simulator

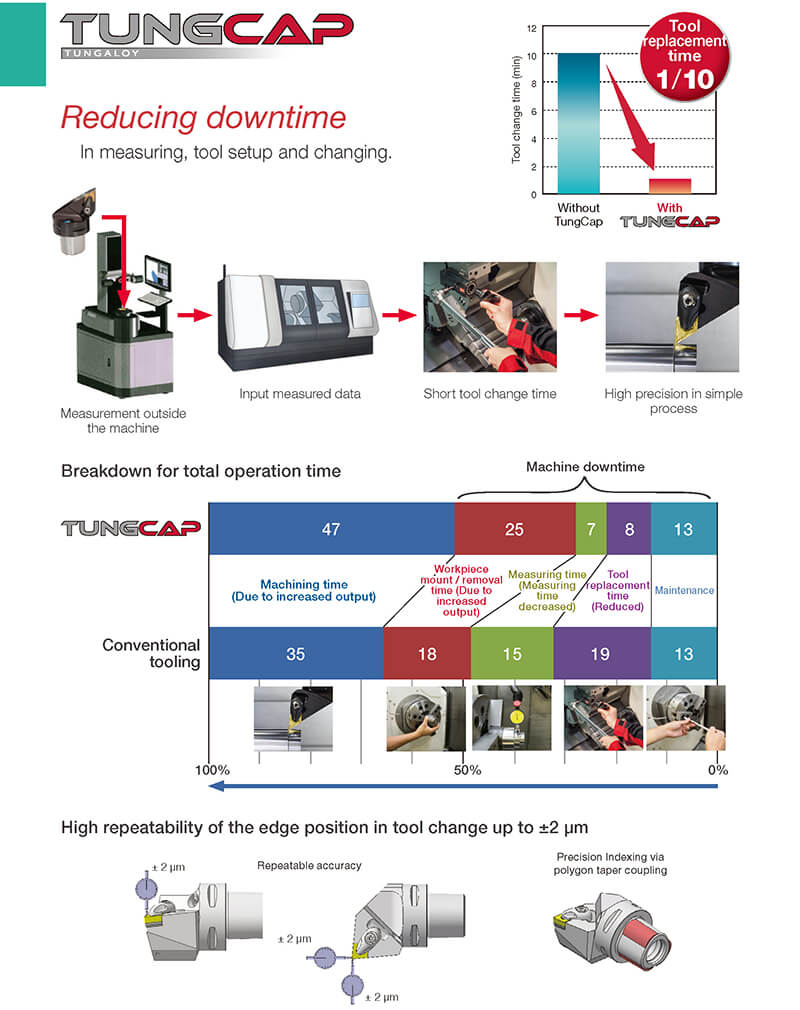

TungCap quick change tooling system is a great cost saver for CNC lathe and multi task machine operations, which allows streamlined tool change processes and maximum machine utilization.

This simulator allows you to have an insight on how much man-hours and costs TungCap tooling system can save, as well as productivity you can improve.

Simply enter your current data in the cells below, the simulator will automatically calculate the man-hours, costs, and productivity you can improve annually with TungCap.

Tool change operations by TungCap tooling

Data for routine insert change

TungCap tooling will be saving …

Labor costs |

38,333.333USD per year |

|---|---|

Machining time (in hours) |

1,533.333hours per year |

(of which hours saved from insert changes+offsetting) |

1,000hours |

(of which hours save from tool setup change) |

533.333hours |

Cost saved for test cut workpieces |

1,760USD per year |

Total value of additional parts produced annually for the time saved |

36,800USD per year |

(Total number of additional parts produced annually for the time saved) |

46,000units per year |

Total costs saved by TungCap tooling |

76,893.333USD per year |

Tool change operations by TungCap tooling